No products in the cart.

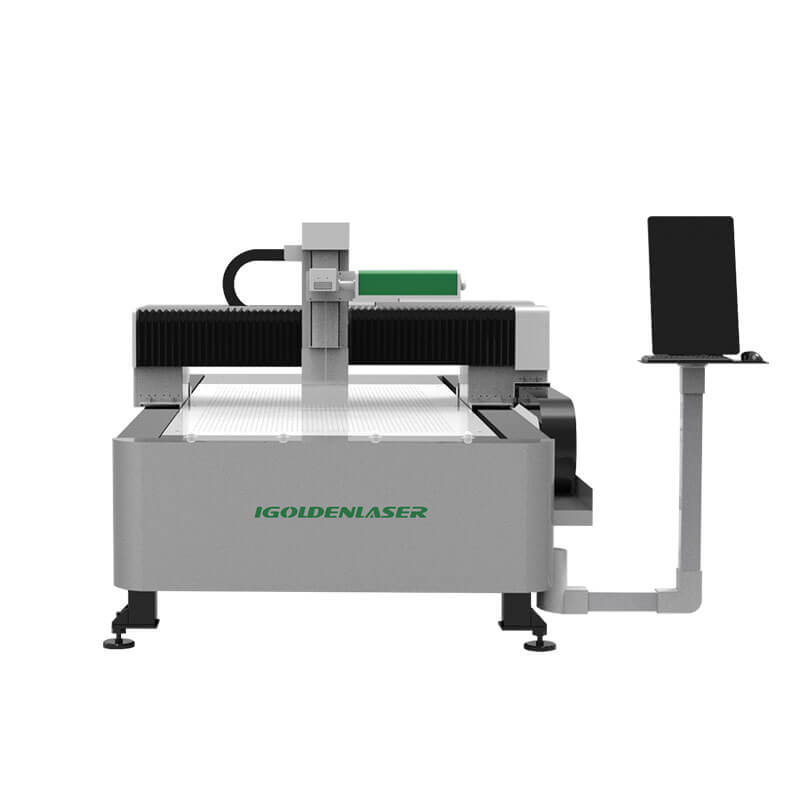

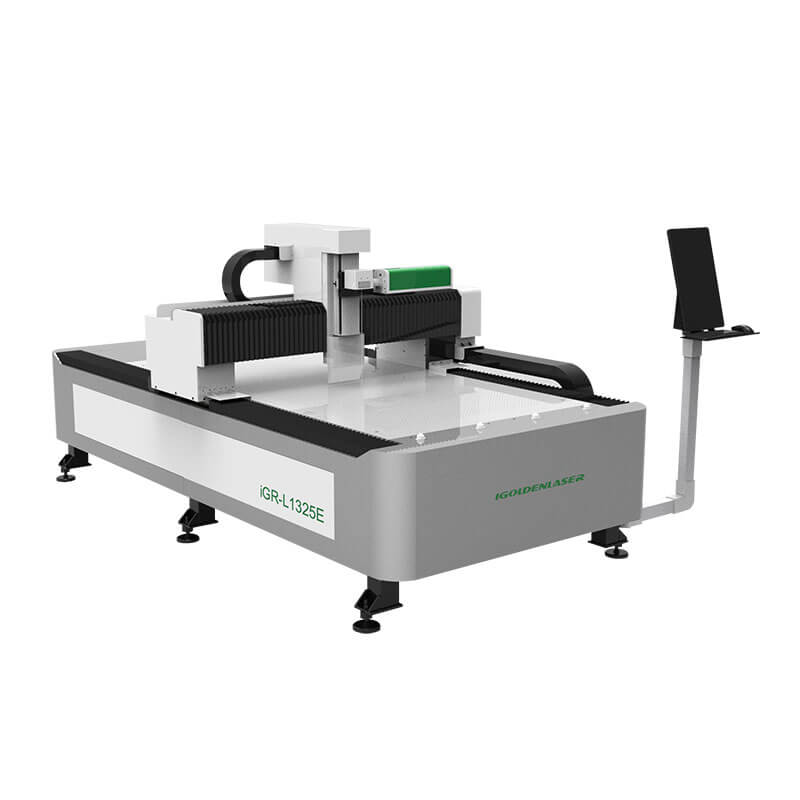

iGR-L(E)

Best Laser Etching Machine for Glass and Metal

Laser etching machines employ various marking techniques, including surface ablation, surface annealing, and color change. Surface ablation removes material to create depth, while surface annealing heats the material to create a contrasting mark without removing material. Color change techniques rely on chemical reactions within the material to produce visible marks.

Laser etching machines are controlled through computer software. The operator can input the design or text that needs to be etched, and the machine follows the specified instructions.Laser etching machines can work on a wide range of materials, including metals (such as stainless steel, aluminum, brass), plastics, wood, glass, leather, acrylic, and more. The laser energy can be adjusted to match the material, allowing for precise and clean etching.

Reviews

There are no reviews yet.