Buyer Guide

Metal Pipe Laser Cutting Machine

The rapid development of intelligent manufacturing has led to the rapid rise of the industrial market. Laser cutting machines have replaced traditional metal cutting technology. Now the market for tube cutting is also rapidly rising. With its powerful functions, tube laser cutting machines have successfully emerged in the market. , And gradually replace the traditional cutting technology.

Suitable for various materials and thicknesses:

The tube laser cutting machine has the ability to easily cut various materials, such as stainless steel, carbon steel, aluminum and aluminum alloy, copper, brass, bronze, titanium and other metal tubes, and the thickness range that can be cut is from 0.5mm to 10mm or more.

metal tube laser cutting machine

Tube laser cutting machine can bring a lot of convenience, so what are the advantages of tube laser cutting machine?

Precise repeatability:

The multi-dimensional laser tube cutting machine can simply and accurately process products repeatedly, which is very important in the case of mass production.

Improve edge quality:

Compared with the traditional method, the laser pipe cutting machine can provide a very smooth cutting end face. Because the process is non-contact nature, it will not cause tool wear, nor will it directly exert mechanical force on the part, thereby preventing material deformation or workpiece contamination. The heat affected zone (HAZ) is also reduced.

tube laser cutting machine

fast:

Compared with traditional cutting machines, tube laser cutting machines are faster and more efficient, which greatly saves costs and enhances the company’s market competitiveness.

Easy to maintain:

The fragile and consumable parts of the metal laser pipe cutting machine are relatively cheap, such as the nozzle and lens, which makes its maintenance cost lower.

Shorten delivery time:

The laser pipe cutting machine can cut almost any size, type and shape of metal material pipes, so the delivery time provided is very short, which is somewhat difficult for the traditional pipe cutting machine.

Accurate result:

The tube laser cutting machine is completely controlled by computer automatically, avoiding the interference of human factors, so the accuracy of the production results can be achieved.

Professional Tube Laser Cutting Machine

Laser cutting of tubes and pipes provides cost and part quality advantages than traditional plasma or oxygen cutting. High precise laser cutting meets the high tolerances demand in the production, without grinding or other re-work. The cut edges are ready for welding without any additional weld prep. Laser cutting consolidates multiple operations to reduce multiple setups, additional handling, and labor.

Applicable Materials

Stainless steel, carbon steel, aluminum, brass, copper, alloy steel and galvanized steel etc.

Applicable Industry

Metal furniture, medical device, fitness equipment, sports equipment, oil exploration, display shelf, agriculture machinery, bridge supporting, steel rail rack, steel structure,fire control, metal racks, agriculture machinery,automotive, motorcycles, pipes processing etc.

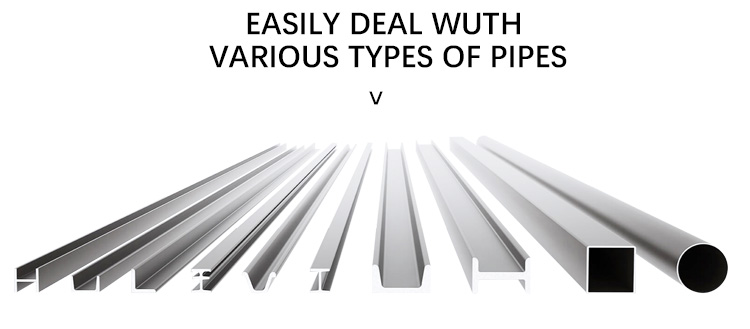

Applicable Types Of Tubes Cutting

Round tube, square tube, rectangular tube, oval tube, OB-type tube, C-type tube, D-type tube,triangle tube, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option).

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.