Buyer Guide

Paper Cut Laser Machine

Laser cutting machines work by using a high-powered laser beam to vaporize or melt the material along a designated path, resulting in a clean and precise cut. These machines can be equipped with different types of lasers, such as CO2 lasers or fiber lasers, depending on the specific application and material being cut.

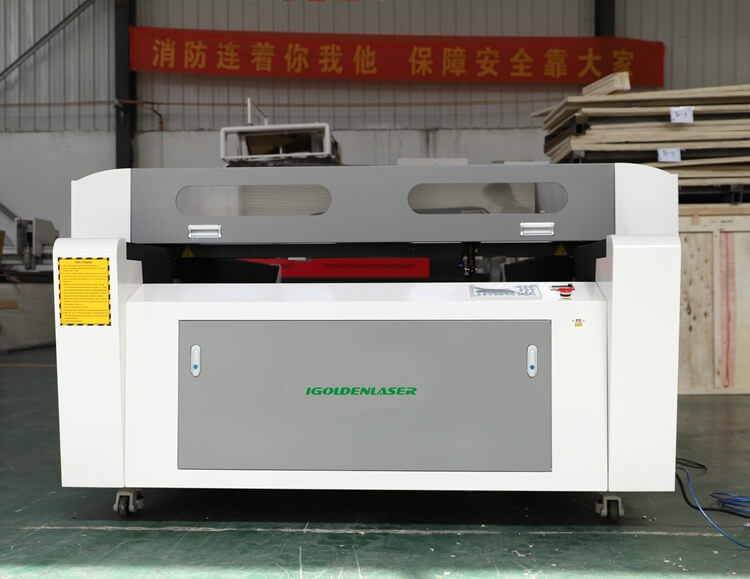

Laser Paper Cutting Machine

CO2 laser cutter is the best laser machine uses CO2 laser cutting technology (CO2 laser beam) to cut and engrave wood, MDF, acrylic, plywood, PVC, plastic, paper, jeans, ABS, fabric, PVB, textile, leather, stone, glass, thin soft metals, etc, which has wide applications in the advertising industry, crafts industry, packing industry, garment industry, educational institution, small business, and so on.

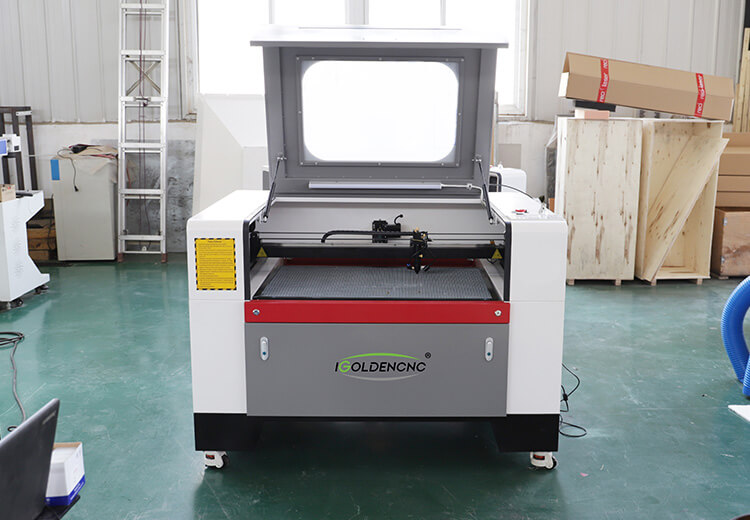

Laser Paper Cutting Machine

CO2 laser cutting machines cut paper and cardboard with fine and accurate results. This makes it widely used in the printing industry, packaging industry, and art design. Because laser cutting is non-contact, it can achieve high-precision cutting of thin paper and avoid physical pressure and deformation.

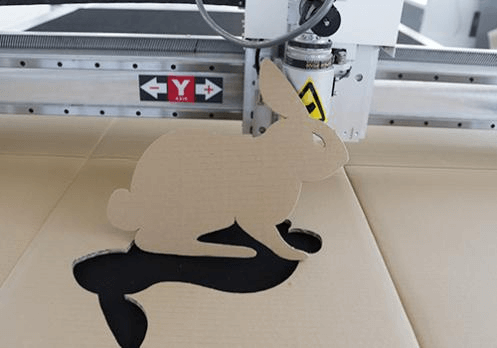

When it comes to paper cutting, laser machines offer several advantages over traditional methods. They can produce intricate and detailed designs with high precision, allowing for the creation of complex patterns and shapes. Laser cutting is also a non-contact process, which means there is no physical force applied to the paper, reducing the risk of damage or distortion.

Additionally, laser cutting machines can be computer-controlled, which enables the replication of designs with accuracy and the ability to create custom cuts easily. This makes them suitable for various applications, including arts and crafts, paper prototyping, packaging, and more.

CO2 Laser cutting machines are versatile and can handle a wide range of paper types, including cardstock, cardboard, chipboard, and even thin fabrics. This makes them suitable for various applications, such as creating invitations, greeting cards, paper models, stencils, and more.

Laser cutting machines offer exceptional precision and accuracy when cutting paper. They can achieve very fine cuts, allowing for intricate designs and complex shapes. The laser beam is highly focused, resulting in clean edges without fraying or tearing the paper.

Laser cutting machines are typically controlled by computer software. You can design your cutting patterns using graphic design software or dedicated laser cutting software. These programs allow you to create or import vector files, specify cutting paths, adjust settings, and preview the results before sending the instructions to the laser cutter.

Laser paper cutting machines offer several advantages:

- Laser cutting provides high accuracy and intricate detailing, allowing for complex designs to be cut with precision.

- These machines can cut various types of paper materials, including cardstock, cardboard, adhesive-backed paper, and more.

- Laser cutting is typically faster than traditional methods such as manual cutting or die cutting, especially for complex designs.

- Once the design is set up, the cutting process can be automated, reducing the need for manual intervention.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.