Laser Engraving Machine for Metal

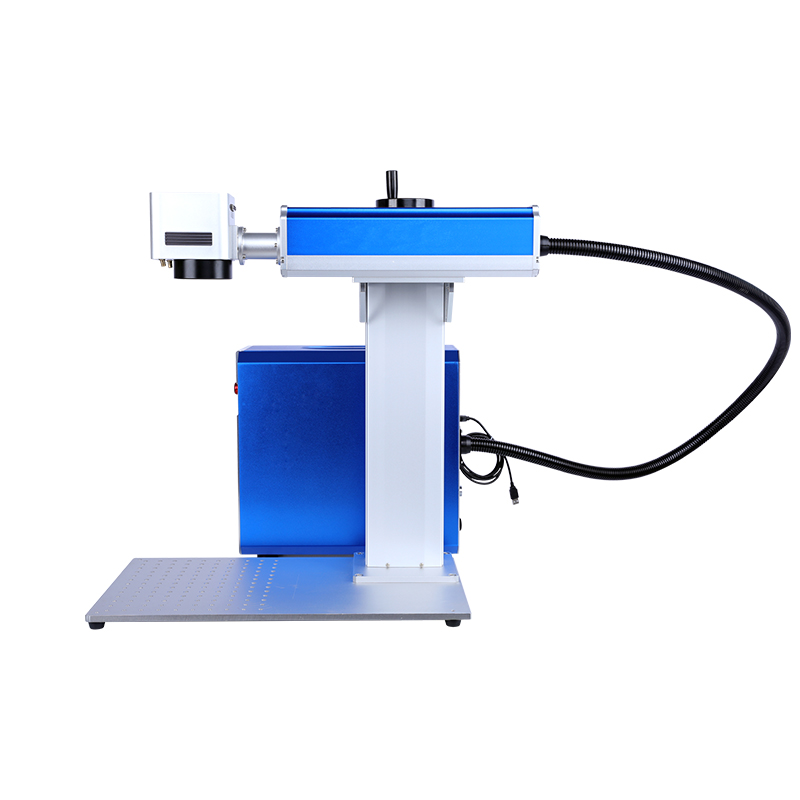

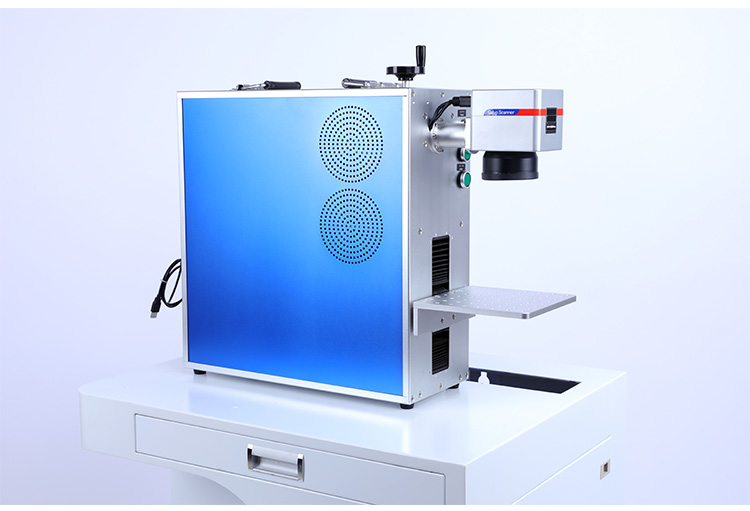

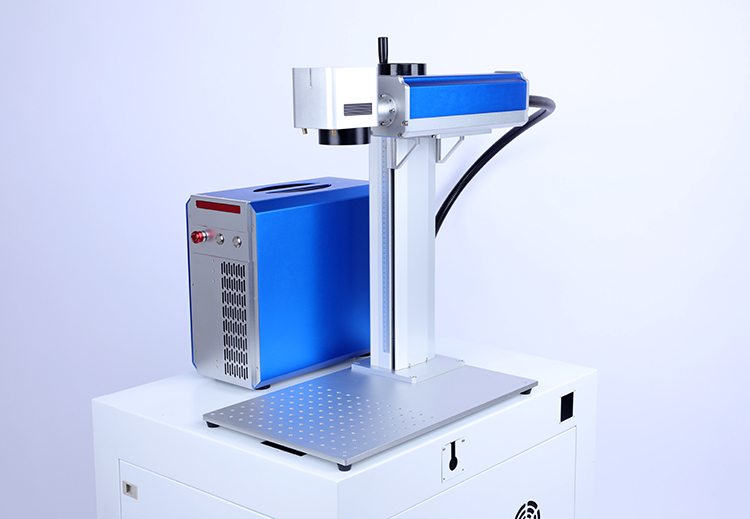

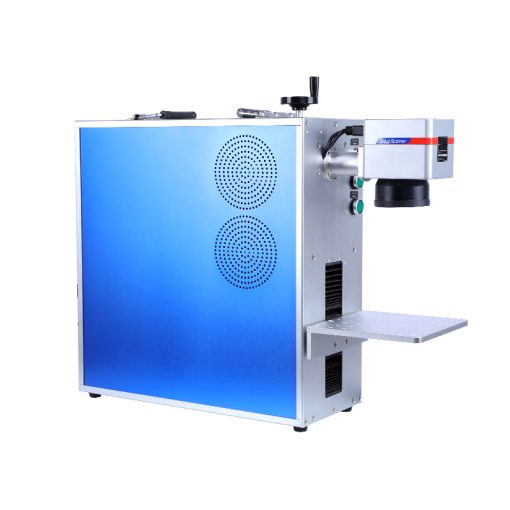

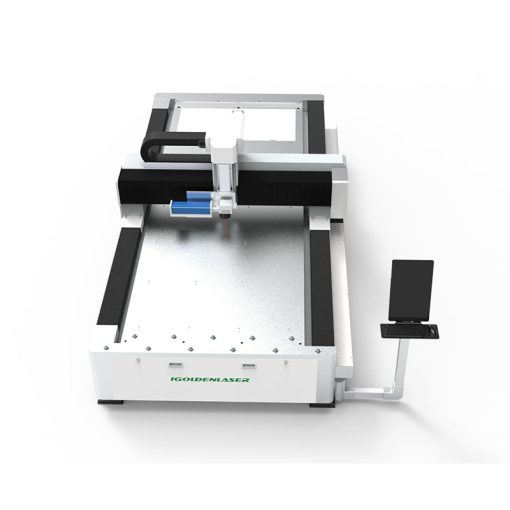

Laser engrave and mark your barcodes, serial numbers, text, and logos on to metal with an IGOLDENLaser fiber metal marking machine. Our fiber laser machines can engrave or mark all types of metals including stainless steel, aluminum, tool steel, brass, titanium, and much more, allowing you to create a variety of mark types in no time!

Browse our fiber laser machines that allow you to easily laser etch and engrave on metal materials. From jewelry engravings to kitchenware barcode etching, invest in a fiber laser marking machine and expand your product portfolio. You can even engrave a variety of colors onto metal with our MOPA fiber laser engraving machines!

Laser marking has become one of the most popular manufacturing processes today, especially for manufacturers and service providers that handle metals. Adding complicated designs on metal sheets can now be done in mere minutes thanks to high-power laser machines.