No products in the cart.

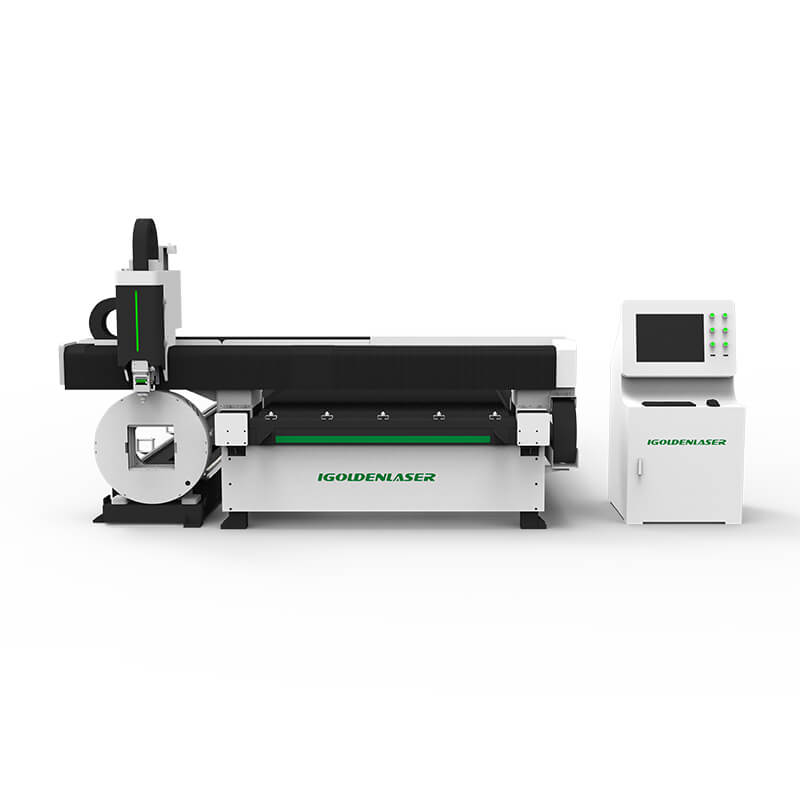

iGR-L(T)

Sheet Plus Tube Laser Cutting Machine

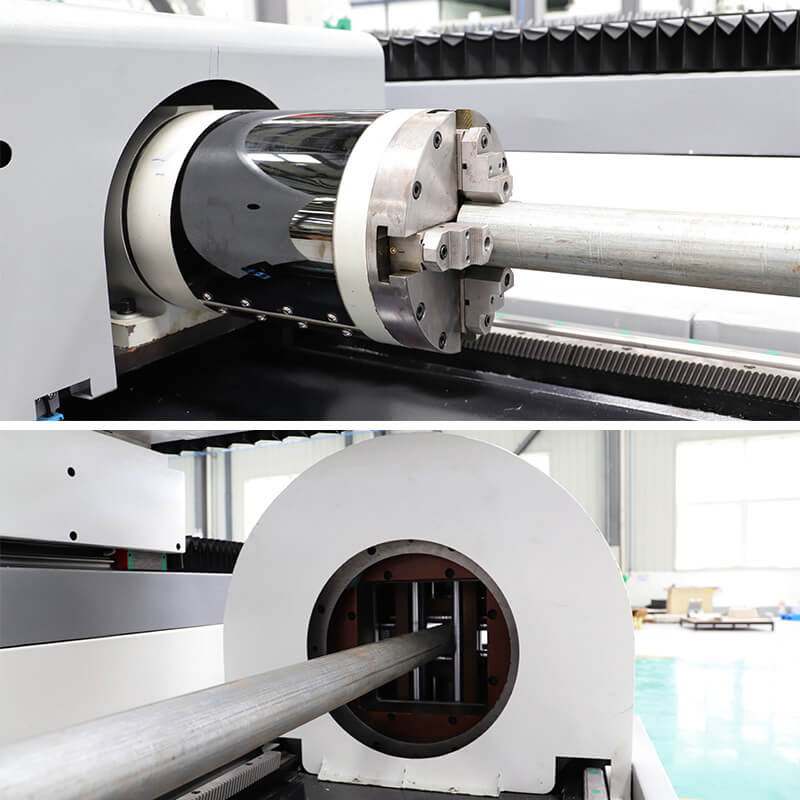

The sheet metal & tube laser cutting machine is an improved version of the iGR-L series capable of cutting most sheet metals, metal plates, metal tubes, and metal pipes. Saving more than half the cost of purchasing two types of machines, doubling production efficiency, and saving more than half the workshop space.

iGR-F(+T) tube and plate sheet metal laser cutting machine is for high-speed, high-quality cutting of various types of sheet metal and cutting of different cross-section metal pipes and profiles specially designed. This series of devices are for small and medium enterprises specially designed. Reliable components from the world’s leading companies, excellent design solutions, and assembly quality make this model a sharp contrast with competitor manufacturers of similar equipment. This model laser cutting machine can be equipped with different power laser sources; the power range is 1000 W to 10 KW.

Reviews

There are no reviews yet.