Buyer Guide

Multi Layer Fabric Cutting Machine for Garment

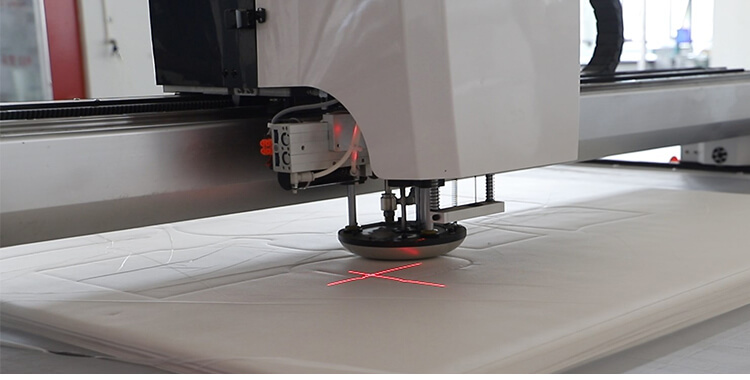

In the textile industry, efficiency and precision are paramount. One of the most revolutionary advancements in this field is the multi-layer fabric cutting machine. This sophisticated piece of equipment has transformed the way fabrics are cut, ensuring accuracy, speed, and minimal waste.

Multi Layer Fabric Cutting Machine

A multi-layer fabric cutting machine is a type of automatic cutting equipment specifically designed for cutting multiple layers of fabric at once. It is commonly used in industries such as garment manufacturing, upholstery, and textile production.

Automatic fabric cutting is differentiated from user-operated manual cutting by its countless advantages. While manual cutting is carried out by an operator, automatic cutting utilises a combination of technologies that allow for 2-dimensional cutting of materials placed on a reel and/or in a sheet.

Then there’s the automatic conveyor fabric cutting system, which is characterised by the application of a made-to-measure feeder which functions like a conveyor belt. It allows the material on the cutting table to be automatically laid. This keeps the size of the machine under control while guaranteeing excellent performance and extreme precision.

Choosing an automatic fabric cutting system means extreme precision as well as speed and efficiency. This type of cutting system makes it possible to speed up cutting, even particularly difficult materials, and reducing times while increasing production volumes. Efficiency is also given by the reduction of costs and waste, which are drastically reduced thanks to a lower possibility of human errors and impressive energy performance.

Multi Layer Fabric Cutting Machine Features

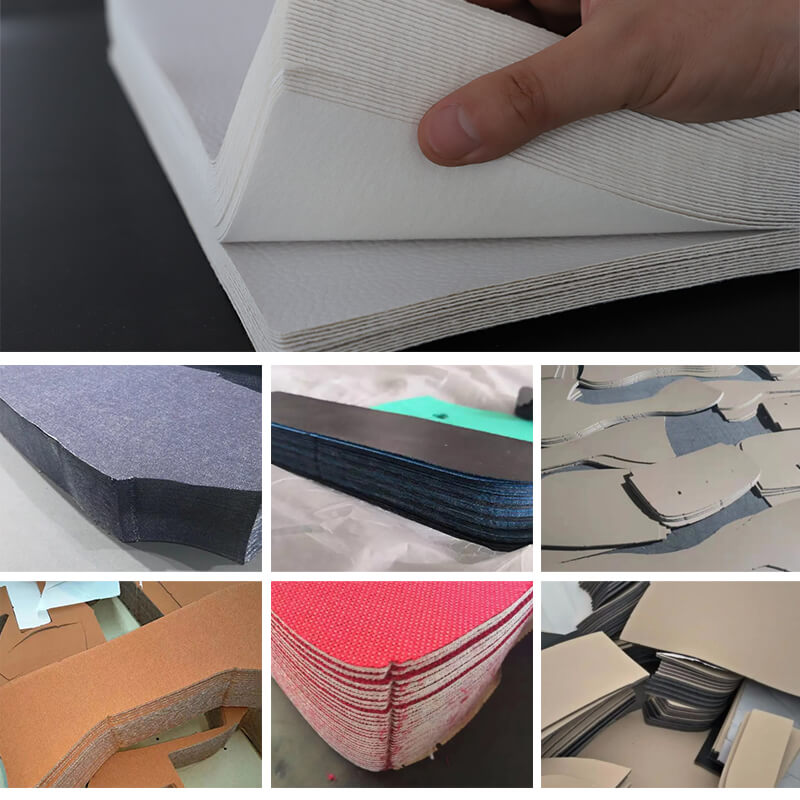

- Multi-layer fabric cutting machines are capable of cutting a large number of fabric layers simultaneously, ranging from 20 to 100 layers or more, depending on the machine’s specifications.

- These machines are equipped with advanced cutting technology, such as computerized control systems and high-precision cutting tools, ensuring accurate and consistent cutting results.

- By cutting multiple layers at once, multi-layer fabric cutting machines significantly increase production efficiency and save time compared to manual cutting methods.

- These machines can handle various types of fabrics, including woven fabrics, knitted fabrics, synthetic fabrics, and even delicate or stretchy materials.

- Multi-layer fabric cutting machines can be programmed to cut fabric according to specific patterns and designs, allowing for customization and flexibility in production.+

Multi Layer Cutting Machine Applications:

- Garment manufacturing: Multi-layer fabric cutting machines are widely used in the garment industry for cutting fabric panels for clothing, such as shirts, pants, dresses, and jackets. They enable efficient mass production and precise cutting of fabric pieces.

- Upholstery and furniture production: These machines are also utilized in the upholstery and furniture industry for cutting fabric covers, cushions, and other fabric components. They ensure accurate and uniform cutting of fabric layers, resulting in high-quality finished products.

- Textile production: In textile manufacturing, multi-layer fabric cutting machines are employed for cutting fabric rolls into smaller pieces or shapes, such as for quilting, bedding, curtains, and home textiles. They enhance productivity and reduce material waste.

- Automotive and aerospace industries: Multi-layer fabric cutting machines are used in the production of automotive interiors, seat covers, and aircraft interiors. They enable efficient cutting of fabric layers for these specialized applications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.