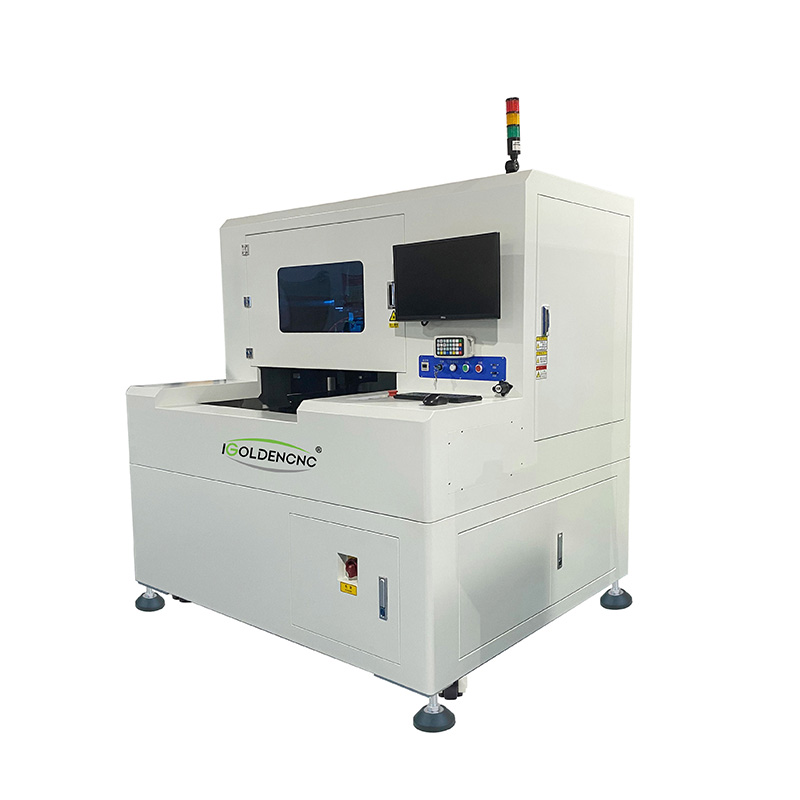

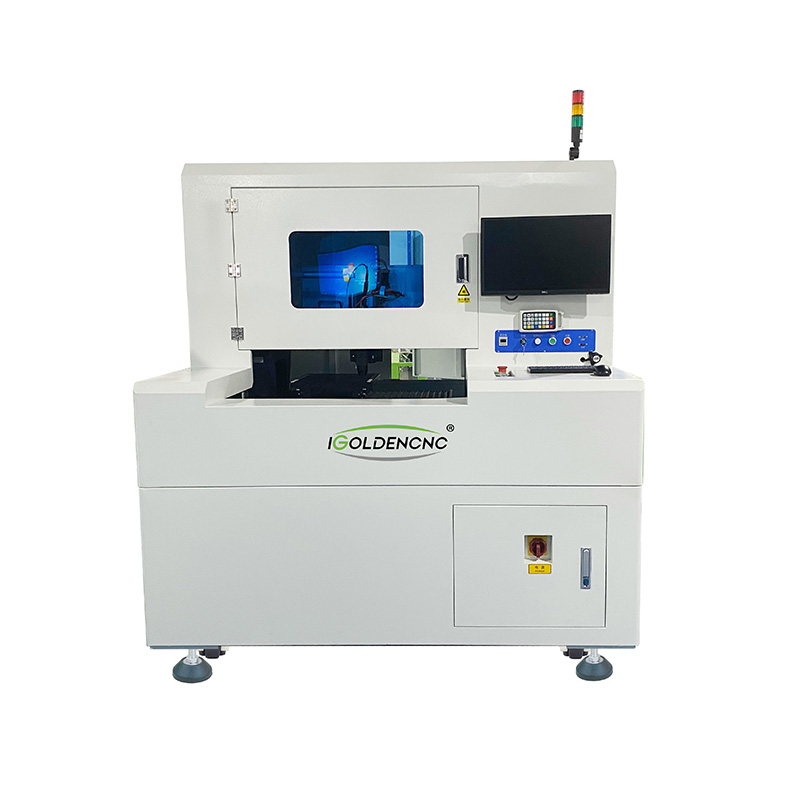

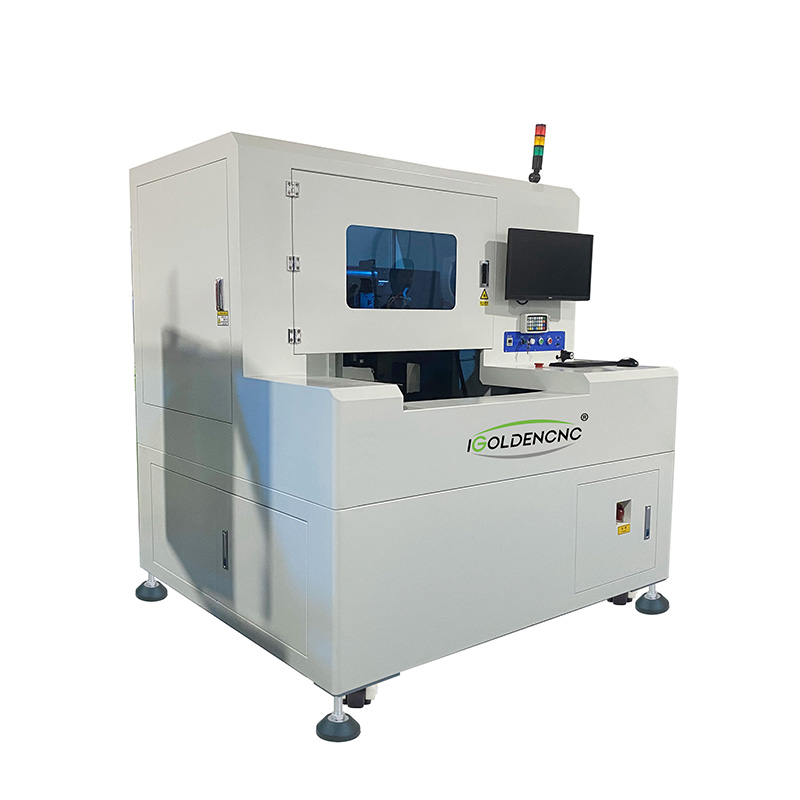

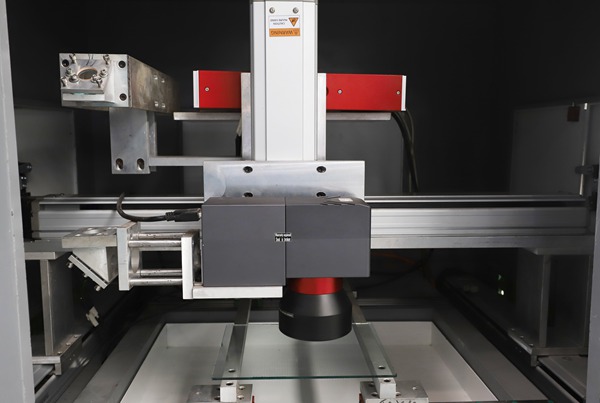

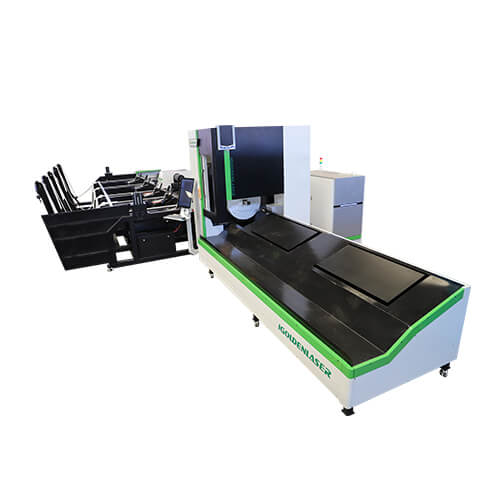

iGR-GC

Enclosed Fiber Laser Cutting Machine

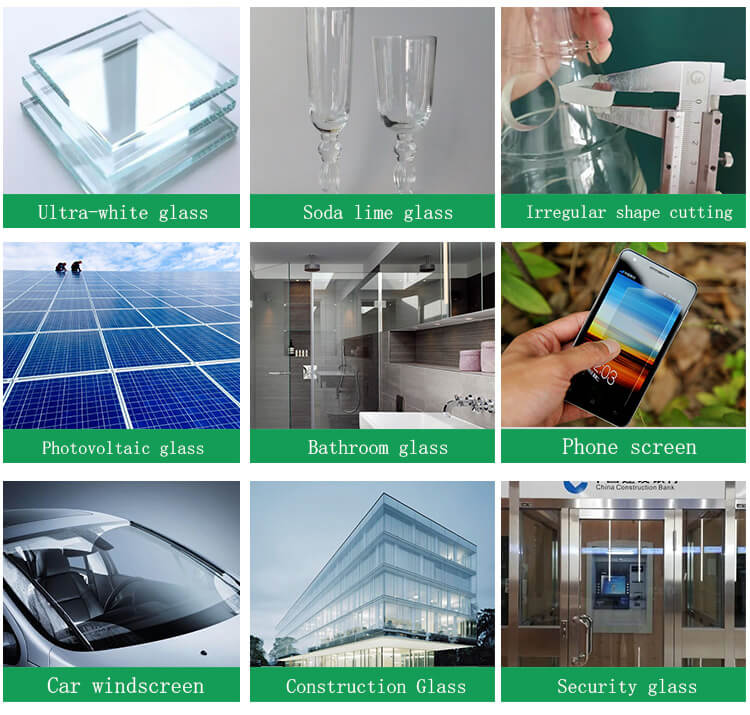

The equipment uses high-energy and high-precision lasers to cut/drill glass materials. High-definition image alignment and professional customized operation software control system make the production efficiency higher, the repeated positioning more accurate, and the operation easier. The equipment has been widely used in instrumentation glass/photovoltaic glass/mobile phone glass/medical instrument/vehicle display/panel display glass and other industries.

High-definition image alignment and professional customized operation software control system make the production efficiency higher, the repeated positioning more accurate, and the operation easier. The equipment has been widely used in instrumentation glass/photovoltaic glass/mobile phone glass/medical instrument/vehicle display/panel display glass and other industries.

Jack –

Investing in this laser glass cutting machine was a smart decision. It has elevated the quality of our products and improved our overall production efficiency.

Weekly –

The machine’s safety features and reliable performance give us confidence in our operations. It’s a top-notch piece of equipment for any glass-cutting needs.