Buyer Guide

Open Type CNC Laser Cutting Machine

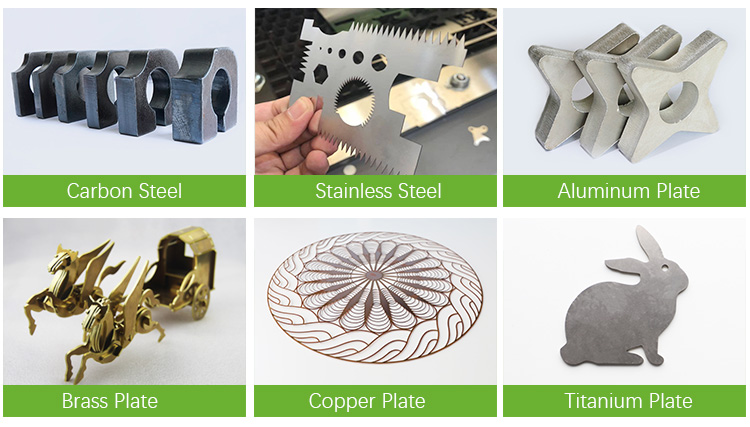

CNC fibre laser cutting machine for metal sheets & plates of stainless steel, galvanized steel, carbon steel, aluminum, alloy, brass, bronze, iron, copper and other metal materials with different thicknesses. Fiber laser cutting system has become increasingly popular in the metal fabrication industry due to its speed, accuracy, and ability to cut a wide range of materials.

Open Type Fiber Laser Cutting Machine for Sheet Metal

An open type laser cutting machine is a versatile tool used in various industries for precision cutting and engraving of different materials. It utilizes a laser beam to melt, burn, or vaporize the material, resulting in accurate and intricate cuts. The “open type” designation refers to the machine’s open structure, which allows for easy loading and unloading of materials and provides flexibility for working with large or irregularly shaped objects.

This high power fiber laser cutting machine is specifically engineered for processing a wide range of metal sheets, including but not limited to stainless steel, galvanized steel, carbon steel, aluminum, alloy, brass, bronze, iron, and copper. Its high power can cut and engrave various thicknesses, allowing for precision cutting of thin and thick metal materials. Whether dealing with intricate designs or bulk production, this metal fiber laser cutter offers consistent and accurate results across diverse metal types and thicknesses.

Open Type Laser Cutting Machine Features:

Open type structure for easy loading and unloading.

Single working table saves floor space.

Drawer trays facilitate the collection and cleaning of small parts and scraps.

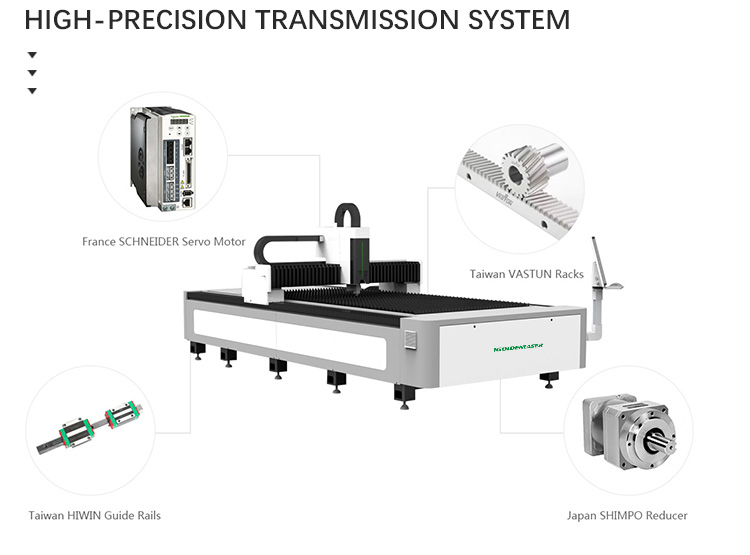

Gantry dual-drive configuration, high damping bed, good rigidity, high speed and high acceleration speed.

Open Type Laser Cutting Machine Details:

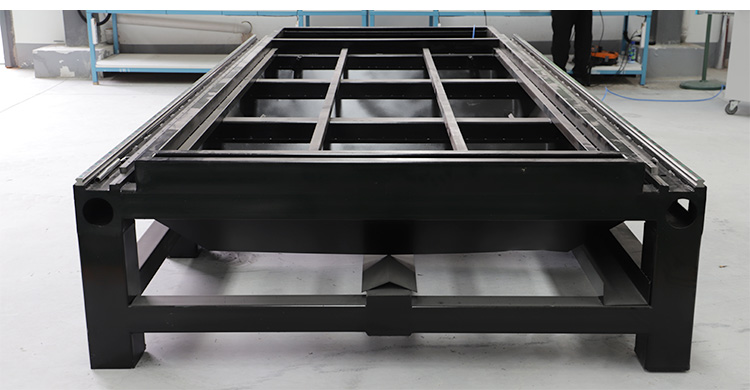

- High-rigidity machine bed, exclusive high-temperature numerical control furnace annealing pro-cess, can guarantee the stability of the machine tool for a long time.

- Imported original packaged fiber laser, good beam quality, stable performance, non-reflective lenses, no need to adjust the optical path, basic maintenance-free, the service life of up to more than 100,000 hours.

- The fiber laser has high electro-optical conversion efficiency and conversion efficiency can reach 30%, which can greatly save power consumption during operation and has extremely low operating.

- Cutting speed, operating costs are extremely low, rapid return on investment.

- For a variety of metal sheet, mainly applies to stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass plate, aluminum plate, manganese steel, various alloy plates, rare rapid cutting of metal and other materials.

Open type fiber laser cutting machine find applications in various industries, including:

Open type fiber laser cutting machine offer high precision, speed, and flexibility for cutting a wide range of materials, particularly metals. Their open structure allows for easy material handling, and their fiber laser technology provides excellent cutting performance and efficiency. These machines are widely used in various industries that require precise and efficient cutting and engraving capabilities.

Application Materials: Suitable for metal cutting with Stainless Steel Sheet, Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Iron Plate, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.

Metal Fabrication

Open type fiber laser cutting machines are widely used in metal fabrication, sheet metal processing, and manufacturing industries.

Automotive Industry

Fiber laser cutting machines are employed in the automotive industry for cutting and shaping metal components used in vehicle bodies, frames, chassis, and other parts. They offer precise and efficient cutting of complex shapes and contours.

Aerospace Industry

Open type fiber laser cutting machines are utilized in the aerospace industry for the production of aircraft parts and components.

Electronics Industry

Fiber laser cutting machines are used for precision cutting of thin materials, such as printed circuit boards (PCBs), electrical components, and semiconductor materials. They provide high accuracy and speed, making them suitable for the electronics industry’s demanding requirements.

Decorative and Architectural Applications

Open type fiber laser cutting machines enable the creation of intricate designs and patterns on metal surfaces, making them ideal for decorative applications in architecture, interior design, and artistic creations.

Laser Cutting Machine Working Process

Design Input: The user creates a digital design or pattern using computer-aided design (CAD) software. This design specifies the shape and dimensions of the desired cut.

Digitalization: The design is converted into a digital format compatible with the laser cutting machine’s controller.

Material Setup: The material to be cut is placed on the worktable of the laser cutting machine. The material may be sheet metal, wood, acrylic, leather, or various other materials.

Calibration: The laser cutting machine is calibrated to ensure accurate positioning and focus of the laser beam. Laser Activation: The laser source is activated, and the laser beam is directed through the optical system to the material’s surface.

Cutting Process: The focused laser beam heats and vaporizes or melts the material along the programmed cutting path. The high energy density of the laser allows for precise and clean cuts.

Motion Control: The motion system moves the laser head and/or the worktable according to the programmed instructions, guiding the laser along the designated cutting path.

Cooling and Assist Gas: During the cutting process, a cooling system may be used to prevent overheating. Additionally, assist gases (such as nitrogen or oxygen) may be employed to improve the cutting efficiency and remove debris from the cut.

Completion: Once the cutting process is complete, the laser cutting machine stops, and the cut pieces are removed from the worktable. Laser cutting is widely used in various industries for its precision, speed, and versatility in cutting different materials. It’s commonly employed in metal fabrication, signage, aerospace, automotive, and other manufacturing applications.

Open Type Fiber Laser Cutting Machine Cutting Parameters

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Carbon Steel O₂ | 1 | 7.0-9.0 | 9.0-12.0 | 10.0-12.0 | 10.0-12.0 | 8.0-12.0 | 8.0-12.0 | 8.0-12.0 | 8.0-12.0 | 1 |

| 2 | 3.0-3.7 | 4.8-5.5 | 5.0-6.0 | 5.5-7.0 | 6.0-7.5 | 6.0-7.5 | 6.0-7.5 | 6.0-7.5 | 2 | |

| 3 | 2.0-2.5 | 3.0-3.8 | 3.8-4.2 | 4.0-4.6 | 4.3-5.2 | 3.5-5.0 | 3.5-5.0 | 3.8-5.0 | 3 | |

| 4 | 1.4-1.7 | 1.8-2.2 | 2.5-3.0 | 2.5-3.2 | 2.8-3.7 | 3.0-4.2 | 3.3-4.5 | 3.5-4.5 | 4 | |

| 5 | 1.0-1.5 | 1.5-1.8 | 1.5-2.2 | 1.8-2.5 | 2.2-3.1 | 2.5-3.6 | 2.8-3.6 | 3.0-3.8 | 5 | |

| 6 | 0.6-0.8 | 1.2-1.5 | 1.2-1.8 | 1.6-2.2 | 1.8-2.6 | 2.4-3.0 | 2.5-3.2 | 2.6-3.2 | 6 | |

| 8 | 0.9-1.1 | 1.0-1.2 | 1.1-1.5 | 1.2-1.3 | 1.8-2.4 | 1.9-2.5 | 2.0-2.6 | 8 | ||

| 10 | 0.6-0.9 | 1.0-1.2 | 1.1-1.2 | 1.2-1.8 | 1.7-2.1 | 1.8-2.2 | 10 | |||

| 12 | 0.9-1.0 | 0.9-1.1 | 1.0-1.5 | 1.0-1.5 | 1.5-2.0 | 12 | ||||

| 16 | 0.65-0.75 | 0.7-0.85 | 0.7-0.85 | 0.7-0.9 | 16 | |||||

| 20 | 0.6-0.75 | 0.6-0.75 | 0.6-0.8 | 20 | ||||||

| 22 | 0.4-0.6 | 0.4-0.6 | 22 | |||||||

| 25 | 0.4-0.6 | 25 | ||||||||

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Stainless steel N₂ | 1 | 8.0-10.0 | 11.5-13.5 | 14.0-16.0 | 16.0-18.0 | 20.0-28.0 | 20.0-28.0 | 35.0-42.0 | 50.0-70.0 | 1 |

| 2 | 2.0-2.5 | 3.2-3.8 | 4.0-5.0 | 5.0-7.0 | 9.0-13.0 | 9.0-13.0 | 15.0-23.0 | 30.0-40.0 | 2 | |

| 3 | 1.0-1.5 | 2.0-3.0 | 3.2-4.5 | 4.0-6.5 | 4.0-6.5 | 7.0-11.0 | 17.0-22.0 | 3 | ||

| 4 | 1.2-1.6 | 2.0-2.8 | 3.0-4.5 | 3.0-4.5 | 4.0-6.0 | 9.0-14.0 | 4 | |||

| 5 | 0.7-1.0 | 1.2-2.0 | 1.4-2.5 | 1.4-2.5 | 2.5-4.0 | 7.0-12.0 | 5 | |||

| 6 | 0.7-1.0 | 0.9-1.8 | 0.9-1.8 | 2.0-3.2 | 5.0-8.0 | 6 | ||||

| 8 | 1.2-1.8 | 3.8-5.0 | 8 | |||||||

| 10 | 0.7-0.9 | 1.6-2.5 | 10 | |||||||

| 12 | 1.1-1.8 | 12 | ||||||||

| 16 | 0.7-1.2 | 16 | ||||||||

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Aluminum alloy N₂ | 1 | 8.0-10.0 | 4.5-6.0 | 8.0-10.0 | 8.0-10.0 | 10.0-15.0 | 28.0-35.0 | 30.0-39.0 | 50.0-60.0 | 1 |

| 2 | 2.0-2.5 | 1.5-2.5 | 3.8-4.5 | 3.8-4.5 | 5.0-6.0 | 12.0-16.0 | 12.0-22.0 | 22.0-35.0 | 2 | |

| 3 | 1.4-2.0 | 1.4-2.0 | 2.5-3.5 | 6.5-8.0 | 6.0-13.0 | 12.0-18.0 | 3 | |||

| 4 | 1.4-2.0 | 3.5-5.0 | 3.8-5.5 | 9.0-12.0 | 4 | |||||

| 5 | 0.8-1.0 | 2.5-3.5 | 2.8-4.0 | 4.5-8.0 | 5 | |||||

| 6 | 1.8-3.0 | 2.5-3.5 | 3.8-6.0 | 6 | ||||||

| 8 | 0.9-1.3 | 0.8-1.6 | 1.8-3.0 | 8 | ||||||

| 10 | 0.5-1.0 | 1.0-2.1 | 10 | |||||||

| 12 | 0.8-1.5 | 12 | ||||||||

| 16 | 16 | |||||||||

| Material | Thickness(mm) | 500W | 800W | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | Thickness(mm) |

| cutting speed | ||||||||||

| Brass N₂ | 1 | 2.0-3.5 | 4.5-6.0 | 4.5-8.0 | 8.0-12.0 | 10.0-16.0 | 20.0-32.0 | 23.0-30.0 | 40.0-55.0 | 1 |

| 2 | 0.7-1.0 | 1.0-2.0 | 2.5-3.5 | 3.5-5.0 | 6.0-8.0 | 9.0-11.0 | 9.0-13.0 | 30.0-35.0 | 2 | |

| 3 | 2.0-3.0 | 2.5-4.0 | 5.0-6.5 | 5.0-6.5 | 11.0-18.0 | 3 | ||||

| 4 | 1.6-2.2 | 3.0-4.5 | 3.0-5.2 | 7.5-10.0 | 4 | |||||

| 5 | 0.7-1.2 | 1.5-2.0 | 1.8-3.0 | 5.5-7.0 | 5 | |||||

| 6 | 1.0-1.6 | 1.3-2.0 | 3.2-4.5 | 6 | ||||||

| 8 | 0.6-0.8 | 1.5-2.2 | 8 | |||||||

| 10 | 0.7-1.2 | 10 | ||||||||

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.