Buyer Guide

Laser Engraving Glass Application Guide

Glass laser engraving has gained immense popularity in recent years due to its ability to create intricate designs on glass surfaces. Whether you’re an aspiring glass engraving artist or a business owner looking to offer laser engraving services, understanding the ins and outs of glass laser engraving is vital.

Do you own a glass engraving business? Are you a hobbyist glass engraver? Or maybe you’re just starting out on your DIY glass engraving journey. For each chapter in your DIY story, we have a user-friendly guide to answer all your questions on glass laser engraving and other laser applications. Open your imagination to endless glass engraving possibilities with our glass engraving machines. With IGOLDENLASER, you’ll be engraving glass in no time.

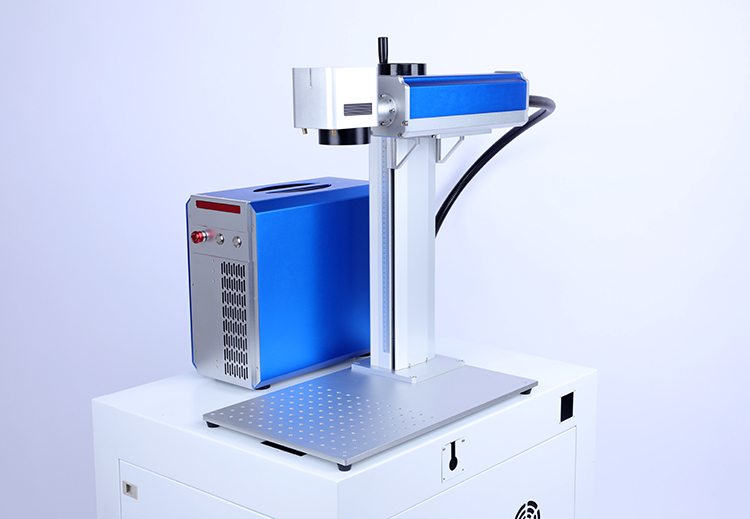

Glass Laser Engraver

Glass laser engraving has emerged as a game-changer in the world of glass art, enabling artists, designers, and businesses to elevate their creations with precision, creativity, and personalization. By harnessing the power of laser technology, glass engravers offer remarkable versatility, efficiency, and design possibilities that were previously unattainable through traditional methods. As this technology continues to advance, the potential for glass laser engraving in various industries is boundless. Whether you’re a glass artist seeking to push boundaries or a business looking to enhance branding and customization, investing in a glass laser engraver can open up a world of possibilities. Embrace the art of glass laser engraving and witness your visions come to life with unparalleled beauty and precision.

Glass etching with a laser is a non-contact process, which, unlike mechanical engraving, does not require workpieces to be clamped down or secured. The process itself does not produce stresses in the glass, which significantly reduces the risk of glass breakage in fragile, round glasses.

Understanding Glass Laser Engraving

- Explanation of the laser engraving process on glass.

- Key components and technology behind glass laser engravers.

- Different types of laser systems used in glass engraving, including CO2 and fiber lasers.

- Overview of the advantages of glass laser engraving over traditional methods.

- Importance of precision and control in achieving intricate designs on glass.

Which types of glass are best for engraving?

Decided that glass products are your cutting edge? Let’s find out which glass types work best with OMTech glass engraving machines.

Mirror glass

Window glass

Drinking glasses

Glass bottles

Vase glass

Cylindrical glass (eye glasses)

Cast glass

Pressed glass

Float glass

Sheet glass

Glass panels

Crystal glass

Applications of Glass Laser Engraving

- Glassware and Decorative Items: Customized glassware, wine glasses, vases, and decorative objects.

- Awards and Trophies: Personalized engravings for recognition and achievement awards.

- Architectural and Interior Design: Glass partitions, doors, windows, and decorative panels.

- Signage and Branding: Engraved glass signs, logos, and promotional items.

- Artistic Creations: Glass sculptures, art installations, and intricate patterns.

- Jewelry and Accessories: Customized glass pendants, bracelets, and ornaments.

Advantages and Benefits of Glass Laser Engraving

- Precision and Detail: Achieving intricate designs and fine details with laser accuracy.

- Versatility and Customization: Ability to engrave various glass types, sizes, and shapes.

- Time Efficiency: Rapid engraving process with minimal setup and preparation time.

- Durability and Longevity: Engravings that withstand wear, fading, and environmental factors.

- Personalization and Branding: Tailoring designs to individual preferences or corporate branding.

- Cost-Effectiveness: Elimination of consumables and reduced labor costs over traditional methods.

- Eco-Friendliness: Non-contact process with minimal waste and environmental impact.

Choosing the Right Glass Laser Engraver

- Factors to consider when selecting a glass laser engraving machine.

- Power and Speed: Determining the appropriate laser power and engraving speed.

- Software and Design Capabilities: Compatibility, ease of use, and design flexibility.

- Work Area and Size Limitations: Ensuring the machine accommodates the desired glass dimensions.

- Maintenance and Support: Evaluating after-sales service, training, and technical support.

- Budget Considerations: Balancing features, quality, and affordability.

Laser etching on glass

Glass objects can be decorated in different ways: by mechanical action, chemical etching, sandblasting and other methods. However, each of these options has its own disadvantages.

The main disadvantage is the relatively low accuracy of the pattern, as well as the requirement to rigidly fix the workpiece. Clamps can damage the glass surface and even ruin the product.

A laser machine for glass engraving helps to get only pluses and realize the most complex tasks. Today it is the most advanced technique that allows you to create durable images on glass with high accuracy.

The pattern is cut out with a focused laser beam: a stream of light beams of a specific wavelength. The size of the spot of light that forms on the surface of the workpiece is 0.01 millimeters. This makes it possible to draw the thinnest lines and make tiny dots, creating the desired pattern.

If you examine such a point under a microscope, you can see a small notch in the glass, around which there are microcracks. The cracks are only where the laser beam passes and cannot be seen with the naked eye. The rest of the glass removes smooth.

If you touch the engraving with your finger, you can feel the surface roughness. Under magnification, you can also see that the laser-treated glass takes on a slightly whitish hue. An important advantage of this method is the absence of stresses in the glass. The probability that it will crack and collapse in the process and after engraving is reduced to almost zero.

There are simply no impossible tasks for a laser glass engraving machine. The complexity of the image can be any: the laser is capable of conveying the smallest details. The effect is comparable to a good photo; the accuracy and detail of the picture is as high.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.