Buyer Guide

Plasma Metal Cutting Machines

Plasma Metal Cutting Machines

The plasma metal cutting machines provided by our company include metal flat plasma cutting machine, metal plate and tube integrated plasma cutting machine,metal square tube plasma cutting machine, portable metal plasma cutting machine, round tube plasma cutting machine, gantry plasma cutting machine.

Do you have a thought to DIY or buy an affordable CNC Plasma Cutter? We’ll provide you with the competitive CNC Plasma Table with expert customer service to satisfied your requirements.

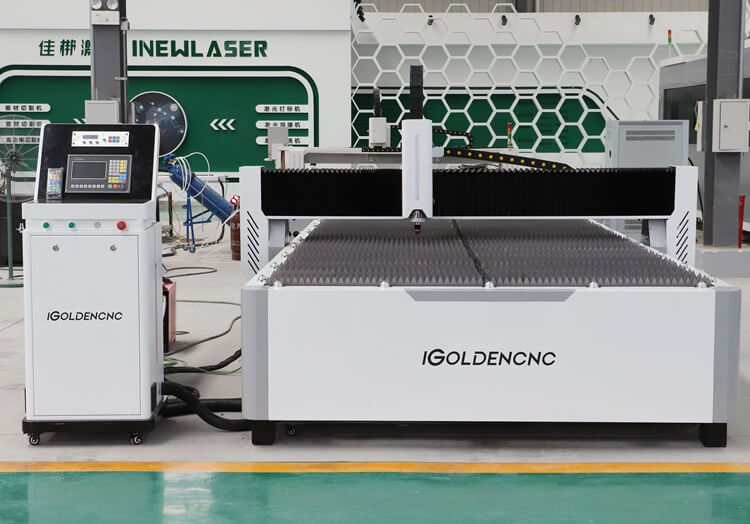

CNC Metal plasma table

CNC plasma tables by iGOLDEN provide a broad range of cutting solutions. Designed for top-notch cut quality, a iGOLDENCNC plasma table is durable enough to run full production for years, yet nimble enough to cut intricate shapes with ease. iGOLDEN is here to help you select the best CNC plasma cutting table to meet your specific needs.

The table cuts a 4×4 4×8 5×10 area and works well with 4×8 and 4×10 sheets. In fact, the software allows you to automatically layout and cut 4×8 or larger (up to 20 ft long) shapes.

Industrial CNC cutting table system offers all the features to get started on cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics. The included Digital Torch Height Controller maintains distance between the plasma torch and your work – producing smooth edges, sharp details and high precision.

Gantry type metal plasma cutting machine

Heavy Frame Metal Plasma Cutting Machine Sheet Tube Metal Cutting CNC Plasma Cutter Gantry Plasma Flame Cutting Machine

1. Heavy-duty gantry cutting machine adopts heavy-duty frame, heavy-duty guide rail, good stability, large span, the gauge has a width of 4 meters, 5 meters, and 6 meters, and the length can be from 8 meters to tens of meters.

2. It can realize double flame or double plasma cutting at the same time, forming 2 workpieces at a time, increasing double efficiency, saving half of the time, half of labor and one piece of equipment.

3. Equipped with high-power plasma power supply, such as 200A 300A 400A, to achieve plasma thick plate cutting. The plasma cutting speed is 3-5 times that of flame cutting, which improves production efficiency.

4. Multi-head plasma or flame straight cutting can be added, multiple workpieces at the same time, saving time.

5. The heavy-duty gantry cutting machine has beautiful appearance and high-end atmosphere, demonstrating the strength of the enterprise and improving its competitiveness among competitors.

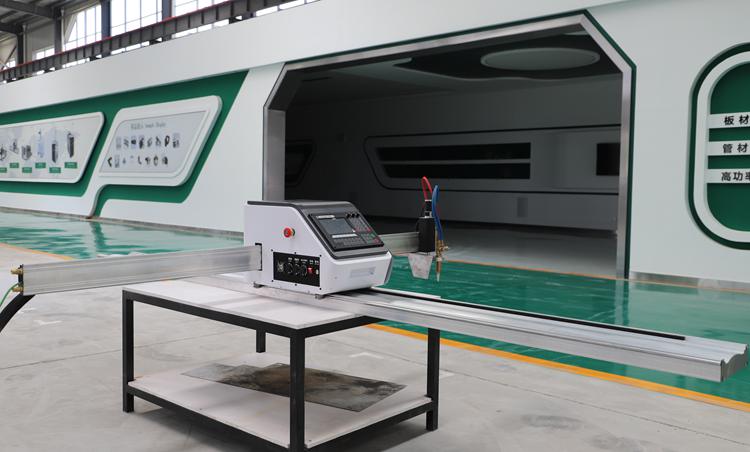

Portable metal Plasma cutting Machine

A new portable design man carried construction is applied to the mini CNC plasma cutter machine here. Although it is small in volume, it can still cut 5ft x 10ft metal sheets as the stroke for X & Y axis is 1500x3000mm. The portable design enables us to put the plasma cnc in any location as the production needs. Let us give an example to interpret this point here. Suppose we want to cut a 12-meter-long steel plate, and such a large steel plate is not easy to move. So how do we put it on the machine to cut it? Taking the portable cnc plasma cutter here, we put it on the metal plate, and then we start the equipment to cut. Therefore, it is the right solution for the giant metal materials cut. Except for the plasma torch, it has a flame cutting torch also. 5ft x 10ft Portable cnc flame plasma cutting machine for sale with unmatched service now!

Portable metal Flame/Plasma Cutting Machine

- Mini portable design, Man-carried construction; Two options available on stroke: 1500x3000mm (5ft x 10ft) and 1500x2500mm (5ft x 8ft). Mini cnc plasma cutter with portable design

- The default configuration coming with two torches, one plasma cut torch, and one Oxy-fuel flame cutting torch. plasma torch of mini cnc plasma cutter

- The portable cnc plasma cutter is equipped with an automatic torque height controller (THC controller). auto torch height control of mini cnc plasma cutter

- Professional plasma cutting controller dedicated for portable plasma cnc – STARFIRE control system with LED display in English. mini cnc plasma cutter control system

- A cut drawing library with rich resources is built into the cnc system. Production cuts can be executed by simply setting the size parameters. drawing library in the mini plasma cutter system

- Plug and Play design. mini cnc plasma cutter with plug and play design ● X & Y axis is adopting rack and pinion transmission. rack on mini cnc plasma cutter.

What is Plasma Cutting?

Plasma cutting is a process that involves cutting through electrically conductive materials using an accelerated jet of hot plasma. The technology harnesses the power of ionized gas to melt and expel material from the cut, resulting in clean and precise cuts.

How Does a Plasma Cutter Work?

A plasma cutter works by sending an electric arc through a gas that is passing through a constricted opening. The gas can be oxygen, nitrogen, argon, or even shop air. This elevates the temperature of the gas to the point that it enters a plasma state. The plasma is then directed at the workpiece, melting the metal and blowing it away.

Components of a Plasma Metal Cutting Machine

Power Supply

The power supply is the heart of the plasma cutter. It provides the energy required to maintain the plasma arc. Modern power supplies are designed to deliver consistent power, ensuring smooth and efficient cutting.

Plasma Torch

The plasma torch is the tool that directs the plasma arc onto the workpiece. It consists of several components, including the electrode, nozzle, and swirl ring, each playing a crucial role in the cutting process.

Control Console

The control console allows the operator to adjust the cutting parameters, such as speed, amperage, and gas flow. Advanced consoles come with digital displays and programmable settings for enhanced precision.

FAQ

What materials can a plasma cutter cut?

Plasma cutters can cut a variety of electrically conductive materials, including steel, aluminum, brass, and copper.

How thick can a plasma cutter cut?

The cutting thickness depends on the power of the plasma cutter. Some machines can cut materials up to several inches thick.

Is plasma cutting safe?

Yes, plasma cutting is safe when proper safety measures are followed, including wearing PPE and ensuring adequate ventilation.

Can plasma cutters be used for precision cutting?

Yes, plasma cutters are known for their precision and can produce clean, accurate cuts suitable for various applications.

What is the lifespan of a plasma cutter?

The lifespan of a plasma cutter depends on its usage and maintenance. Regular maintenance can extend the life of the machine significantly.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.