Laser Knowledge

The Cost Benefits of Laser Welding Medical Device Manufacturing

As the medical device industry continues to innovate and advance, manufacturers are constantly seeking new technologies and processes that can improve product quality, increase efficiency, and reduce overall costs. One area that has seen significant growth and adoption in recent years is the use of laser welding for assembling medical devices.

Laser welding offers a range of advantages over traditional joining methods, such as superior weld quality, higher precision, and enhanced repeatability. These benefits are particularly valuable in the production of sensitive, complex, and miniaturized medical devices. However, the upfront investment in laser welding equipment can be a major consideration for many manufacturers.

In this article, we’ll explore the cost factors associated with implementing laser welding in medical device production and discuss strategies to maximize the return on this investment.

The Advantages of Laser Welding for Medical Devices

Laser welding has become an increasingly attractive technology for medical device manufacturers due to the unique advantages it offers:

Precision and Repeatability

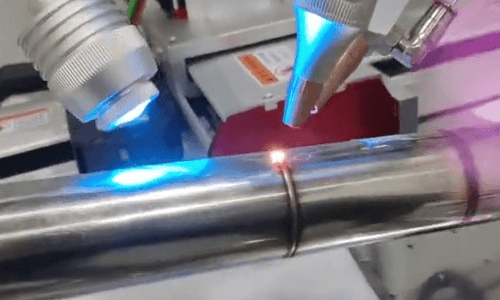

Laser welding can produce extremely precise, high-quality welds with minimal distortion, making it ideal for the assembly of intricate medical devices with tight tolerances.

Minimal Heat Affected Zone

The localized heating of laser welding results in a smaller heat-affected zone, reducing the risk of heat-related damage to delicate components. Automation and Throughput: Laser welding can be easily integrated into automated production lines, improving throughput and reducing labor costs.

Versatility

Laser welding can be used to join a wide range of materials commonly used in medical devices, including stainless steel, titanium, and nitinol.

Cleanliness

Laser welding is a clean, non-contact process that minimizes the risk of contamination, an essential requirement for medical device manufacturing. Traceability: Advanced laser welding systems can incorporate in-process monitoring and data logging, enabling improved quality control and traceability.

These advantages have made laser welding an increasingly attractive option for medical device manufacturers, from implantable devices to surgical instruments and drug delivery systems.

The Long-Term Benefits of Laser Welding in Medical Device Manufacturing

While the upfront cost of a laser welding system may be a significant consideration, the long-term benefits it can provide to medical device manufacturers make it a valuable investment. These benefits include:

Key Advantages of Laser Welding

Low Heat Input – Due to the precision of the welding laser, weld energy is delivered with exceptional control and only where it’s needed. Total heat input is so low that laser welding next to thermally sensitive components such as glass-to-metal seals, electronic circuitry, O-rings and plastic components is not only possible, but a common practice.

Clean Welds – In addition to the aesthetic benefits, clean laser welds yield significant safety and usability benefits. Clean welds allow for products that are easier to sterilize or fit into other assemblies without weld seam interference.

Strong Welds – Lasers provide high strength with a minimum number of welds, yielding time savings and increased reliability.

Hermetic Welds – Unlike soldering or brazing, lasers can provide flawless hermetic welds essential to many medical applications.

Excellent Repeatability – The laser’s output is incredibly stable, and with no electrodes to wear, bend or vaporize (and contaminate the weld nugget), weld repeatability is unmatched.

Easy Welding of Conductors – Materials such as Platinum, Gold, Copper alloys, Stainless Steel, Nitinol, Titanium, MP35N, Elgiloy and dissimilar metals can easily be welded with excellent results and repeatability.

Clean Process – Unlike soldering or brazing, lasers don’t need fluxes or solvents, keeping the work environment cleaner and safer.

When evaluated holistically, the long-term benefits of laser welding can far outweigh the initial investment, making it a strategic and valuable asset for medical device manufacturers seeking to optimize their production processes, improve product quality, and drive sustainable growth.

Laser welding machines have become indispensable tools in the medical device manufacturing industry, offering unparalleled precision, reliability, and versatility in joining critical components. From surgical instruments to implants, catheters to microfluidic devices, laser welding technology plays a vital role in advancing healthcare technology and improving patient care.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.