Buyer Guide

Laser Cutting Wood

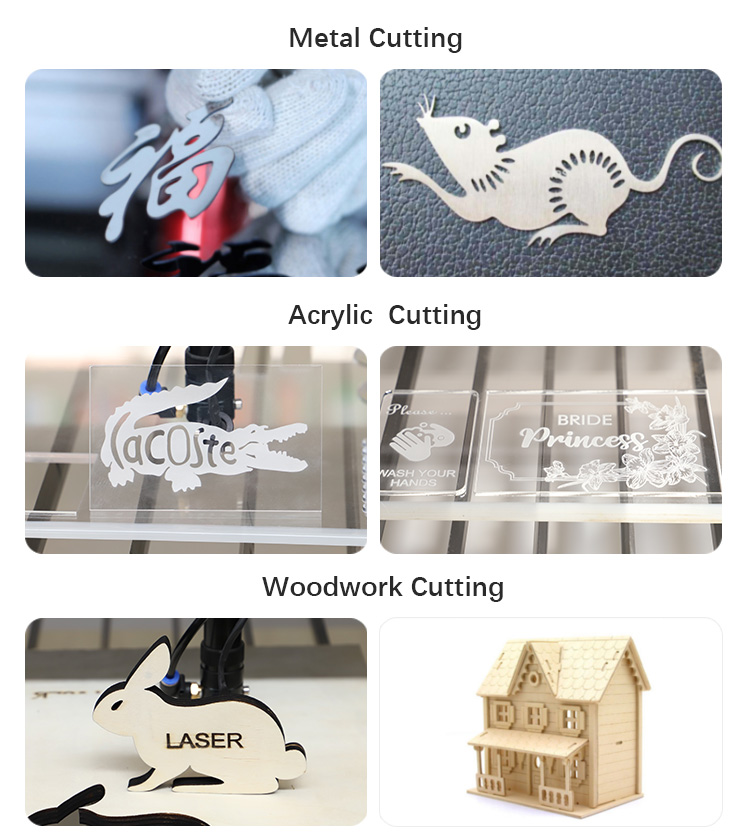

Laser cutting is an advanced technique widely used in various industries to cut and engrave materials with precision and intricate detail. One of the popular applications of laser cutting is in the realm of woodwork. This article provides a comprehensive overview of laser cutting wood, including the process, benefits, considerations, and potential applications.

Laser Cutting Wood Machine

- Laser Cutting Hardwood: laser cutting has good adaptability to hardwood. Common types of hardwood such as oak, walnut, and cherry wood can be accurately cut by CO2 laser cutting machines. CO2 laser cutting can provide fine cuts and engravings on these hardwoods.

- Laser Cutting Softwood: laser cutting is also suitable for softwood, such as pine, spruce, and cedar. Laser cutting can cut softwood quickly and can achieve detailed cuts.

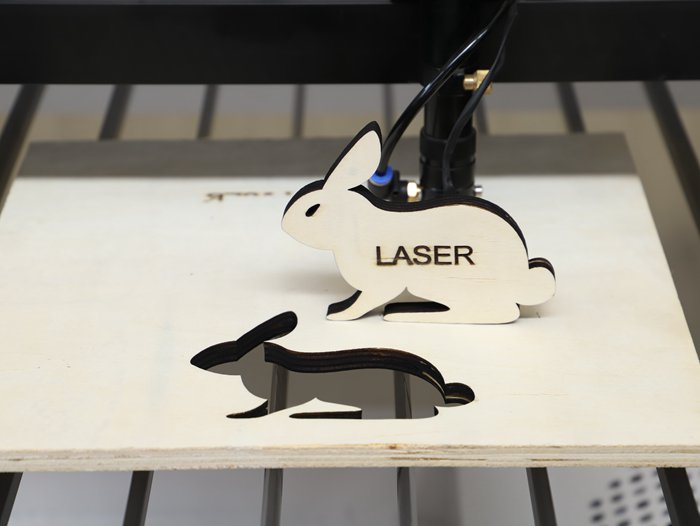

- Laser Cutting Plywood: laser cutting machines are efficient at cutting plywood, a material made from multiple layers of wood veneers glued together. Laser cutting can create complex designs and holes in plywood and is highly adaptable. Commonly used in furniture, construction, and craft manufacturing.

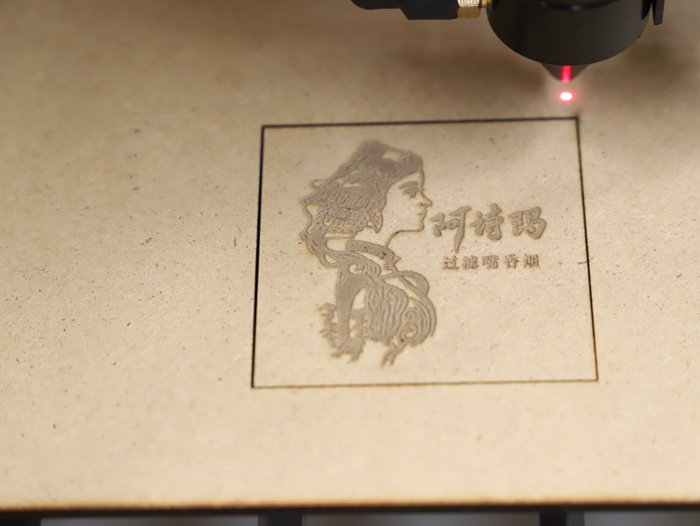

- Laser Cutting MDF: laser cutters are ideal for processing MDF, a high-density board made of wood fiber and synthetic resin. Laser cutting enables smooth cut edges on MDF without the need for further processing.

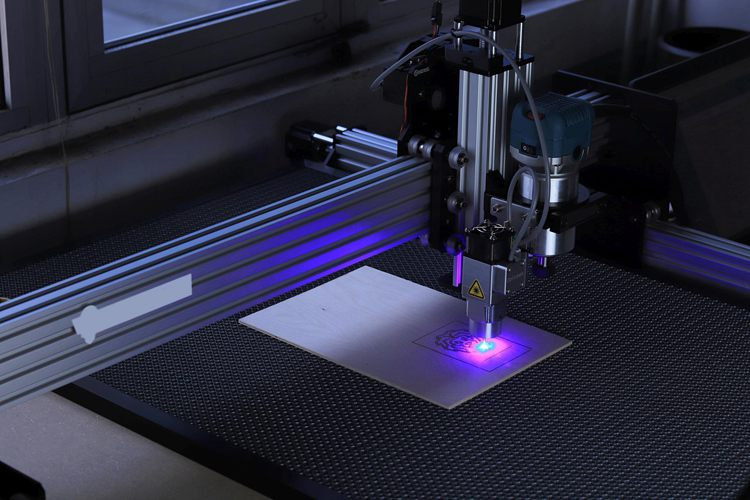

CO2 lasers are more powerful than diode lasers because their common optical power starts from 30-40W. You can find desktop CO2 lasers in the power range of 30-60W. It is more than enough to cut thick plywood or hardwood up to 20mm even more in only one pass.

In a CO2 laser cutting machine, there is a glass tube filled with a mixture of gasses, including nitrogen and CO2. When the electricity passes through this tube, it produces laser beams. Then, these beams are passed through mirrors and lenses to merge them at a spot. The laser tube has a lifespan of around 1,000 to 10,000 hours. After that, it is replaced by a new one.

A CO2 laser emits laser beams having a wavelength of 10,600nm, which can be easily absorbed by wood and a wide range of non-metals, including acrylic, leather, rubber, paper, cloth, cardboard, etc. It is more versatile than a diode laser. By using a CO2 laser, you can cut and engrave wood at an excellent speed. It does the job with perfection and offers optimal results. Secondly, these machines are equipped with some extraordinary features, such as cameras, auto-focus, batch-processing, etc.

Benefits of Laser Cutting Wood

Laser cutting wood offers several advantages over traditional cutting methods. Firstly, it enables intricate and precise cuts, allowing for the creation of complex designs and detailed patterns. The laser beam’s high accuracy and narrow kerf width contribute to the production of clean and sharp edges. Additionally, laser cutting is a non-contact process, minimizing the risk of material distortion or damage. Compared to conventional sawing or routing techniques, laser cutting produces minimal waste and reduces the need for secondary finishing processes. Another advantage is the versatility of laser cutting, as it can be used on various types of wood, including plywood, MDF (medium-density fiberboard), hardwood, and veneer.

Applications of Laser Cut Wood

Laser cut wood finds applications in various industries and sectors. In the field of woodworking, laser cutting is utilized to create decorative elements, intricate patterns, and detailed engravings on furniture, cabinetry, and architectural features. It is also commonly employed in crafting and hobbyist projects, such as model making, puzzle cutting, and personalized gifts. Laser cut wood is popular in the signage industry, enabling the production of custom signs, logos, and lettering. Furthermore, laser cutting can be used for prototyping and manufacturing purposes, allowing for rapid and precise production of wooden components or parts.

Laser Cut Wood Projects and Ideas

Laser Cut Wood Signs

Wooden signs are quite popular, and people like to have them as it also serves as a décor piece. The signs can be made in a wide variety of shapes and sizes. From plaques to office nameplates, anything can be made.

Laser Cut Wood Ornaments

Wooden ornaments are hot-selling items on special occasions, such as Christmas, weddings, Halloween, etc. You can make appealing ornaments using a laser cutting machine and even make them personalized for different people. There are hundreds of design ideas for different events and occasions. You can do vector cutting and engraving according to the design and personalization.

Laser Cut Wood Earrings

Wooden earrings are trending these days because people love to wear something unique and different. It is a decent idea that catches others’ attention. A laser cutting machine can make exceptional wooden earrings. There are tons of laser-cut files and designs available for earrings. You only need to import the design and cut it. After cutting, you only need to attach earring hooks and add colors to enhance the beauty.

Considerations and Safety Guidelines

When laser cutting wood, certain considerations and safety guidelines must be followed. Firstly, the type of wood being used should be compatible with laser cutting to avoid undesirable outcomes or the release of toxic fumes. Different types of wood have varying responses to laser cutting, such as variations in charring or scorching along the cut edges. Therefore, it is essential to conduct tests and experiments on scrap wood to determine the optimal laser settings for a particular wood type. Additionally, laser cutting wood generates heat, so proper ventilation and the use of protective equipment, such as safety glasses, are crucial to ensure operator safety. It is also important to consider the size and thickness of the wood, as these factors can influence the laser cutting machine’s capabilities and limitations.

How Laser Cutting Wood Works?

Cutting wood using a laser cutter is just like a hot knife through butter. It makes wood cutting easier than ever before. Most importantly, the finishing, accuracy, and quality of the cut are exceptional, which is impossible through other wood cutting tools.

A laser cutting machine contains a powerful laser source that emits laser beams. These beams are concentrated at a very small point by using a convex lens. Due to the merger of the laser beams at the point, the beams can produce intense heat energy after contact with any material that can absorb them. The temperature of the material increases quickly and converts the material into vapors. This is called sublimation, a process in which matter changes its state from solid to gas without going through the liquid phase.

In the case of wood, the reaction of the laser is a bit different. When the beams interact with wood, the wood starts to burn due to high temperature, removing the material from the surface, and if the power is high, the laser passes through the piece of wood and cuts it into pieces.

The burning of wood through a laser produces minimal ash, soot, and particles. The waste is much less than cutting the same wood using a saw. You get clean pieces with fine edges.

Wood laser cutting offers incredible speed and optimal accuracy. Depending on the power of a desktop laser cutter, the cutting speed can be 250mm/s or even more. The best part is that you only need to import the design to the laser cutter software, then the machine does everything on its own.

You can cut intricate designs, which is not possible by using a power tool. The accuracy of the laser machines is commendable. The laser spot is minimal and can engrave and cut materials with minimal Kerf width. You can cut identical designs as many times as you like and even have multiple passes on the same pattern without any errors or doubling.

Laser cutting wood offers a multitude of possibilities for creating intricate designs, precise cuts, and detailed engravings. By harnessing the power of a high-energy laser beam, woodworkers, designers, and manufacturers can achieve remarkable results. Though considerations and safety guidelines must be followed, the benefits of laser cutting wood, including its versatility, efficiency, and accuracy, make it an increasingly popular choice in various industries. Whether it’s for artistic expression, functional applications, or industrial production, laser cutting wood opens up a world of creative possibilities.

Pingback: Co2 Wood Laser Cutting Machine - iGOLDENLASER