Buyer Guide

Mdf Acrylic Laser Cutting Engraving Machine for Sale

An MDF acrylic laser cutting and engraving machine is a computer-controlled machine that utilizes laser technology to cut and engrave materials such as MDF (medium-density fiberboard) and acrylic. It offers precise and efficient cutting and engraving capabilities for various applications.

80w 100w 120w 150w 180w 1390 single head Co2 laser cutting engraving machine

Introducing our versatile and reliable 1390 single head Co2 laser cutting and engraving machine, available in six power options ranging from 80w to 180w to suit all your needs. Whether you’re a small business owner, an artist, or an industrial manufacturer, this machine is the perfect addition to your workspace.

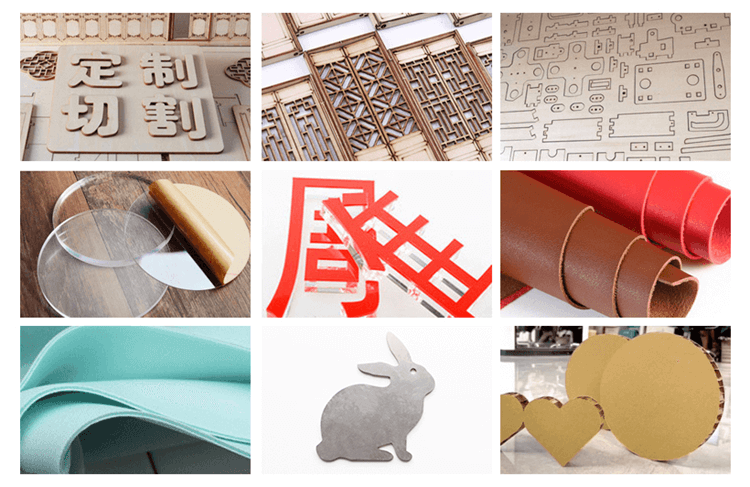

With its high precision and fast cutting speed, the 1390 laser cutting and engraving machine is capable of cutting and engraving a variety of materials such as acrylic, wood, leather, paper, cloth, and more. Its large working area of 1300mm x 900mm allows you to work on larger projects with ease.

The machine’s user-friendly software allows for easy customization of your designs, while the high-quality laser tube ensures accurate and consistent results. The machine’s design is also optimized for safety, with a built-in laser protection system and an emergency stop button.

Whether you’re looking to create custom signs, engravings, or cut intricate designs, our 1390 single head Co2 laser cutting and engraving machine has got you covered. And with its durable construction and easy maintenance, you can trust that it will be a reliable addition to your workspace for years to come.

The 80W, 100W, 120W, 150W, 180W, and 1390 single-head CO2 laser cutting engraving machine is a versatile and high-performance tool designed for precision cutting and engraving applications. This machine utilizes a single CO2 laser head, offering different power options to meet various requirements.

With its cutting-edge technology and robust construction, this laser cutting engraving machine provides exceptional accuracy and efficiency. It is capable of cutting and engraving various materials such as wood, acrylic, leather, fabric, paper, and more, making it suitable for a wide range of industries including signage, woodworking, crafts, and prototyping.

The power options available for this machine include 80W, 100W, 120W, 150W, 180W, and 1390. These power levels determine the machine’s cutting and engraving capabilities, allowing users to select the appropriate power for their specific needs. Whether you require intricate engraving or fast cutting speeds, there is a power option available to match your requirements.

The machine features a user-friendly interface, making it easy to operate and control. It comes equipped with advanced software that enables precise design and layout customization, ensuring accurate results. The machine also offers a spacious working area, allowing for the processing of large-sized materials.

Safety is a top priority with this CO2 laser cutting engraving machine. It incorporates various safety features such as an emergency stop button, protective housing, and laser beam shielding, ensuring the protection of both the operator and the surrounding environment.

In summary, the 80W, 100W, 120W, 150W, 180W, and 1390 single-head CO2 laser cutting engraving machine is a high-quality and versatile tool suitable for a wide range of cutting and engraving applications. Its different power options, user-friendly interface, and safety features make it an ideal choice for businesses and individuals seeking precision and efficiency in their laser processing tasks.

Features of Laser Cutting Machine

- Precise engraving , professional engraving optical lens with more stable light beam.

- Equipped with red light position, making locating more convenient and precise, low friction coefficient, low noise and high speed.

- High-quality laser tube, laser power supply, reduce the failure rate.

- Lift platform is optional, the lifting height can be up to 300mm.

- High-performance motherboard: support U disk to read, with power continuous carving, slope carving, color separation output and other functions.

- Rotary carving fitting can be optional according to customer requirements, to solve the difficulties in carving for cylinder and irregular products.

- Design software of CAD, AI, Coreldraw are all supported for friendly human-computer interface and demand of the industries on-the-spot.

Applicable Industries of Acrylic Laser Cutting Engraving Machine:

Advertising decoration, craft and gifts, packaging and printing, toys, electron, model, building decoration, etc.

Applicable Materials of Acrylic Laser Cutting Engraving Machine :

Acrylic, Double-color sheet, MDF, non-metal materials like leather, cloth, rubber, wooden boards, bamboo products, organic glass, plastics, marble, jade, crystal, etc.

Key Points About Mdf Acrylic Laser Cutting and Engraving Machine

Laser Technology: These machines use laser beams to cut and engrave materials. The laser beam is generated by a laser tube and directed through a series of mirrors to the cutting or engraving surface. The intensity and focus of the laser beam can be controlled to achieve different effects.

Material Compatibility: MDF and acrylic are commonly used materials in many industries and applications. MDF is a versatile wood composite that can be cut and engraved with a laser. Acrylic is a thermoplastic known for its transparency and durability. Laser cutting and engraving machines designed for MDF and acrylic can handle various thicknesses and sizes of these materials.

Cutting: MDF acrylic laser cutting machines use the laser beam to vaporize or melt the material along a programmed cutting path, resulting in precise and clean cuts. The focused laser beam creates a narrow kerf, allowing for intricate designs and sharp corners. The cutting process is computer-controlled, enabling high accuracy and repeatability.

Engraving: Laser engraving involves using the laser beam to remove material from the surface of MDF or acrylic, creating etched or engraved designs. The laser can engrave text, images, logos, and intricate patterns onto the material. The depth and intensity of the engraving can be adjusted to achieve different effects.

Design Flexibility: MDF acrylic laser cutting and engraving machines offer great design flexibility. They can work with vector-based designs created in software such as CorelDRAW or Adobe Illustrator. These machines can cut and engrave complex shapes, curves, and fine details with high precision, allowing for customization and personalization.

Speed and Efficiency: Laser cutting and engraving machines provide fast and efficient processing of MDF and acrylic materials. The speed at which the machine moves and the power of the laser can be adjusted to optimize cutting and engraving time while maintaining quality.

Ventilation and Safety: Laser cutting and engraving machines generate smoke and fumes during the process. It’s important to have proper ventilation and extraction systems in place to remove the emissions and ensure a safe working environment. Operators should follow safety guidelines, wear appropriate protective gear, and be trained in the operation of the machine.

Maintenance and Support: Regular maintenance is necessary to keep the laser machine in optimal condition. This includes cleaning the optics, checking the alignment, and replacing consumables such as laser tubes and lenses. Choose a machine from a reputable manufacturer that provides technical support, training, and access to spare parts.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.