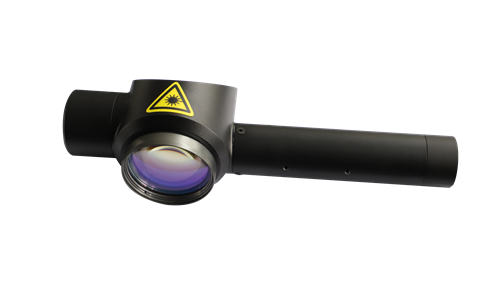

IGCL-MOPA(100w-200w)

Portable Laser Cleaning Machine

The portable laser cleaning machine is a newly launched laser cleaning tool. The cleaning machine has many advantages such as portable and lightweight, flexible and adjustable parameters, wireless control, etc. It can efficiently remove rust, stains, oil stains, coatings, etc. on the surface of the workpiece, and is suitable for Mechanical processing, cultural relics restoration, mold cleaning, food processing, electronic circuits and other industries, using the characteristics of precise positioning, can meet the processing of a variety of modeling workpieces and achieve efficient cleaning effects.

The cleaning machine is portable integrated design, super integrated injection molding case, buffer design, anti-pressure, anti-fall wear. Pull rod chassis, can be carried on high-speed rail and air consignment.

Bruce –

The laser cleaning machine is really good,it can clean my machine efficiency.