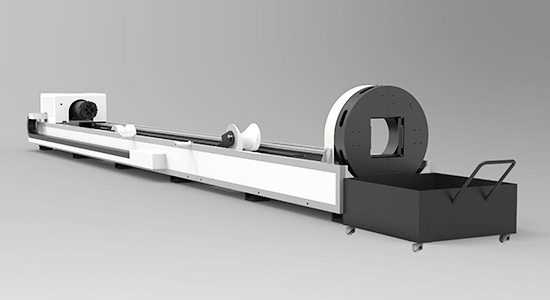

iGR-E(+T) Series

Exchange Platform Board and Tube Integrated Machine

Plate and tube dual-purpose fiber laser cutting machine, can achieve the cutting of two different profiles on the same machine tool, can cut metal sheet and pipe (square pipe, round pipe, channel steel, Angle steel, etc.). The addition of the exchange platform, no need to wait for the blanking time, can maximize the production line rate, a multi-purpose machine, high cost performance, high precision, full function, easy to use.

Exchange Table Fiber Laser Cutting Machine is equipped with two cutting pallets which can be automatically switched. When one is used for cutting, the other one can be loaded or unloaded with sheets.The laser cutter provides high cutting efficiency and precision, smooth cutting, clean, no burr, low material loss, small heat-affected zone and nearly no thermal deformation. It is suitable for large-scale continuous processing and is the preferred equipment for metal fabricators.

PG Tuck –

Well packaged with perfect condition. Easy to make it work. I cut a variety of thickness stainless steel sheet and pipewith no problems so far.

Melodee –

We have purchased two machines from IGOLDEN, and we are really happy with the machines and support from the sales. Let me introduce you to my friend Davor. He is interested in buying the fiber laser cutting machine from you.

Abdul –

Grazyna –

I inform you that we have already carried out tests with carbon steel and it worked perfectly. We have already scheduled the training for the personnel who will operate it and we are also going to carry out tests with stainless steel. But everything looks very good.

Ernestina –

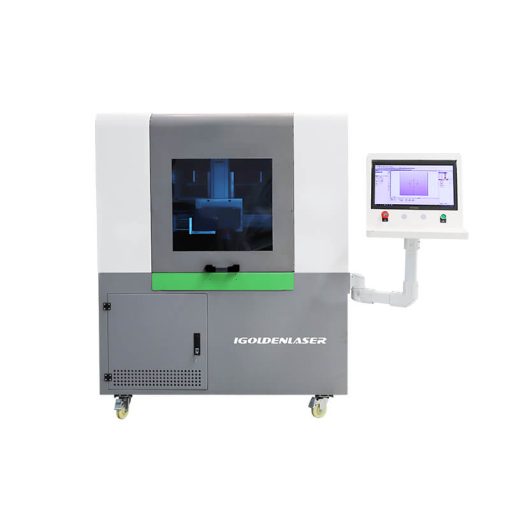

I am a newcomer to the laser cutting industry. I bought a small CNC laser cutting machine. The price of this machine is very cheap, and the delivery time is very fast. My machine was delivered to me smoothly and it is in IGOLDEN. Under the guidance of our engineers, I assembled the machine and performed my first attempt at laser cutting perfectly.

Taren –

I have been in the laser cutting industry for many years. I have always used laser machines to process sheet metal. In order to expand the scale of the factory, I bought a CNC laser cutting machine from IGOLDENCNC some time ago. The laser cutting machine price is so attractive, it is cheaper than all the laser machines I bought before, and when I received the goods, this machine is very beautiful and its performance is also very good, I am very satisfied.

Franklin –

I selected a lot of CNC laser cutting machine suppliers on the Internet, and finally, I chose IGOLDENLASER because it is very professional.

Aimee –

I like this laser metal cutting machine very much, it allows me to quickly realize the metal cutting function.

Sonja –

We have purchased two machines from IGOLDEN, and we are really happy with the machines and support from the sales. Let me introduce you to my friend . He is interested in buying the fiber laser cutting machine from you.

Renee –

This metal sheet and pipe laser cutting machine has transformed our fabrication process! The cutting speed and accuracy are incredible, allowing us to handle both sheets and pipes with ease. Highly recommend it for any metalworking shop!

Carrol –

I’m extremely satisfied with this laser cutter! It provides clean, precise cuts on both metal sheets and pipes. The dual functionality saves us so much time and space in the shop. The setup was straightforward, and the software is user-friendly.

Raymundo –

This machine has exceeded my expectations! The versatility to cut various shapes and sizes is fantastic. It’s robust and performs exceptionally well on different materials. Customer support has also been great in assisting with any questions.

Salvador –

This machine has exceeded my expectations! The versatility to cut various shapes and sizes is fantastic. It’s robust and performs exceptionally well on different materials. Customer support has also been great in assisting with any questions.

Dillon –

This laser cutting machine is a workhorse! It’s reliable and has significantly increased our production capacity. The safety features are impressive, and I appreciate how easy it is to maintain.

Constance –

Solid performance and very efficient! The only reason I’m not giving it five stars is that it can be a bit noisy during operation. However, the quality of cuts and the machine’s capabilities make it well worth it.

Ellis –

Great machine overall! It handles large jobs efficiently, and the cut quality is top-notch. There was a bit of a learning curve with the software, but once I got accustomed to it, everything ran smoothly.

Wolfgang –

The tube and plate laser cutting machine has significantly improved our production efficiency. The precision and speed are unmatched, allowing us to meet tight deadlines without compromising quality.

Merry –

The tube and plate laser cutting machine has significantly improved our production efficiency. The precision and speed are unmatched, allowing us to meet tight deadlines without compromising quality.

Erin –

This machine offers exceptional versatility, handling both tubes and plates seamlessly. The intuitive interface and robust performance make it a valuable addition to our manufacturing process.

Veronique –

We recently purchased this laser cutting machine for our fabrication shop, and it has exceeded our expectations. The exchange worktable feature significantly improves our workflow, allowing us to load and unload materials quickly. The cutting accuracy is impressive, and we’ve noticed a substantial increase in productivity. Highly recommend!

Jon –

We’ve been using this laser cutting machine for several months, and it has been a reliable workhorse in our shop. The exchange worktable is a fantastic feature that allows us to maximize efficiency. The precision of the cuts is impressive, and it handles both sheets and pipes effortlessly.

Theron –

While the machine performs well, I found the initial setup a bit complicated. The exchange worktable is a great feature, but I wish the manual provided clearer instructions. Once we got it up and running, it has worked flawlessly.