Buyer Guide

Laser Paint and Rust Removal Tool

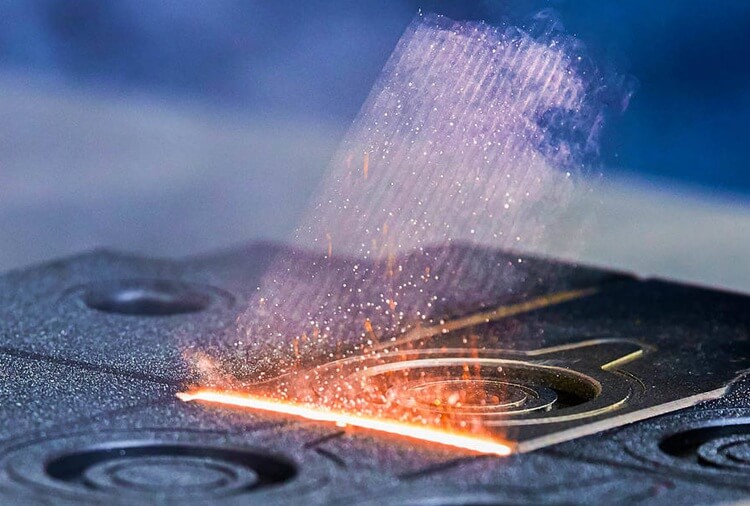

Laser paint and rust removal tools use laser technology to eliminate paint, rust, and other unwanted coatings from surfaces. These tools use high-intensity laser beams to heat and vaporize the targeted paint or rust, causing it to separate from the underlying material.These tools are efficient and precise, making them popular in various industries such as automotive, manufacturing, and restoration.

Laser Paint and Rust Removal Tool

iGCL series paint laser remover and cleaner are equipped with 1000W, 1500W, 2000W, and 3000W high power continuous wave fiber lasers and a high-speed cleaning head. It is the ideal choice for cleaning and removing rust, paint, oil, coating, film, and other contaminants from the surface of both metal and non-metal materials. With a handheld and portable design, it becomes more and more popular in many industrial, military, and aerospace fields.

How Laser Paint and Rust Removal Tool Works

Laser Technology: The tool emits a high-intensity laser beam. The laser energy is absorbed by the paint or rust on the surface.

Material Interaction: The absorbed energy causes the paint or rust to heat up rapidly. This rapid heating results in the breakdown of the molecular structure of the unwanted material.

Vaporization and Removal: The material is converted into vapor or small particles. The vaporized material or particles are then removed from the surface.

Laser Paint and Rust Removal Tool Key Features

Precision: Laser systems offer high precision, allowing for selective removal without damaging the underlying substrate. Versatility: Suitable for various materials, including metal, wood, and certain plastics.

Efficiency: Laser removal is often faster than traditional methods, increasing efficiency.

Environmental Benefits: Compared to some traditional methods like sandblasting or chemical stripping, laser removal can be more environmentally friendly as it produces fewer waste byproducts.

Safety: Laser systems are designed with safety features to protect the operator and surrounding environment.

Laser paint and rust removal tools offer several advantages over traditional methods. They are non-abrasive, which means they are less likely to damage the underlying material. They are also more precise, allowing for targeted removal without affecting nearby areas. Additionally, laser tools can be used on a variety of surfaces, including metal, wood, concrete, and more.

It’s worth noting that laser paint and rust removal tools can vary in terms of power, capabilities, and features. If you are considering using such a tool, it’s important to choose a reputable manufacturer and follow the instructions and safety guidelines provided by the manufacturer to ensure proper and safe operation.

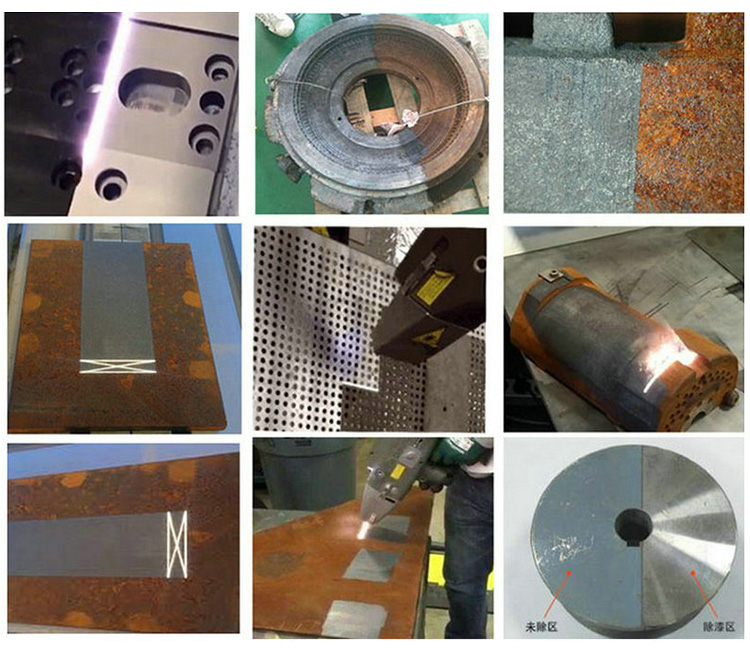

Laser Paint and Rust Remover Applications:

Laser cleaning machines are widely used in various industries for tasks such as surface preparation, restoration, and maintenance. When considering such a machine, it’s important to match its specifications with the specific cleaning requirements of the project, taking into account the material and type of contaminants to be removed.

Automotive Industry: Used for paint removal from cars and other vehicles.

Manufacturing: Effective in removing coatings from metal parts during manufacturing processes.

Restoration and Conservation: Applied in the restoration of historical artifacts and architectural structures.

Ship Maintenance: Used for rust and paint removal in marine applications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.