No products in the cart.

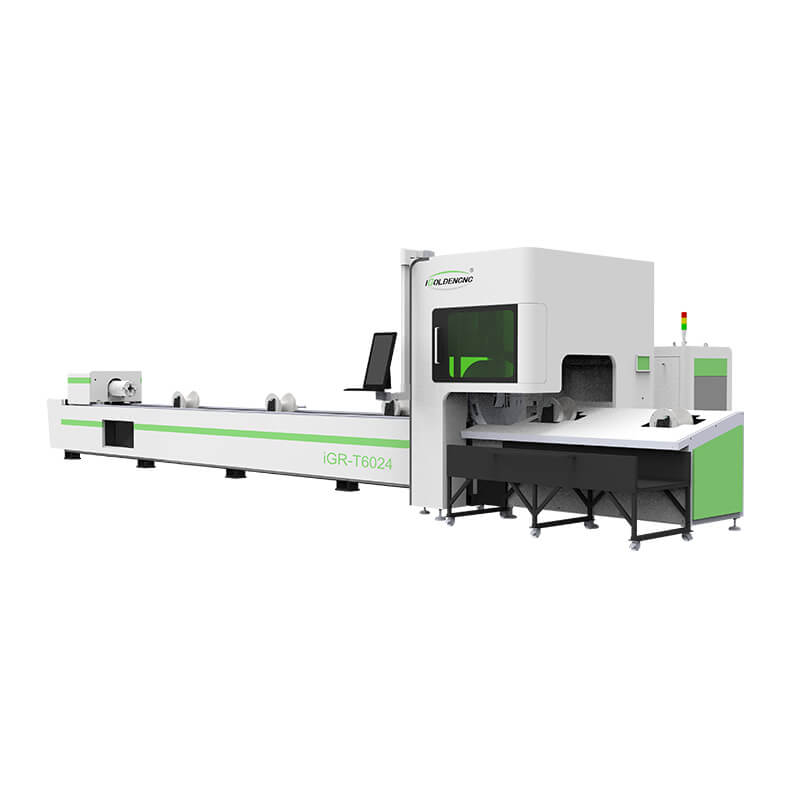

iGR-T Series

Fiber Laser Pipe Cutting Machine

Tube laser cutting machine is specially designed for metal tube cutting laser cutting machine. It can cut round tubes, square tubes, oval tubes, rectangular tubes and irregular tubes. It is equipped with a special cutting operating system, the system is simple to operate, high precision, professional and stable, suitable for professional profile cutting, widely used in sports equipment, oil pipelines, chemical equipment and other industries.

The cutting system of the IGR series automatic laser pipe cutting machine can cut on any side of the pipe or along the length of the pipe. Different processing procedures can be automatically completed at one time in one device. The system can cut square tubes, round tubes, rectangular tubes, oblate tubes and other metal materials such as stainless steel, carbon steel, aluminum alloy, titanium alloy, and bronze. Professional laser tube processing with less floor space, high degree of automation, faster processing efficiency, more flexible processing graphics, and lower processing costs.

Week –

Easy to assemble, everything plugged in as it should. Control panel is user friendly. Software came with the all-in-one fiber laser metal cutter is easy to use, enabling automation and modular cut in metal fabrication.

Andre Blake –

I am a customer from Iceland. When I bought this fiber laser cutting machine, I was still worried about whether it could be delivered to my port smoothly, but in the end, it proved that these concerns were wrong, and my machine was delivered quickly. Arrived at my factory.