Buyer Guide

Laser Welding Solutions and Choose !

Laser Welding Machines|Handheld Laser Welder Manufacturer

Laser welding is an ideal solution for welding metal materials like aluminum, stainless steel, copper, and various alloys. IGOLDEN’s laser welders, known for their cost-effectiveness, easy-to-operate, high-precision, high efficiency, and perfect welding effects, can meet various efficient and precise welding requirements.

As a professional laser welding machine manufacturer in China, IGOLDENLaser has 12 years of experience in designing and manufacturing handheld laser welders. IGOLDEN’s provides a wide range of laser welding machines with power ranges from 200W, 300W, 1000W, 1500W, 2000W, and 3000W.

Based on different mechanical designs, the collection of IGOLDEN’s laser welders includes handheld laser welders, desktop laser welders, gantry-type laser welding machines, and boom arm laser welding machines catering to diverse applications.

Laser Welding Machine Cost and Price

The cost of a laser welding Machine varies widely. It mainly depends on its power, features, and intended use. Different users have different price ranges. However, we have categorized this price table into five main categories to simplify the discussion.

Laser Welding Machine Price (Entry Level)

The entry-level laser welding machines cost around $4,600. Usually, these machines come with a 1,000W laser source. For newbies, they are a cheap choice. Artists can also use them to make a lot of cool things. These tools work great for small jobs and things that aren’t heavy.

Affordable 1500W Laser Welder

The laser welding machine cost of a 1500W laser welder ranges from $4,800 to $5,200. This range is ideal for small businesses. If you work in light-duty welding, these machines are a perfect option. There is also a little more laser power to work with more materials than essential laser welders.

2000W Laser Welding Machine Price

A 2000W laser welding machine costs between $6,800 and $7280. This model is much more powerful than the above two types. If you are looking for a laser welder for small to medium-sized businesses, 2000W laser welders are perfect. They provide more stability and precision for most laser welding works.

3000W Laser Welding Machine Price

A 3000W Laser welding machine costs around $9800. These machines are primarily ideal for commercial use. They are incredibly capable of doing large-scale projects. You can mostly find them in industrial manufacturing.

Combo Laser Welders or Multi-purpose 3-in-1 Portable Handheld Laser Welding Machine

A portable 3-in-1 laser welding machine combines laser cutting, cleaning, and welding. These machines are budget-friendly compared to the number of services they can offer. The laser welding cost of these devices ranges from $5000 to $6800. These machines are highly flexible.

Factors Affecting the Laser Welding Machine Cost

When you see a laser welding machine’s cost or price tag, you must know that several factors are responsible for it. Each factor significantly influences the price and determines the device’s suitability.

Factor #1 The Type of Laser

The first thing that highly affects the cost of a laser welding machine is the type of laser used. As you know, a laser welding machine may come with three main types of laser sources.

Fiber lasers are widely famous for their efficiency and power. Due to their advanced technology, people prefer this laser source for industrial applications. However, fiber lasers are more expensive.

CO2 lasers are much cheaper than fiber laser welders. These machines are also versatile and often used for cutting and engraving projects. However, they may not produce the best welding results as fiber lasers can.

Solid-state lasers, especially Nd: YAG lasers, are also widely used for laser welding. These laser welders can make precise welds on a variety of materials. However, the manufacturing process is a bit tricky, so the laser welding costs of these types are not cheap.

Factor #2 Power Output

The power output of the laser welders is the next thing that affects the laser welding cost. It directly determines the ability to handle different materials and thicknesses. Indeed, machines with higher power can weld thicker materials. They are faster and also need high cost.

Low Power Machines (up to 1000W)

These laser welding machines are suitable for small-scale applications. They work great on thinner materials. The laser welder price of these machines is more affordable. These machines do a great job if you are a hobbyist or a small business.

Medium-Power Machine (1000W to 2000W)

These laser welders are more versatile and can handle various materials. You can use these machines to create most of our daily used items. They are excellent for small to medium-sized manufacturing operations.

High-power machines (3000W and above)

These laser welding machines are used for heavy-duty applications. They are typically designed to weld thicker materials. Although they are more expensive, they are perfect for large-scale production.

Factor #3 Laser Welding Machine Features

The laser welding machine’s price also differs based on the features that come with the machine. Some laser welders offer combo features, like 2 in 1 or 3 in 1. These machines offer both cutting, cleaning, and welding capabilities.

Laser welding machines may also feature manual or automated operations. Most handheld laser welders are cheaper than industrial automated welders. However, manual laser welders do not come with advanced technology.

On the other hand, automated laser welding machines are more expensive than manual ones. However, they offer greater precision, consistency, and efficiency. They also reduce the need for manual labor, saving costs in the long run.

Factor #4 Flexibility and Versatility

The flexibility means how easily you can use the laser welder. On the other hand, versatility means how many items you can weld under a laser welding machine. These two factors highly affect the cost of laser welding.

Laser welders with more versatility can handle a wide range of applications. Some laser welders can not weld steel, while some can weld all metals. Some laser welders come with single welding modes, while others come with multiple modes.

Spot welding, butt welding, seam welding, and many more welding modes are there. Each mode is very important when dealing with various metal parts.

Factor #5 Portability

Portable laser welders are generally lightweight and come with low-power laser sources. They are either battery-powered or wired. The battery-powered later welders are heavy cause you have to carry large batteries. However, you can take these welders anywhere you want.

Conversely, wired handheld laser welders must have a nearby power source. However, they can handle high-power applications.

Portable laser welding machines are typically cheaper than desktop laser welders. However, combo laser welders might cost more. Laser power directly affects the laser welder cost.

Factor #6 Build Quality

The build quality affects the cost of the laser welding machine and the machine’s durability. Machines with high-quality components are more expensive, but they offer excellent performance.

High-quality machines are made with durable materials, and the components used in these devices are advanced. Here are some things to look for when judging the quality of a laser welding machine.

First, check the laser source and its brand. Raycus, MAX, and BWT are the three most popular laser sources in laser welding machines. These high-quality laser sources are built to last. Second, check the cooling system. How fast can the machine dissipate heat? Are there any extra ventilation systems? Third, check the strength of the machine’s body. Is it made of ordinary steel or a high-quality material that doesn’t break easily?

Why are Laser Welding Machine Parameters Important?

Understanding laser welding machine parameters is extremely important. Why? In one sentence, it plays a crucial role in the success of the welding process. They directly impact the quality, strength, and consistency of the welds. You can get efficient and reliable outcomes by adequately setting these parameters.

Laser Power directly determines weld penetration and fusion depth. If you give too much power, it may create overheating. On the other hand, if you set little power, it may not produce strong welds.

Welding speed also plays a critical role here. It directly affects the heat distribution. Faster speeds create weaker welds, while slower speeds may cause overheating or distortion. The focal spot generally creates the energy density. If the focal spot is misaligned, it can lead to poor-quality welds.

Therefore, understanding the laser welding machine parameters is vital for three reasons:

(1) You can improve productivity by learning the laser welding parameters. Note that optimized parameters reduce welding time and ensure a faster job done.

(2) Proper settings always reduce material waste and can save energy costs.

(3) When you learn more about the laser welding parameters, you can technically work with more metals. For example, many people struggle to work with reflective materials. Most of them think it is impossible to work with reflective metals. But in reality, it is not. All you need to understand is how laser beams work in reflective materials. You have to insert the right laser welding parameters setting.

Key Laser Welding Machine Parameters

In general, there are four key laser welding machine parameters. Combining these four parameters, you can achieve a good laser welding outcome. However, you must know how you are adjusting them. To learn more about these parameters, you can check the user manual that comes with the machine.

Laser Power

Laser power is typically the energy output of the laser beam. You will often find it measured in watts (W). Laser power determines how much heat the laser generates to melt or fuse materials.

For example, a 1000W laser produces 1000 joules of energy per second. This machine can handle 0.5 to 3mm of stainless steel, 0.5 to 2 mm of aluminum, and so on. Higher power allows for deeper penetration. Note that a higher-power laser welder isn’t always better for all metal parts. They create severe damage to the delicate metal parts. So, you must adjust the laser power based on the metal parts you are dealing with.

The laser power is adjusted in the settings as a percentage. For example, using a 1000W laser welder will set the laser power to 50% for 1mm stainless steel. Most machines use a control panel UI to change all these settings.

IGOLDENCNC laser welders have a digital display where you can easily adjust all the laser welding parameters. This control panel supports 20+ languages.

Welding Speed

Welding speed is how fast your laser welder moves along the weld joint. It is easy to picture in your mind. When you use faster welding speeds, your metal parts take less time to dissipate the heat. Thus, this welding method reduces the heat input. However, you may get weak welds. The opposite happens when you use slower welding speeds.

Therefore, the welding speed can be adjusted using the control panel. Always make sure that the speed and quality of the weld are equal. The best practice is to test the speed on scrap metal parts.

Focal Spot Size

The focal spot is critical terminology in laser tech. When a laser hits a surface, the diameter of the laser is the focal spot size. Remember that the smaller the size, the higher the laser energy. Consequently, the higher concentration means a higher energy density for precision welding.

This laser setting is excellent for thicker materials because the more prominent spots spread the energy over a large area. You can change the size of the target spot by moving the laser head or using the machine’s focus-adjusting settings.

Pulse Parameters

You can generally find two laser welding machines based on laser pulses. The pulsed laser machine produces a short burst of laser energy emitted at intervals. On the other hand, the continuous laser welding machine continuously produces laser energy.

Adjusting this laser welding parameter is crucial for the laser welder you use. Usually, it has the pulse length, frequency, and peak power. Short pulses work best when making small, complicated welds, while longer pulses work best when making thicker welds.

You can also change these numbers to fit your needs by changing the pulse settings on your laser welder. Always do the proper tests to avoid burning or welds that aren’t full.

Factors That Affect Laser Welding Machine Parameters

Laser welding machine parameters heavily depend on several factors. If you don’t know about these factors and adjust the laser welding parameters, you might experience poor results. Therefore, always test settings on scrap material. You could also refer to the user manual for guidance.

Material Type

Different materials respond differently to laser welding. Although steel has a very high melting point, it is easier to weld than aluminum.

Aluminum is reflective and has excellent thermal conductivity. So, some energy is reflected when you focus a laser beam to weld aluminum parts. Also, the created head at the focused area quickly dispersed around it. Therefore, when you deal with aluminum, you must opt for higher laser power.

Material Thickness

Material thickness also affects the parameters of laser welding machines. Thicker materials require more laser power for penetration, while thinner materials require less power to prevent burn-through.

For example, 1mm stainless steel requires 500W laser power, 800 mm/s speed, 5kHz frequency, and a 2mm focus. On the other hand, 1.5 mm stainless steel requires 500W of laser power and 750 mm/s welding speed. Therefore, the laser parameters should be carefully adjusted based on the material thickness.

Shielding Gas

Shielding gas generally protects the weld from oxidation and contamination. Argon, helium, and nitrogen are the most commonly used gases. The type and flow rate of the gas affects weld quality and appearance. Improper shielding might cause porosity and discoloration.

Beginner’s Guide to Operating a Laser Welding Machine

Are you ready to use your laser welding machine? Wait a while and consider the pre-processing steps. Did you forget about the safety and proper calibration of your device? Yes, these two steps are crucial for every laser welding task.

Ensure Safety First!

The laser beam welder creates a highly focused laser beam to melt and fuse metal. So, indeed, if this laser comes in contact with your skin, it may burn the place it touches. You must be careful, especially when you are dealing with reflective metals.

(1) Wear laser safety glasses to protect your eyes.

(2) Wear gloves and protective clothing to prevent burns.

(3) Ensure the workspace is well-ventilated to remove fumes.

(4) Keep a fire extinguisher near your working place.

(5) Above all, follow all machine-specific guidelines.

Set-up the Machine

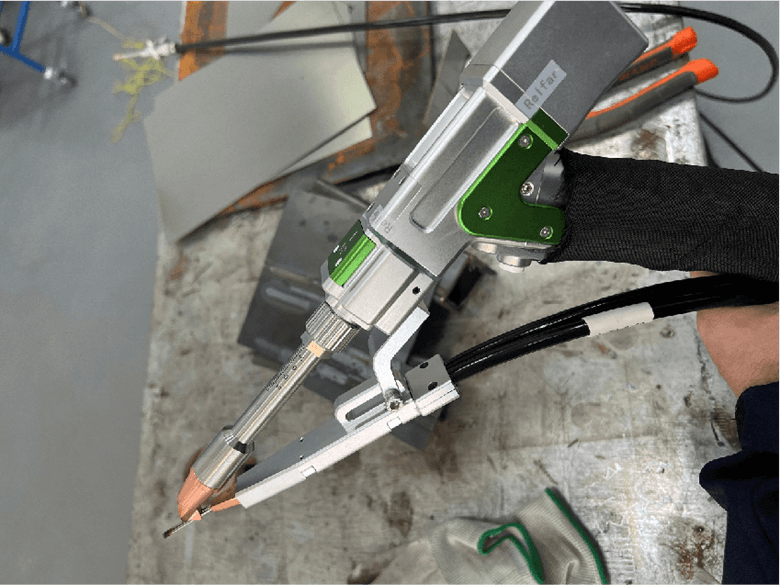

There are two types of typical handheld laser welding machines: with and without a wire feeder. The most common one is usually the one with the wire feeder. Jewelry, battery production, and delicate component welding may not require a wire feeder.

Whatever the type is, they usually come in a box with disassembled parts. Don’t worry! The central controller unit and the wire feeder typically come in correctly assembled. You must assemble the laser gun based on your appropriate project. Also, you must connect the optical cable with the laser gun and the machine. Next, properly install the wire feeder with the laser gun and the wire feeder machine. You might find other parts as well; all you need to do is follow the proper guidelines from the manufacturer.

Once you have installed all necessary parts, calibrate the laser settings and wire feeder connections. A few laser welding machines may come with shielding gases, which you can check if required.

Step By Step Process of Operating a Laser Welding Machine

Before operating your laser welding machine, you must calibrate the device correctly. You have already checked the wire feeder connection, laser gun, and cooling system. Also, make sure that you have the proper safety gear.

Step #1 Prepare your workpiece

You must be careful with the metal parts, not only the laser welding machine. Is it clean enough for laser welding? Note that the contamination can weaken the weld seam. Dust and debris interfere with the metal welding joints. So, clean your metal part before the primary process.

Next, place the workpiece on a stable surface. You can also use a fixture to keep it steady during welding. Since you are dealing with two metal parts, ensure they are correctly aligned.

Step #2 Adjust the laser parameters

Now, come to the laser welding display. Find settings, and choose the desired settings language. In IGOLDENCNC, there are 20+ languages. So, these machines are straightforward to use, and people from any country can easily set up the device.

Set the appropriate laser power, pulse duration, and frequency. Note that you must consider various factors to choose the correct settings. In this case, you can get help from the manufacturers. At IGOLDENCNC, we always provide laser settings for different metals of different grades. So you don’t have to worry about calculating or finding the appropriate laser settings.

Step #3 Perform and Observe the Actual Welding Process

Once everything is ready, start the welding machine and monitor the process. If you are a beginner, you can first test the laser settings on a scrap piece to ensure you are dealing with the correct laser parameters.

You must ensure the welding speed and beam intensity are consistent during laser machine welding. This will provide a strong and smooth weld. Also, always stay focused and observe the weld pool formation.

Step #4 Clean Up the residue

Finally, once the welding is complete, check for imperfections. Clean off any remaining residue, such as slag or oxidation. In this case, you can use a brush or air blast. If necessary, you can also polish the welded area.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.