Laser Knowledge

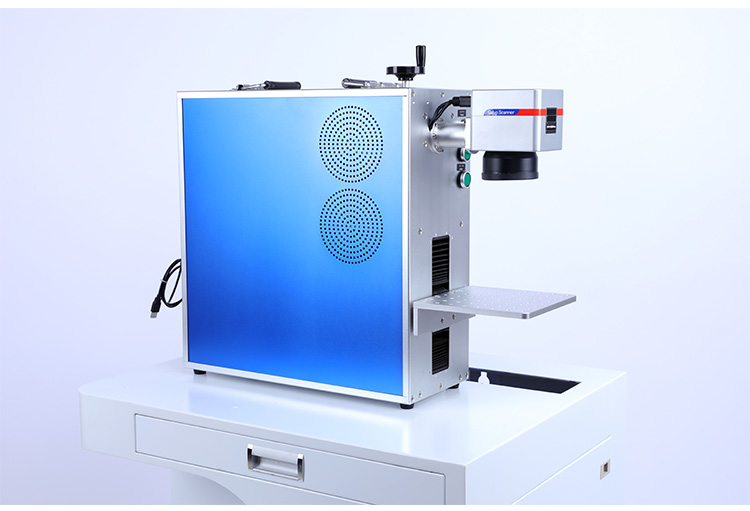

Laser etching machine user guide

Laser etching machines are also referred to as laser engraving machines in the laser machine industry. Whether in the machine structure, or on the principle of processing, the laser etching machine is very similar to the laser engraving machine, and in processing materials, applications, these two machines are also very similar. The laser machine can process metal and various non-metallic materials. They are more popular among the products that require fine and high precision products.

What is laser etching machine?

Laser etching machine refers to an etching material surface using a high energy laser beam. The main components of the laser etching machine include optical path systems, control systems, positioning systems, stabilizing systems, mechanical motion systems, adsorption purification systems, and other major components. The processing technology of laser etching machines mainly includes cutting, engraving, etching, drilling, etc. It is usually used for touch screens, solar photovoltaic industries and military industries with high machining precision.

Laser etching machine for processing materials

Materials can be processed by laser etching machines include common metals, alloys, rare metals and non-metallic materials. Ordinary metal materials include carbon steel, stainless steel, galvanized plate, and the like. Alloy metal includes all metals such as iron, copper, aluminum, magnesium and zinc. Rare metal includes gold, silver, titanium and other materials. In addition, it can handle some metal oxides and some special surface treatments, including aluminum anode oxidation, electroplating surface, and the like. Non-metallic materials include ABS materials, inks, epoxy resins, and the like.

What can laser etching machines?

Laser etching machines can be widely used in hardware tools, automotive parts, sanitary cleansing, medical equipment, communication equipment, glasses, watches and other industries. Laser etching machine is also very popular in instruments, bamboo, clothing, food, beverage, packaging and crafts.

In addition, the application of laser etching machines also relates to electronic components, integrated circuits, electrical, communication products, logos, sanitary cleans, hardware, tool accessories, precision equipment, jewels, suitcases, tools, locks, cookware, PVC pipes and others industry.

Laser etching machine processing characteristics

The processing advantages of laser etching machine are similar to other laser machines. It is well known that the laser machine uses a non-contact treatment. It has the advantages of high flexibility, fast processing speed, no noise, and small thermal impact area. Through the above advantages, it can achieve good drilling, engraving, etching and cutting effects. Especially when it interacts with some materials, such as polyamides, the processing effect is better. Since this treatment is a cold processing of photochemical effects. This processing method can achieve a non-carbine treatment effect.

Difference between laser etching machine and laser engraving machine

1. Processing principles are different. The laser engraving machine uses the burning of the laser beam to evaporate a portion of the surface of the medium to achieve the processing effect. The oxidation reaction between the laser etched machine uses the material dissolution.

2. Processing effect is different. For treatment techniques, laser engraving is mainly very shallowed in many metal media and certain density materials. Depth engraving has not been implemented. The depth of the etching machine can basically be as needed. And combined with the coating process, it can also achieve color and multi-color modifications.

3. The scope of application is different. The laser engraving machine has a broader application range. It can engrave and mark most of the materials, metal materials and non-metallic materials. However, laser etching machines are mainly working metal materials.

4. The machining process is different. The laser engraving process is simple and the processing steps are processed. The processing of laser etching processes is complicated, and there is more detail to pay attention to the details.

5. Different production efficiency. The laser engraving machine is suitable for small batch engraving or tags. Laser etching machine is more suitable for large manufacturers, suitable for DA.

6. Accuracy is different. In general, the accuracy of the etching process is higher, combined with the photoresist process, and the accuracy can reach 0.01 mm.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.