Buyer Guide

Laser Engraving Materials: Uncover the Best Choices

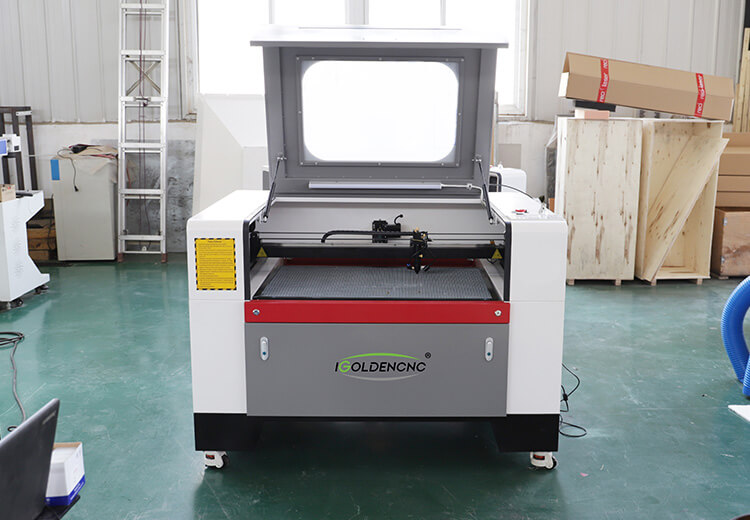

CO2 laser cutters have become the most affordable and best-value cutting tools in the recent years, and can be your good partner to bring your creations, ideas and designs to life with personalized gifts, crafts, arts, decors, signs and logos.

CO2 laser is a pulsed wave beam in which carbon dioxide gas obtains continuous wave or high output area in the infrared of the medium. The wavelength is 10.6μm. It is a light source used for rapid prototyping. High-power lasers are used for cutting and drilling. The medium power output is used for engraving. Since the output wavelength is easily absorbed by water, it is also widely used in medical treatment.

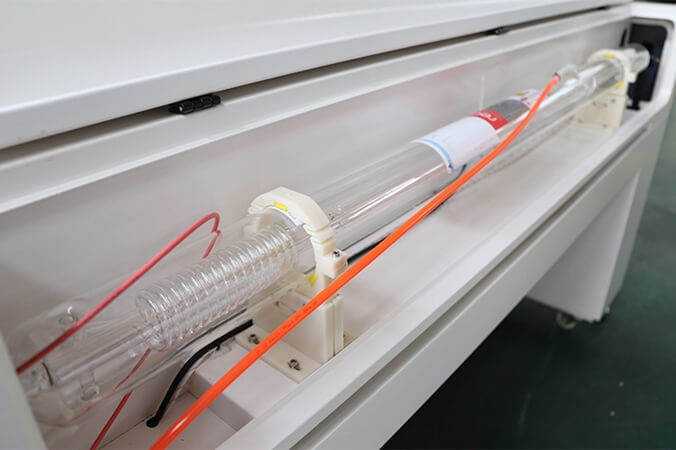

A CO2 laser generator is a gas laser generator with CO2 gas as the working material. The discharge tube is usually made of glass or quartz material, filled with CO2 gas and other auxiliary gases (mainly helium and nitrogen, and usually a small amount of hydrogen or xenon). The electrode is generally a hollow nickel cylinder and a resonant cavity. One end is a gold-plated total reflection mirror, and the other end is a partial reflection mirror polished with germanium or gallium arsenide. When a high voltage (usually DC or low-frequency AC) is applied to the electrode, a glow discharge is generated in the discharge tube, and there is a laser output at one end of the germanium mirror, and its wavelength is in the mid-infrared band near 10.6 microns.

Carbon dioxide laser generators are usually made of hard glass, and generally adopt a layered sleeve structure. The innermost layer is the discharge tube, the second layer is the water-cooled casing, and the outermost layer is the gas storage tube. The diameter of the discharge tube of the carbon dioxide laser generator is larger than that of the He-Ne laser tube. Generally speaking, the thickness of the discharge tube has no effect on the output power, mainly considering the diffraction effect caused by the size of the light spot, which should be determined according to the tube length. The longer tube is thicker, and the shorter tube is thinner. The length of the discharge tube is proportional to the output power. Within a certain length range, the output power per meter of discharge tube length increases with the total length. The purpose of adding a water cooling jacket is to cool the working gas and stabilize the output power. The discharge tube is connected to the gas storage tube at both ends, that is, one end of the gas storage tube has a small hole communicating with the discharge tube, and the other end communicates with the discharge tube through the spiral return tube, so that the gas can circulate in the discharge tube and the gas storage tube flow, the gas in the discharge tube is exchanged at any time.

Laser Engraving Materials

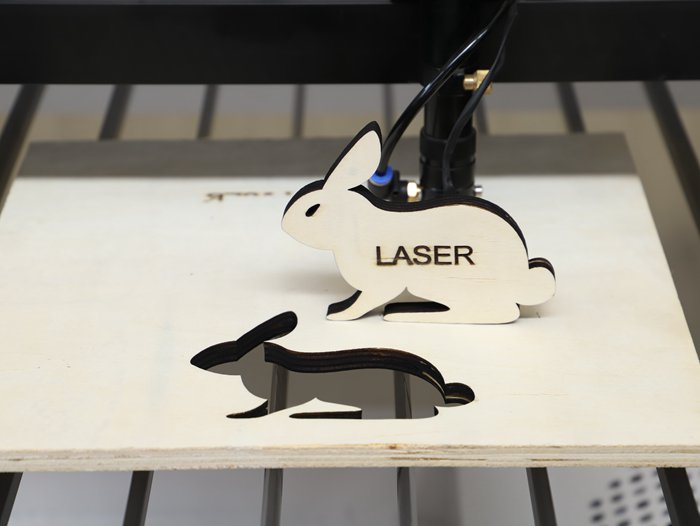

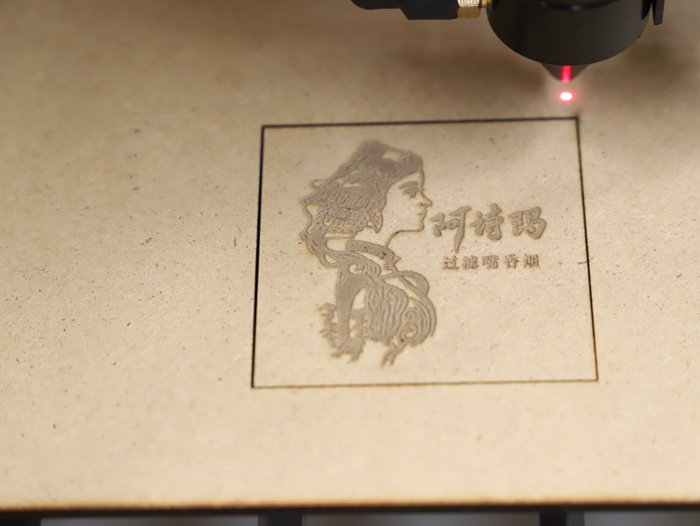

Wood and Plywood: CO2 lasers are excellent for engraving wood and plywood. They can create intricate designs, patterns, and text on wooden surfaces. Different types of wood, such as hardwood, softwood, and plywood, can be engraved with varying results.

Acrylic: Acrylic is a popular material for laser engraving due to its clarity and versatility. CO2 lasers can engrave acrylic to create precise and detailed designs, logos, or text. The laser can also create a frosted or deep-etched effect on the surface of the acrylic.

Coated Metals: CO2 lasers can mark and engrave certain coated metals, like anodized aluminum or painted metal surfaces.

Certain Plastics: CO2 lasers can engrave various types of plastics, including ABS, PVC, polycarbonate, and more. The laser beam interacts with the plastic surface, causing it to melt or vaporize, resulting in engraved markings. CO2 lasers can produce precise and detailed engravings on plastics, making them suitable for personalized items, signage, or product branding.

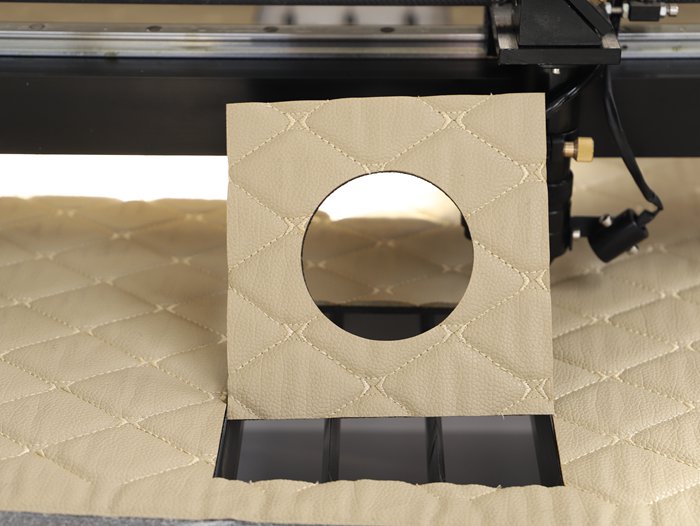

Leather: CO2 lasers can engrave leather with precision, allowing for the creation of intricate patterns, logos, or personalized designs. The laser can produce varying depths of engraving, resulting in different textures on the leather surface.

Rubber: Some rubber materials can be engraved with a CO2 laser for creating stamps or other custom products.

Glass: While CO2 lasers are primarily used for engraving, they can also mark or etch certain types of glass surfaces. The laser beam removes a thin layer of the glass, creating a frosted or textured effect. It’s important to use specially designed glass for laser engraving to avoid cracking or shattering.

Paper and Cardboard: CO2 lasers can engrave paper and cardboard materials, making them suitable for creating intricate designs, invitations, greeting cards, or packaging prototypes. The laser can produce fine details and intricate patterns on these materials.

Fabric and Textiles: CO2 lasers can engrave certain types of fabrics and textiles, such as cotton, linen, and polyester. They can create unique patterns, designs, or even personalized text on fabrics. It’s important to test the specific fabric to ensure it doesn’t burn or ignite during the engraving process.

Stone and Marble: CO2 lasers can also engrave stone and marble surfaces. The laser can create detailed designs, artwork, or text on these materials. The effect of the engraving will depend on the type of stone and its composition.

Ceramics: Certain types of ceramics can be engraved with a CO2 laser, though the results may vary. The laser can remove glaze or create surface patterns.

Organic Materials: CO2 lasers can engrave certain organic materials like cork, leatherette, and some types of wood veneer. These materials can produce unique and decorative engravings with interesting textures and patterns.

It’s important to note that while CO2 lasers can engrave a wide range of materials, the results may vary depending on factors such as the material composition, thickness, surface finish, and the specific laser machine’s power and settings. It’s always recommended to conduct material tests to determine the most suitable parameters for achieving the desired engraving results.

Steps Involved in Co2 Laser Engraving Machine

- Design Creation: Begin by creating a digital design or artwork using graphic design software. Common formats include vector graphics, as they allow for precise control of the laser.

- Material Preparation: Select the material to be engraved. CO2 lasers are versatile and can work with various materials, including wood, acrylic, leather, paper, and more. Prepare the material by ensuring it is clean and properly positioned within the laser engraving machine.

- Machine Setup: Set up the CO2 laser engraving machine, ensuring that it is calibrated and focused correctly. Proper calibration is essential for achieving accurate and consistent results.

- Import Design into Software: Import the digital design into the software that controls the laser engraving machine. This software allows you to adjust settings such as power, speed, and resolution.

- Adjust Settings: Configure the laser settings based on the material you are engraving. This includes determining the appropriate laser power, engraving speed, and other parameters.

- Test Run: Before engraving the final product, perform a test run on a scrap piece of the same material to ensure that the settings are optimized and the design looks as expected.

- Engraving Process: Start the engraving process by activating the CO2 laser. The laser beam will follow the path specified by the digital design, removing or altering material as it moves across the surface.

- Quality Inspection: After the engraving is complete, inspect the quality of the finished product. Check for any inconsistencies, errors, or undesired effects.

- Post-Processing (Optional): Depending on the material and desired appearance, you may choose to perform additional post-processing steps, such as cleaning, applying finishes, or adding color to the engraved areas.

- Safety Precautions: Always follow safety guidelines when working with CO2 lasers. Use appropriate protective gear, ensure proper ventilation, and adhere to the machine’s safety features.

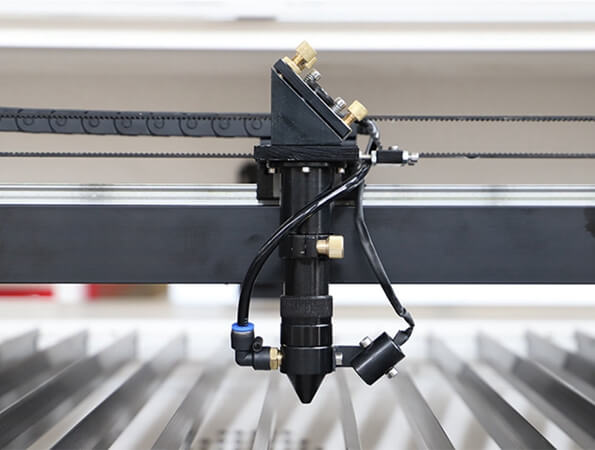

A CO2 laser cutting machine is a professional automatic engraving and cutting system using a 1064μm CO2 laser beam to etch and cut wood, MDF, plywood, paper, leather, fabric, textile, resin, plastic, acrylic, rubber, crystal, glass, ceramics, stone, and more non-metallic materials. It relies on the power to drive the carbon dioxide gas laser tube to emit beam, with reflectors, the light beam is transmitted to the cutting head, and then the focusing mirror converges the beam on a point, and this point can reach a very high temperature, thus the excess material is instantly sublimated into gas, which is sucked away by the exhaust fan, so as to create a cut. CO2 lasers are used to engrave patterns and cut shapes & contours in clothing, fashion, garment, shoes, bags, toys, embroidery, electronic appliances, molds, models, arts, crafts, advertising, decorations, packaging, and printing.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.