Buyer Guide

Fully Enclosure Metal Sheet and Pipe Laser Cutting Machine

Full-protection fiber laser cutting machine adopts a fully enclosed laser protective cover, is equipped with a special laser protective glass observation window, which is overall beautiful, safe and environmentally friendly, at the same time, it is equipped with a special exchange platform for fast exchange speed. It is a high-end special equipment for laser cutting of sheet metal, and it is the first choice for modern manufacturing enterprises.

Sheet and Pipe Laser Cutting Machine for Sale

Fully enclosed sheet metal protection is a necessary safety measure for laser cutting machines, which can ensure the safety of operators, reduce environmental pollution, and improve production efficiency and equipment reliability.

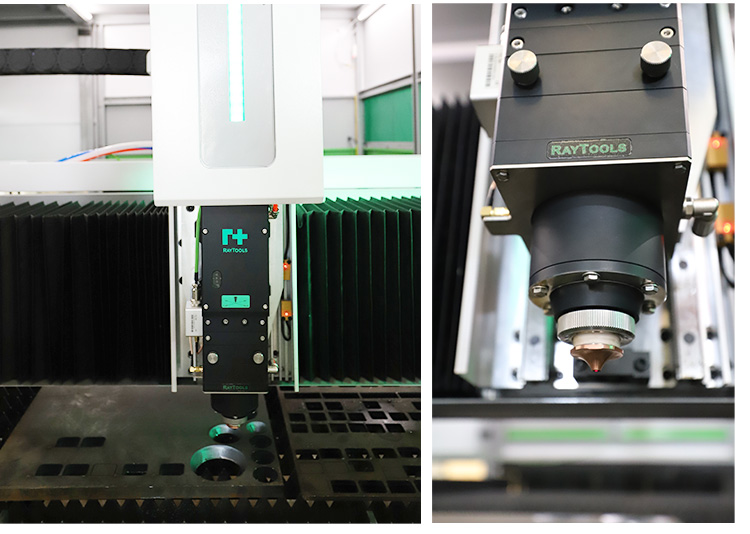

Laser Source:Metal sheet and pipe laser cutting machines use a high-powered laser source, typically a fiber laser, to generate a focused laser beam. Fiber lasers are commonly used due to their high energy efficiency, excellent beam quality, and ability to cut a wide range of metal materials.

Metal sheet and pipe laser cutting machines offer design flexibility, allowing for intricate cuts, precise contours, and complex shapes. The CAD software provides the freedom to create custom designs and nest multiple parts on a single sheet, optimizing material usage and reducing waste.

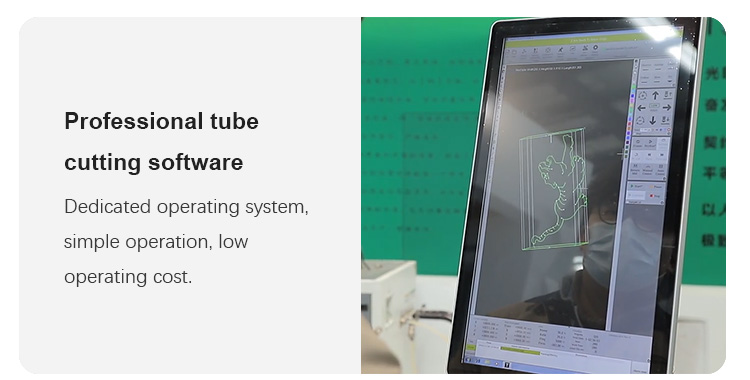

Metal sheet and pipe laser cutting machines are typically equipped with user-friendly software interfaces that allow operators to program cutting parameters, import design files, and control the cutting process. The software may also include features for optimizing cutting paths, managing material inventory, and generating reports.

Laser cutting machines can be integrated into automated systems, allowing for continuous and high-volume production. The CNC system ensures precise and repeatable cutting results, even for complex geometries or tight tolerances. Some machines also feature automatic loading and unloading systems to further enhance productivity.

The cutting process begins with the CAD (Computer-Aided Design) software, where the desired shapes or patterns are designed. The CAD data is then transferred to the CNC (Computer Numerical Control) system of the laser cutting machine. The machine’s controller guides the laser beam along the programmed paths, melting and vaporizing the metal material. An assist gas, such as oxygen or nitrogen, is typically used to blow away the molten metal and create a clean cut.

A metal sheet and pipe laser cutting machine is a versatile and efficient tool used for cutting both flat metal sheets and cylindrical metal pipes or tubes. It utilizes laser technology to create precise and clean cuts on various types of metals.

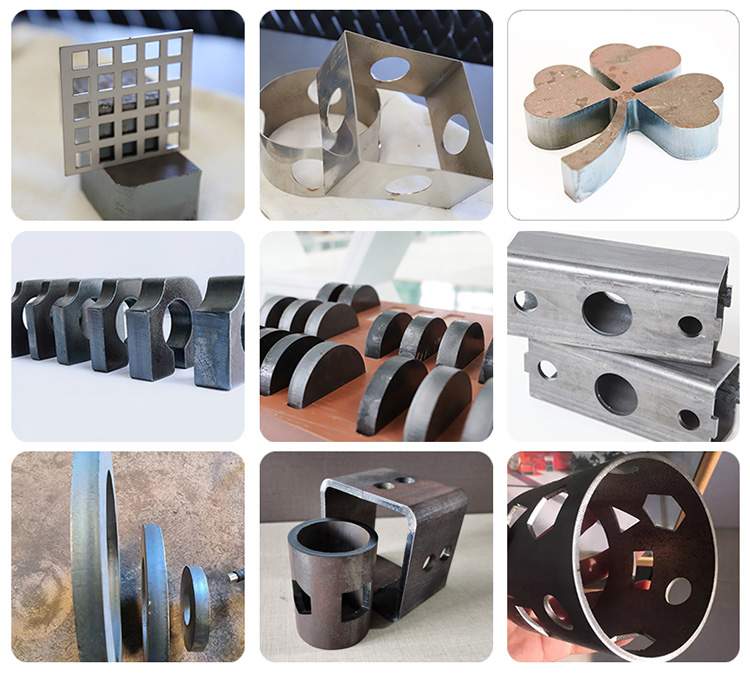

Laser Sheet Cutting: Metal sheet cutting is performed on a flat worktable where the metal sheet is securely clamped. The laser cutting machine moves the laser head and focuses the laser beam onto the sheet’s surface, following the programmed cutting path. The machine can cut various sheet metal materials, including stainless steel, carbon steel, aluminum, brass, copper, and more, with high precision and speed.

Laser Pipe Cutting: Metal pipe cutting is achieved using a specialized attachment or chuck that can hold and rotate the cylindrical pipe or tube. The laser cutting machine is equipped with a rotary axis, allowing it to cut along the pipe’s length or perform various angled cuts. Pipe cutting capabilities include straight cuts, bevel cuts, miter cuts, and even complex shapes or patterns. This process is commonly used in industries such as automotive, construction, furniture, and metal fabrication.

Metal Sheet and Pipe Laser Cutting Machine

This is a dual-use fiber laser cutting machine with an exchange platform. It can cut both metal sheets and tubes, realizing two functions in one machine. Besides, the two worktables also help increase the working efficiency by 50%.With an integrated design, it can cut both sheets and tubes to save purchase costs for users. It also has multifunctionality and high efficiency and can meet the cutting needs of different materials, improving production efficiency.

You will find full cover, exchange platform and different size metal tube and plate fiber laser machine to meet your needs. And about the fiber laser cutter price, fiber laser cutting machine price and tube laser cutting machine price, just send inquiry to us, and sales manager will give you feedback asap.

Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe

1. The machine is equipped with an exchanged double working platform. While working on one table, the other platform can load and unload the sheet workpiece;

2. Auto feeding model is driven by frequency conversation drive-down motor, high transmitting power and safety factor, enabling stepless speed adjustment for different operating frequencies;

3. Pipe cutting machine is specially designed for metal pipes, metal tubes;

4. Fully enclosed cover will keep you safe and healthy at work;

5. Imported high precision transmission device which is perfectly work with servo system, thus it can make sure cutting precision and efficiency;

6. Higher cutting quality and efficiency, cutting speed is up to 120m/min with appearance and beautiful cutting edge.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.