No products in the cart.

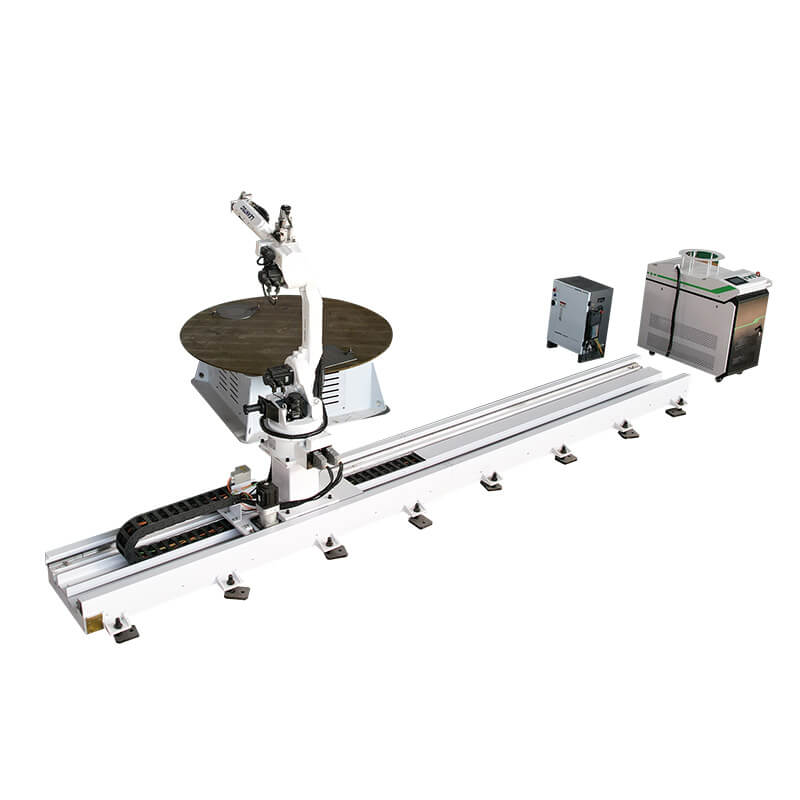

iGWL-RW series

Robot Laser Welding Machine

Robot laser welding machine is a type of industrial equipment that combines robotic technology with laser welding capabilities. Laser welding is a welding process that uses a laser beam to melt and join metals together. When integrated with a robotic system, it allows for precision and automation in the welding process.

Robot laser welding systems provide high precision and accuracy in the welding process. The focused laser beam allows for fine control over the welding parameters, resulting in clean and precise welds.

Automation with robots can improve workplace safety by reducing the need for human operators to be in close proximity to the welding process. This can be especially beneficial in hazardous environments.Robot laser welding machines can be equipped with sensors and vision systems for quality control purposes. These systems can monitor the welding process in real-time, ensuring that the welds meet the specified standards.

Optional laser power 1500W-3000W; support customization.

igolden –

correct welding can be repeated

Chloe –

The laser robotic welding machine has dramatically improved our production line! The precision of the welds is outstanding, and the speed is impressive. It has streamlined our processes and reduced labor costs significantly. Highly recommend!