Buyer Guide

Portable CNC Flame Plasma Cutting Machine

A CNC flame plasma cutting machine is a type of computer numerical control (CNC) machine used for cutting various types of metal using a combination of flame and plasma cutting technologies. The machine consists of a cutting table, a gantry system, a CNC controller, and a torch assembly.

The cutting table provides a stable surface for placing the metal workpiece to be cut. The gantry system, typically driven by motors and lead screws, moves the torch assembly along the X, Y, and Z axes to accurately position the torch for cutting.

Portable CNC Flame Plasma Cutting Machine

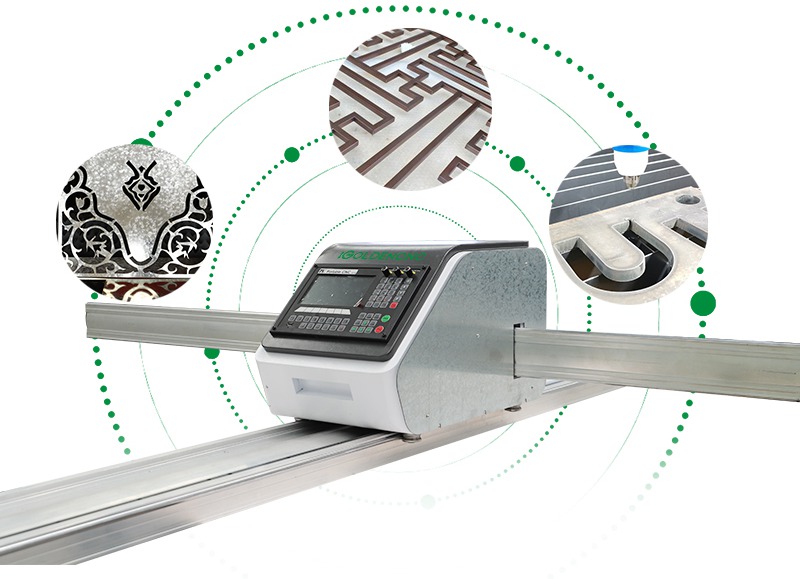

Portable CNC flame/plasma cutting machine consists of a CNC drive unit and two aluminum alloy rails, which makes the machine can be easily disassembled into some small parts to transport and quickly assembled to use. It’s ideal for small fabrication shops, maintenance and repair shops, trade schools, or for portable use within large facilities and construction sites.

Automated functions and a user-friendly CNC system has 45 different cutting path settings and any plane shape composed of beeline also can be programmed. Precision and solid guide rails and accuracy motion control makes the machine can precisely cut the shape as customers’ need.

Flame or plasma cutting mode can be choose on IGP1530 as customers’ need: Flame cutting mode is more suitable for cutting thick metal plate. But for the thin metal plate, plasma cutting mode is faster and the cutting edge is smoother. Flame torch and plasma torch can be exchanged very easily.

5ft X 10ft Portable CNC Flame Plasma Cutting Machine

The CNC controller is the brain of the machine and receives instructions from a computer or programming software. It interprets these instructions and controls the movement of the gantry system and the operation of the torch assembly. The controller also manages the cutting parameters, such as cutting speed, torch height, and gas flow.

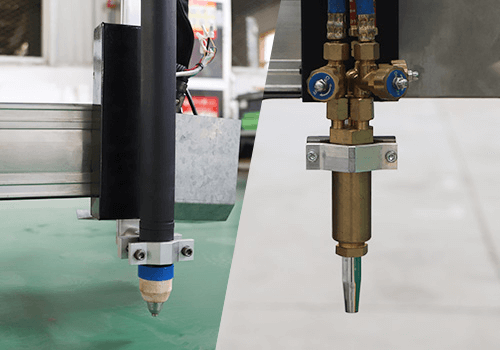

The torch assembly includes a plasma torch and a flame torch. The plasma torch generates a high-temperature plasma arc by passing a gas through a narrow nozzle and applying an electrical current to ionize the gas. This plasma arc can melt through metal, creating a precise and clean cut.

Torch Height Control

The flame torch, on the other hand, uses a mixture of fuel gas and oxygen to generate a high-temperature flame that can also cut through metal, albeit with a less precise and rougher cut compared to plasma cutting. The choice between plasma and flame cutting depends on the specific requirements of the cutting application. Plasma cutting is generally preferred for its ability to cut a wide range of metals, including stainless steel and aluminum, with high precision and speed. Flame cutting, on the other hand, is often used for thicker metals and materials that are not suitable for plasma cutting.

Cutting Speed and Productivity

CNC flame plasma cutting machines are known for their high cutting speeds, which significantly improve productivity compared to manual cutting methods. The combination of plasma and flame cutting technologies allows for efficient and rapid metal removal, enabling faster turnaround times for projects.

Precision and Cut Quality

Plasma cutting, in particular, offers excellent precision and cut quality. The focused plasma arc produces a narrow kerf width, resulting in minimal material wastage. The cut edges are generally clean and free from dross or burrs. Flame cutting, while not as precise as plasma cutting, is still suitable for applications where a high level of precision is not required.

Portable Plasma Cutting Machine Technical Parameter

| Model | iGP-P1530 |

| Working area | 1500*3000 |

| Control system | Fangling+Automatic height-adjustment |

| SigmaNest | Fangling CAM |

| Plasma power | HUAYUAN |

| Transmission | Rack |

| Longitudinal length of guide | 2300mm |

| Effective cutting length | 1500mm |

| Plasma cutting thickness | 3400mm |

| Flame cutting thickness | 3000mm |

| Machine running speed | 4000mm/min |

| Automatically raise the stroke | 0-120mm |

| Voltage | 380V±10% 220V±10% |

When considering purchasing or using a portable CNC plasma cutter, it’s essential to carefully evaluate your specific cutting needs, available space, budget, and the level of precision and performance required for your applications.

Portable cnc plasma cutter Features

- Can cut any plane shape parts, convenient and flexible, free to move, do not occupy a fixed site.

- Dynamic and static graphics display, intuitive and easy to learn, CAD files can be converted into program files on the computer, to achieve any graphics cutting, can also be directly programmed and set on the host;

- Integrated precision guide rail and unique moving mechanism design to ensure the accuracy of the whole system;

- Support flame cutting and plasma cutting two ways;

- Strong working stability, effective shielding plasma high-frequency interference;

- The system and arc voltage heightening device are integrated, which is more convenient and fast.

Plasma Cutting vs Flame Cutting?

Plasma Cutting vs Flame Cutting

- Plasma cutting can’t cut as thick material as Flame Cutting

- Plasma cutting imparts less heat into the profile, resulting in a significantly reduced Heat Affected Zone on the cut edges

- Plasma cutting has a cleaner cut edge

- Plasma cutting can cut smaller holes due to a lower kerf (width of material removed by the cutting process)

- Bevelled edges and 3 Dimensional sections can be processed by both processes (with the application of a 3rd axis or tilting head).

Plasma Cutting vs Laser Cutting

- Plasma cutting can cut the same and greater thicknesses of material than Laser Cutting

- Both can have comparable heat affected zones

Both can have a comparable cleanliness of cut edge - Plasma cutting can have a lower kerf (width of material removed by the cutting process

- Bevelled edges and 3 Dimensional sections can be processed by both processes (with the application of a 3rd axis or tilting head

- Plasma cutting is not affected by the reflective properties of a material, Laser Cutting is not possible with polished or highly reflective materials.

Installation of Portable CNC Plasma Cutting Machine:

When you are going to use iGP-P1530 to cutting the metal plate, follow these steps:

a. Fix the track by bolts beside the metal plate that needs to be cut.

b. Assemble the CNC drive unit on the track and then assemble the cross bar on the CNC drive unit. (Installation method can be seen in the video)

c. Assemble the THC (torch height control). (Installation method can be seen in the video)

d. Assemble the cutting torch (flame cutting torch or plasma cutting torch) on THC.

Pingback: Best Plasma Cutter for CNC Table - iGOLDENLASER