Laser Knowledge

Plexiglass Laser Drilling and Cutting

While laser cutting is a popular method for shaping plexiglass, laser drilling is another technique that allows for precise perforations in the material. In this article, we will explore the fascinating world of plexiglass laser drilling, its benefits, applications, and the process behind this advanced technology. Let’s

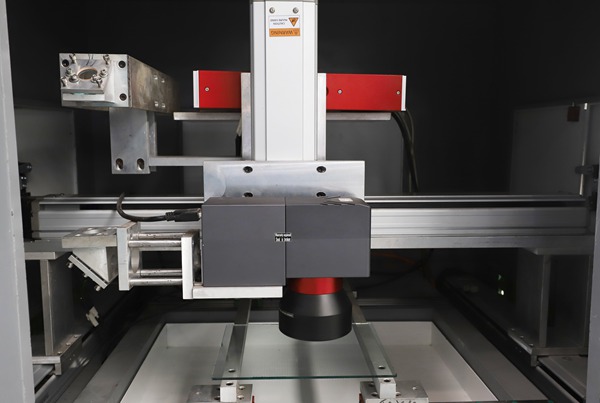

Plexiglass Laser Drilling and Cutting Machine

Plexiglass laser drilling is a process that uses a high-powered laser beam to create precise holes or perforations in plexiglass material. The laser beam is focused on a specific point, melting or vaporizing the material to create the desired hole size and shape. Laser drilling offers several advantages over traditional drilling methods, making it a preferred choice for many applications.

The Process of Plexiglass Laser Drilling

The process of plexiglass laser drilling involves several steps to achieve accurate and clean perforations. Let’s take a closer look at each step:

- Design Preparation: The first step in plexiglass laser drilling is to prepare the design that requires perforations. This can be done using specialized software or computer-aided design (CAD) programs. The design can range from simple hole patterns to complex arrangements, depending on the application.

- Material Selection: Choosing the right type and thickness of plexiglass is crucial for successful laser drilling. Different types of plexiglass have varying properties, such as transparency, flexibility, and heat resistance. The thickness of the material also affects the drilling process and the quality of the perforations.

- Machine Setup: Once the design and material are selected, the laser drilling machine needs to be set up accordingly. This involves adjusting the laser power, speed, and focus to ensure optimal drilling results. The machine’s software is programmed with the design specifications, including the position and size of each perforation.

- Laser Drilling: With the machine properly set up, the plexiglass sheet is placed on the drilling bed. The laser beam is then directed onto the material, focusing on the designated drilling points. As the laser beam makes contact with the plexiglass, it heats the material, causing it to melt or vaporize and create the desired holes. The high precision of the laser beam ensures clean and accurate perforations.

- Finishing Touches: After the drilling process is complete, the plexiglass piece may require some finishing touches. This can include removing any residue or burrs from the drilled holes, ensuring a smooth and clean finish.

Application range:

Gem & glass cover plate / optical glass / semiconductor package chip / sapphire / silicon wafer / ceramic substrate and other brittle materials, heat-sensitive polymer / inorganic materials, micro drilling / cutting

LCD panel cutting

Optical lens shape cutting

Organic cover plate and optical lens shape cutting

Novel flexible display or fine electronic circuit etching/cutting of organic/inorganic materials

Applications of Plexiglass Laser Drilling

Plexiglass laser drilling finds applications in various industries due to its precision and versatility. Here are some notable applications:

- Electronics: Laser-drilled plexiglass is used in the electronics industry for creating precise holes for components, connectors, and circuitry.

- Automotive: Laser drilling is employed in the automotive industry for perforating plexiglass components such as headlights, taillights, and interior panels.

- Medical Devices: Laser-drilled plexiglass is utilized in the manufacturing of medical devices, including surgical instruments, diagnostic equipment, and laboratory tools.

- Aerospace: Plexiglass laser drilling is used in the aerospace industry for creating holes in aircraft windows, cockpit displays, and interior componentssuch as control panels and cabin fixtures.

- Architecture and Design: Laser-drilled plexiglass is popular in architectural applications for creating decorative perforations in building facades, signage, and interior design elements.

- Art and Crafts: Artists and craftsmen utilize laser drilling to create intricate patterns and designs in plexiglass artwork, sculptures, and jewelry.

By harnessing the power of laser technology, manufacturers, designers, and artists can achieve intricate and flawless perforations in plexiglass. So, whether you’re looking to add functional holes or decorative patterns, consider plexiglass laser drilling for your next project.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.