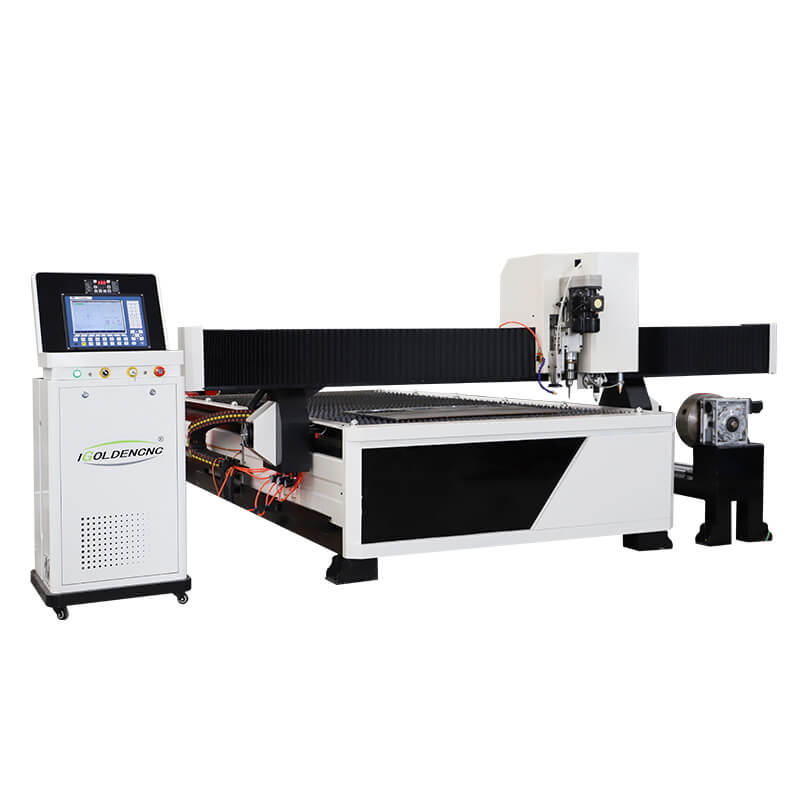

iGP-4A 1530

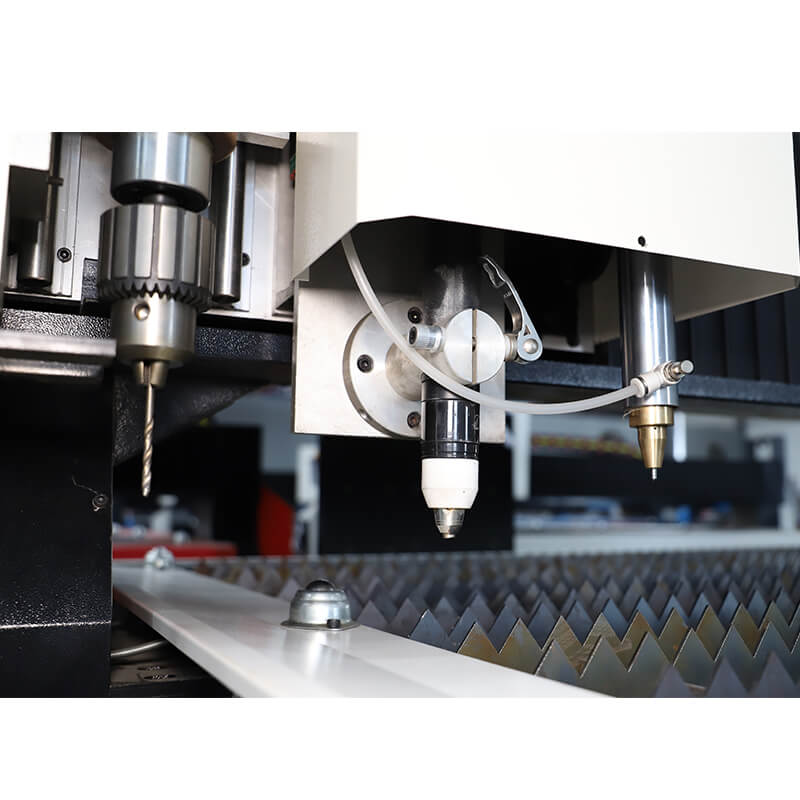

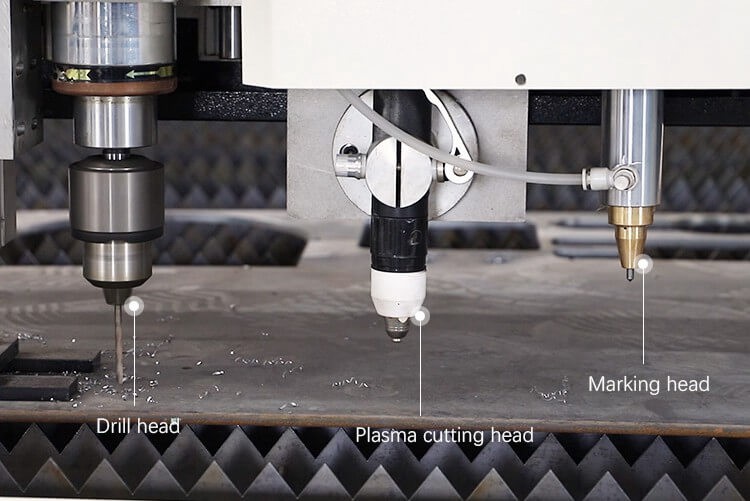

Plasma Cutting Machine With Marking and Drilling Heads

CNC table plasma cutting machine is an multi-purpose machine. It is very easy to deal with multi-processing needs! CNC plasma cutting machine can marking metal and oxy-fuel cutting!

CNC marking machine is able to achieve high quality CNC marking function for hard materials to draw lines marking. Compare with the laser,the cost,marking format,process control,and marking depth of IGP-1530 CNC table plasma cutting machine has a distinct advantage.Marking depth adjustable functions to draw lines, the greater the pressure,the depper draw lines。

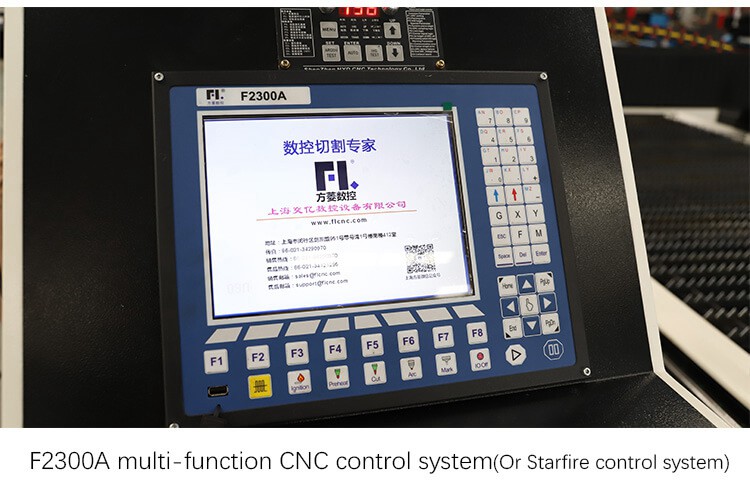

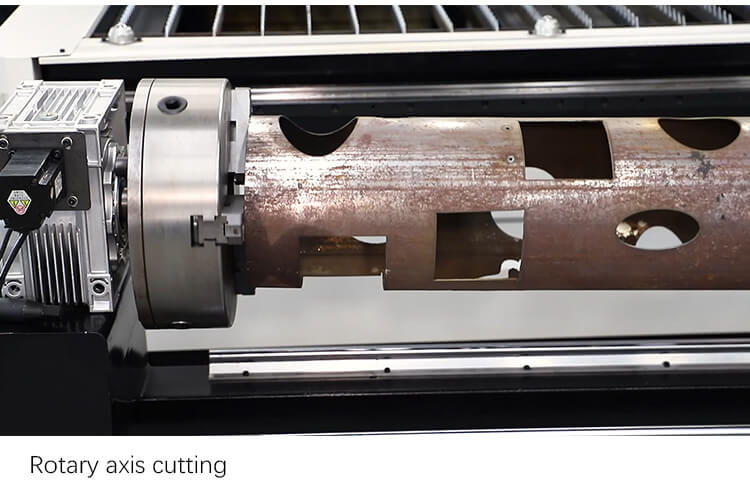

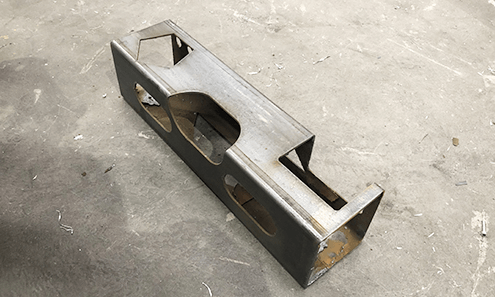

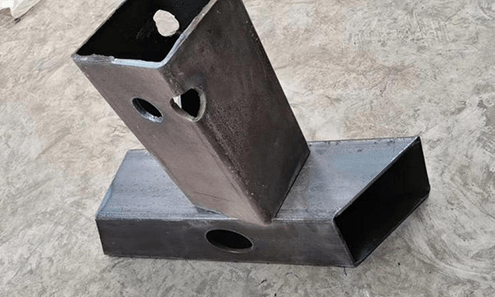

IGP-1530 Muti-function Plasma machine is a perfect solution for cutting sheet metal and tubing materials. It contains two parts: the main construction and the pipe cutter attachment. The former is a conventional table type plasma cutting machine, which is used to meet the cutting requirements of various metal plates. The pipe cutting attachment is a rotary system for cutting, notching, and piercing with square/round pipes. It comes with one plasma cutting torch in our default version. By using a servo motion system, it features excellent acceleration and deceleration. All-purpose cnc table plasma cutter for square/round tubing and sheet metal cutting for sale with a favorable cost now.

Diego Costa –

The metal CNC cutter for sale is a stable machine, the machine works about 8 hour a day, and the performance is very good.

Gaurav –

The tube I want to cut is about 200mm in diameter. Sometimes aluminum profile is also cut. A 3d plasma cutter is perfect for me. I have used this CNC plasma tube cutter to cut iron and stainless steel tubes, and the cutting speed is very fast.

Tristan –

We invested in this CNC plasma cutter for our construction projects, and it has exceeded our expectations. The machine handles both flat and tubular materials with ease, and the speed at which we can produce parts has boosted our overall productivity. Definitely worth the investment!

Clayton –

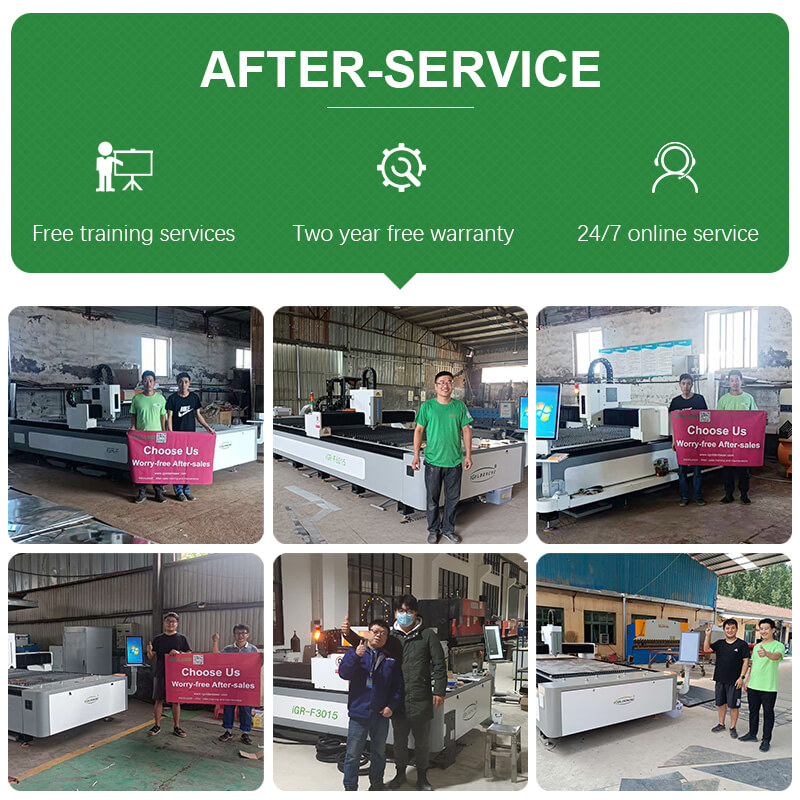

I’ve tried several plasma cutters over the years, but this one stands out. The adjustable torch height ensures that I get consistent results, even with varying material thicknesses. Plus, the customer support has been fantastic. They helped us get set up quickly!

Dannielle –

This machine has transformed our shop. It’s easy to use, and the software integration is seamless. We can cut both sheet metal and tubes effortlessly, which has opened up new project possibilities for us. Highly recommend for anyone in the fabrication industry!

Genie –

We recently upgraded to this CNC plasma cutter, and the difference has been remarkable. The cutting speed is incredible, and the precision is unmatched. We’ve been able to reduce our production time significantly while maintaining high-quality cuts. The exchange worktable is a game changer for our workflow!

Davida –

As a small business owner, I need equipment that delivers quality without breaking the bank. This plasma cutter is both affordable and efficient. The cuts are clean, and the machine is user-friendly, which is great for my team. I’m very satisfied with my purchase!