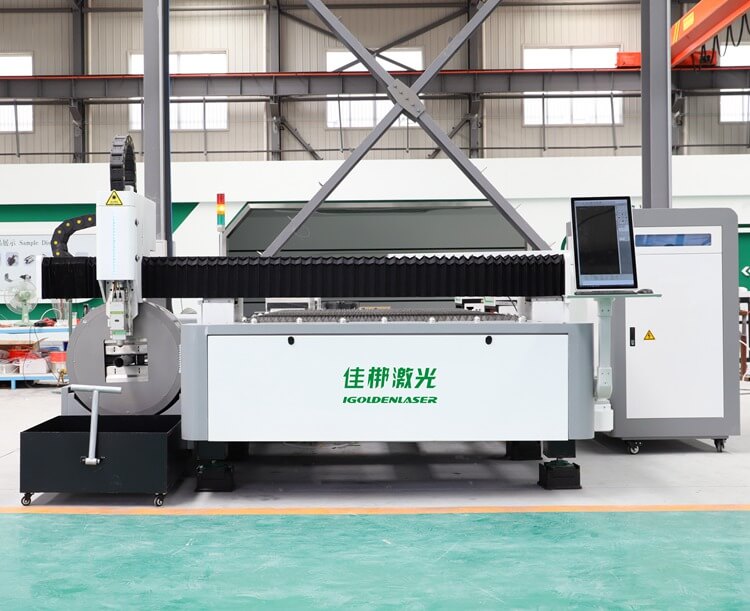

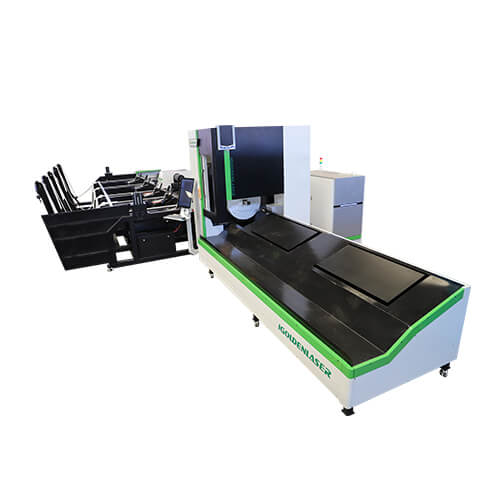

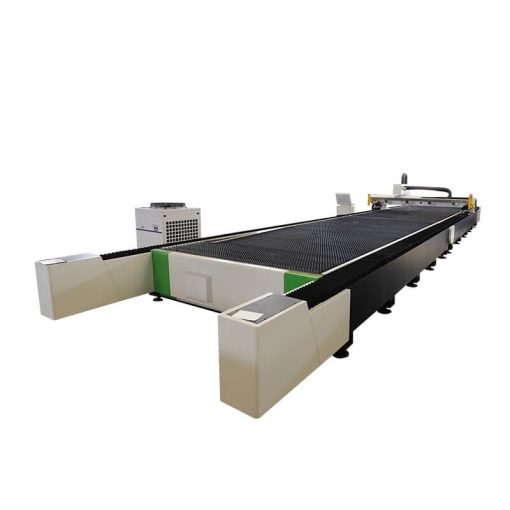

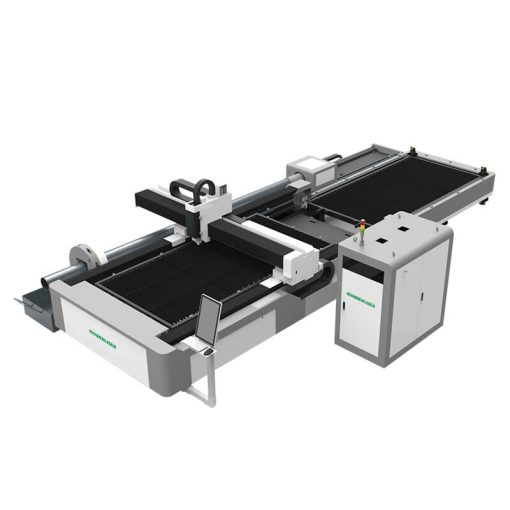

iGR-FH(+T) Series

Plate and Tube Laser Cutting Machine

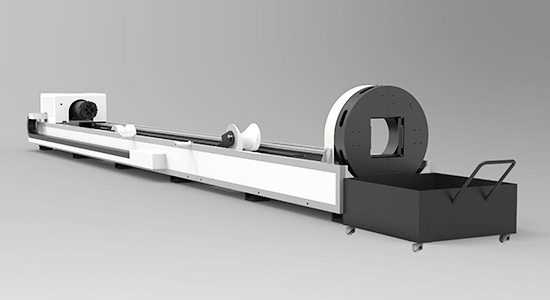

The dual-use fiber laser cutting machine can realize the cutting of two different materials on the same equipment. It can cut both metal plates and tubes (including square tubes, round tubes, channel steel, angle steel, etc.). One machine with multiple functions, high cost performance, professional pipe cutting control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

The plate and tube integrated laser cutting machine can be said to be a multi-purpose machine, so that metal cutting machine manufacturers can cover most industries with just one machine. After buying a plate and tube integrated laser cutting machine, manufacturers no longer have to worry about changing the industry.

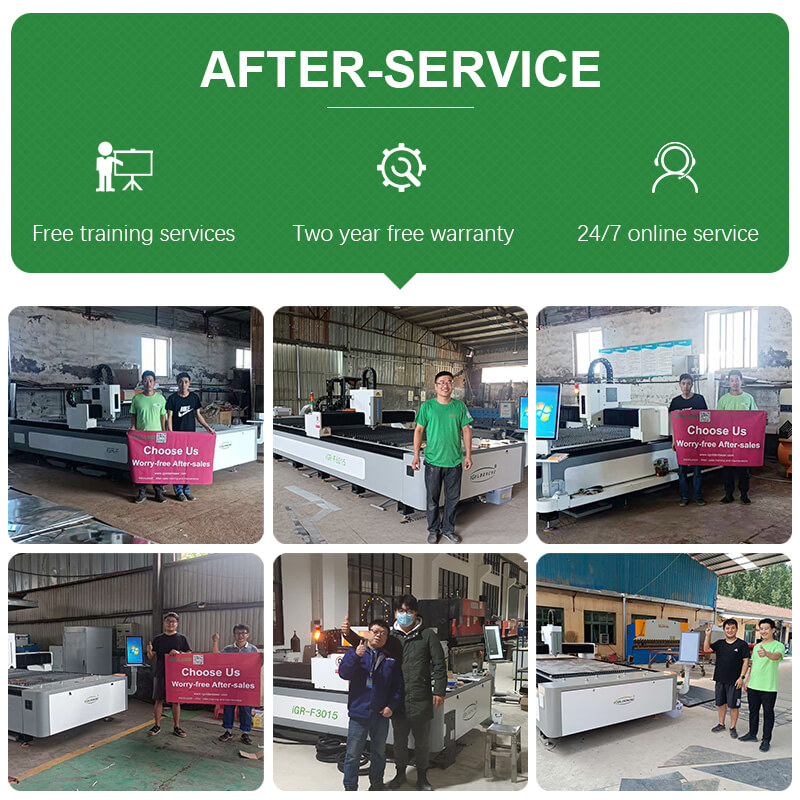

Paul –

We are really happy with the machines and support from the sales. Let me introduce you to my friend Davor. He is interested in buying the fiber laser cutting machine from you.

KevinWilson –

I purchased this laser around the beginning of last month and shortly after, ordered a rotary roller kit for cylindrical, conical or irregularly shaped objects. Not hard to assemble and setup with the manual came with it. Actually works just fine once you figure out the software and drivers. Although adjusting the parameters to cut plywood at different depths went through a learning curve, as did getting the rotary attachment to work properly, but that’s not the fault of the laser cutter itself. If you’re willing to take more time to learn how to use the software, it’s easy to get various successful projects completed.