Buyer Guide

PET, PETG and Plastics CO2 Laser Cutter

Material information for the PET/ PETG and laser cutting method:

PET PETG PET, which stands for polyethylene terephthalate, is a clear, strong and lightweight plastic belonging to the polyester family. PET is the world’s packaging choice, or made into carpet, clothing, automotive parts, construction materials, industrial strapping, and scores of other products. PET film is often an excellent choice for more demanding applications in food and nonfood-film applications.

Major uses include packaging, plastic wrap, tape backing, printed films, plastic cards, protective coatings, release films, transformer insulation films and flexible printed circuits. PET can be a valuable companion material to laser cutting. Additionally, PETG offers exceptional clarity, toughness, high chemical resistance and excellent forming capabilities, and perfect for marking and cutting with CO2 laser.

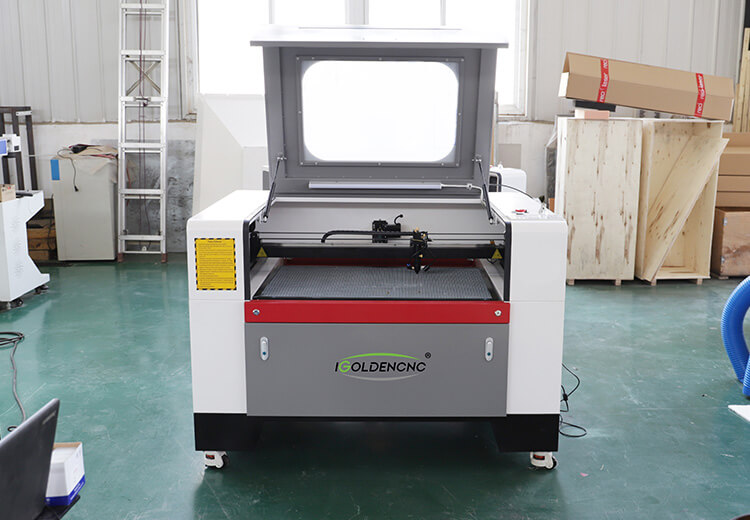

CO2 laser cutting machine

Lasers are growing in popularity among fabricators working with a wide range of materials. Offering exceptional clarity, toughness, high chemical resistance and excellent forming capabilities, PET or PETG sheet can be a valuable companion material to laser cutting. CO2 laser is capable of cutting PET or PETG with speed, flexibility, and pinpoint precision, allowing the creation of practically any shape to exacting specifications. CO2 laser cutter designed and built by iGoldenlaser is ideally suitable for cutting PET or PETG.

The benefits of cutting PET/PETG using lasers:

- Clean and perfect cuts – No post-processing necessary.

- High precision – Perfectly accurate laser cutting.

- High flexibility for cutting any shapes and sizes No tool wear.

- Consistent high cutting quality

- No forces acting on the material means no mechanical stresses

- Highly cost-efficient production from small batches up to medium sized serial production

PET (Polyethylene Terephthalate) and PETG (Polyethylene Terephthalate Glycol) are commonly used thermoplastic materials. Laser cutting is a popular method for cutting and engraving various materials, including plastics. However, when it comes to PET and PETG, laser cutting can be a bit tricky due to the nature of these materials.

PET and PETG have a lower melting point compared to other thermoplastics, such as acrylic or polycarbonate. This lower melting point makes them more susceptible to heat damage during laser cutting. The laser’s heat can cause the material to melt excessively, resulting in poor cut quality, melted edges, and even deformation of the material.

CO2 laser cutting machines are commonly used for cutting plastics. They have a wavelength of around 10.6 micrometers, which is well-absorbed by organic materials like PET and PETG. PET and PETG require lower power settings and higher cutting speeds compared to other plastics. This helps minimize heat buildup and reduce the chances of excessive melting. It’s crucial to conduct some test cuts to determine the optimal power and speed settings for your specific machine and material.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.