Buyer Guide

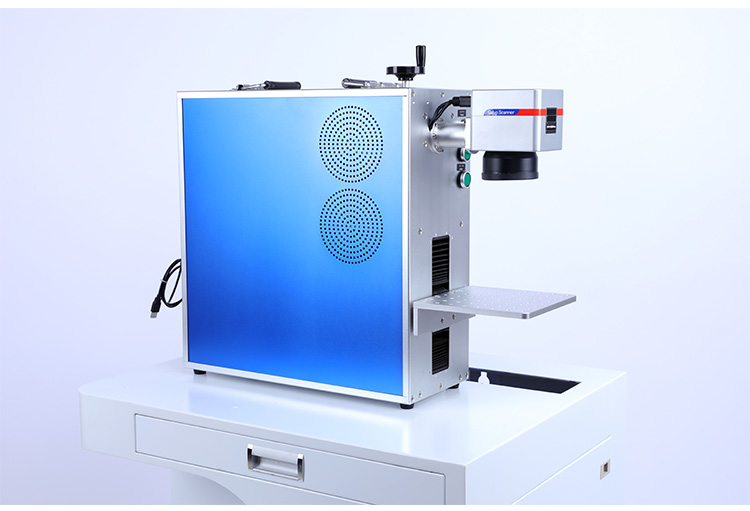

Laser Engraving Machine Metal 20w 30w 50w

Laser engraving machine metal is the process of permanently marking a surface using a focused beam of light. It can be performed using different types of lasers, including fiber lasers, CO2 lasers, pulsed lasers, and continuous lasers. The three most common laser marking applications are:

As we all know, each product in the market after the fixed on the product to the user to show the factory identification, brand differentiation, product parameters and other information signs. It is also known as the sign, mainly used to identify the manufacturer’s information and product ratings under the conditions of some basic technical data for the correct use of the user without damaging the laser equipment. Nameplate of the production materials have metal and non-metallic categories, metal types have zinc alloy, copper, iron, aluminum, stainless steel, and so on, aluminum materials in the actual application of more, this is because the aluminum material processing of the sign effect is relatively beautiful, and material wear-resistant, not easy to rust.

The only valid “identity coding” as a product is self-evident, such as the marking of product models, specifications, production batches, production dates, and so on, especially in large-scale production, where thousands of different metal nameplates are numbered. How can we accomplish this efficiently?

It has to be said that this is no longer a problem for fiber laser engraver. Traditional marking method of marking the surface is more rough, and time-consuming, and the use of laser marking machine can avoid this kind of malpractice, laser marking good contrast, smooth surface, high precision, fast, so that the product looks more grade.

Laser engraving machine metal features:

High quality fiber generator, good quality spot, optical power density uniform, stable output optical power, meets the application demand of mainstream market;

Han’s Yueming self-developed digital high-speed galvanometer scanner, small size, high speed and excellent stability; the performance reaches the international advanced level;

Powerful control system, optimizes the processing data according to various application, supports multi language switch, and up to 256 color layer management functions, meets the application requirements of most industries;

Die-casting mold manufacturing lifting frame, stable structure, built-in linear guide, simple design.

The Benefits of laser engraving machine metal:

Laser marking is a high-speed, non-contact process that uses a focused laser source to slowly heat or quickly vaporize materials. Our systems can use vector drawings or raster images to mark almost any pattern onto your parts including text, custom graphics, barcodes and 2D data matrices.

Unlike traditional marking processes, laser marking doesn’t require masks, inks or custom machining bits—reducing operating costs and changeover time between parts and designs.

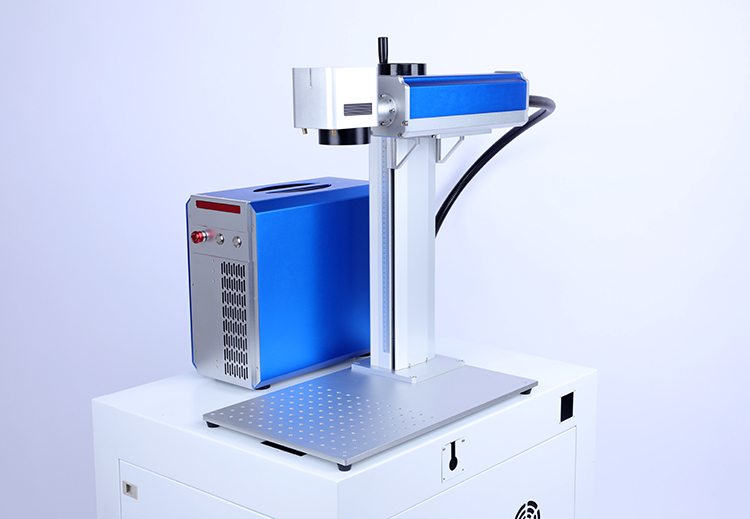

Laser Engraver For Stainless Steel

Laser Engraver For Stainless Steel using scanning method marking, the laser beam incident to the two mirrors, the use of computer-controlled scanning motor to drive mirrors along the x, Y axis, laser beam focusing on the work of the marked workpiece, thus forming a mark of laser marks. Laser marking can play a variety of text, symbols and patterns, character size can be from millimeters to micron level, which has a special meaning for the product security.Laser Marking Machine

Features of Laser Engraver For Stainless Steel :

1. Laser marking machine on promotion, high cost performance.

2. Fiber lasergenerator ,low consumption, easy for maintain.

3. Compact design, 760mm×610mm×1494mm

4. Optional lens for different marking area

Laser Metal Engraving Machine Applications

Laser marking can mark a variety of materials such as steel, aluminum, stainless steel, polymers, and rubber.

It is often used to identify parts and products with 2D barcodes (data matrix codes or QR codes), alphanumerical serial

.Laser marking machine is mainly for marking on Jewelry,gold, Curve metal,silver, titanium, copper, alloy, aluminum, steel, manganese steel, magnesium, zinc, stainless steel, carbon steel / mild steel, all kinds of alloy steel, electrolytic plate, brass plate, galvanized sheet , Aluminum, all kinds of alloy plates, all kinds of sheet metal, rare metals, coated metal, anodized aluminum and other special surface treatment, electroplating the surface of the aluminum-magnesium alloy surface oxygen decomposition.

Metals (including rare metals), engineering plastics, electroplating materials, coating materials,coating materials, plastics, rubber, epoxy resin, ceramic, plastic, ABS, PVC, PES, steel, titanium, copper and other materials.appliances, communication products, sanitary ware, tools,accessories, knives, eyeglasses and clocks, jewelry, auto parts, luggage buckle, cooking utensils,stainless steel products and other industries.numbers, VIN numbers, and logos.

Conclusion

Metal engraving offers more possibilities for metal processing. Metal is a versatile engineering material valued for its strength, durability, and conductivity. Common industrial metals include steel, aluminum, titanium, and alloys like stainless steel. Metals can be cut, welded, formed, and joined in various ways. Besides, laser engraving is an advanced processing method. The focused high-energy laser beam can quickly and precisely melt or vaporize metal material along its path of the beam.

Meanwhile, it can also mark and etch permanent graphics and text onto metal surfaces for identification or decoration. Lasers provide contactless processing and allow for automation in metal fabrication. Overall, laser technology enables high precision and efficiency in metal engraving and marking applications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.