Buyer Guide

Square & Round Tube CNC Plasma Cutting Machine

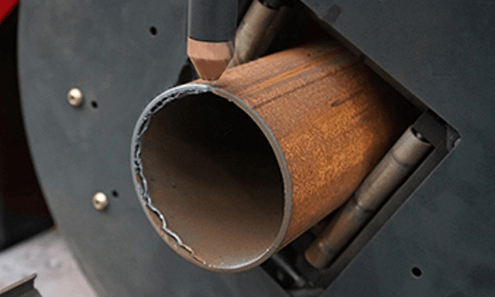

Plasma cutting machine is a machine that processes metal materials with the help of plasma cutting technology. Fast cutting speed, small deformation, smooth cutting surface, small thermal deformation, almost no heat affected zone, can be cut square tube, round tube;Standard equipped with two modes of plasma cutting and flame cutting, integrated structure, bilateral drive, fast cutting speed, low inertia and stable operation.

Tube CNC Plasma Cutting Machine

Plasma cutting machine is a machine that processes metal materials with the help of plasma cutting technology. Fast cutting speed, small deformation, smooth cutting surface, small thermal deformation, almost no heat affected zone, can be cut square tube, round tube;

The Tube CNC Plasma Cutting Machine is a state-of-the-art equipment specifically developed to meet the demands of tube cutting in various industries. It combines the capabilities of CNC technology and plasma cutting to deliver high-quality and precise cuts on a wide range of tube materials, including steel, stainless steel, aluminum, and more. With advanced automation features, it offers increased productivity and efficiency, reducing manual labor and human errors in the cutting process.

Can flame cut low carbon steel, can also plasma cut high carbon steel, stainless steel, aluminum, copper and other non-ferrous metals; Can be customized according to customers; Widely used in machinery, automobile, shipbuilding, petrochemical, military, metallurgy, aerospace, boiler pressure vessel, locomotive and other industries.

Plasma Cutting System

The Tube CNC Plasma Cutting Machine incorporates a high-performance plasma cutting system. Plasma cutting uses an ionized gas jet to melt and sever the metal, resulting in clean, smooth, and precise cuts. This technology ensures minimal heat-affected zones and distortion, preserving the structural integrity of the tubes.

The Tube CNC Plasma Cutting Machine is equipped with a user-friendly control interface that provides real-time monitoring and control over the cutting process. Operators can adjust cutting parameters, track progress, and make necessary modifications on the fly, ensuring optimal results.

Automatic Tube Feeding and Rotation

The machine features an automatic tube feeding and rotation system, eliminating the need for manual handling and repositioning of tubes. This automation enhances efficiency and reduces operator fatigue, enabling continuous and uninterrupted cutting operations.

TECHNICAL PARAMETER

| Model | iGP-S |

| Pipe size | 150*150*8000mm |

| Bed | Heavy duty pipe welded bed |

| Reduction | Shimpo |

| Servo motor | Japan Yaskawa |

| Driving system | X,Z axis ,Push axis 400w,Rotary axis 750w Pneumatic Cutting Chuck , dual driver , two chucks can work at same time , to confirm cutting precision |

| Control system | Fangling |

| Plasma power | Huayuan/Hypon |

| Transmission model | X,Y reducer,z ball screw |

| Transmission | Anti-friction Gear-wheel |

| Cutting speed | 15-20m/min |

| Cutting thickness | Max 10mm |

| Process precision | ±0.3mm |

| Repeat positioning accuracy | ±0.05mm |

| Input voltage | 3 phase 380V for power source,single phase,220V for machine |

| Gross Power | 20KW |

It is applied in all types of machinery, metal structure manufacturing, repair and installation service, sheet metal fabrication, hole drilling, digging and patching, beveling and more metal cutting projects & plans.

Application of Tube CNC Plasma Cutting Machine

Applicable Materials of plasma pipe cutting machine

Cutting stainless steel, carbon steel, mild steel, iron . Cutting round pipe , square pipe , angle steel , steel channels etc .

Applicable Industries of plasma pipe cutting machine

he Tube CNC Plasma Cutting Machine finds applications in various industries, including but not limited to: Metal fabrication and manufacturing Automotive and aerospace industries Construction and infrastructure development Oil and gas exploration Shipbuilding and marine engineering Furniture and interior design HVAC (Heating, Ventilation, and Air Conditioning) systems.

The field of CNC plasma cutting technology continues to evolve, and future developments may bring further advancements to the Tube CNC Plasma Cutting Machine. These could include improved automation capabilities, enhanced cutting speeds, integration with Internet of Things (IoT) systems for remote monitoring and control, and the incorporation of artificial intelligence algorithms for optimized cutting strategies.

CNC Plasma Square Tube Cutter Features

- Used for cutting metal square pipe. The LCD operation panel can prompt a variety of operation modes, making the operation more convenient and simple, and can cut the metal into various complex shapes;

- Frame adopts thick wall section steel welded bed, more solid and stable;

- High precision Taiwan square guide rail, high efficiency rack and pinion, carburized and quenched surface;

- low noise, stable and accurate coordinate movement;

- The drive system adopts Japanese Yaskawa servo type to ensure the whole machine in a wider speed range, short acceleration time and stable operation;

- The torch height controller can automatically adjust the optimal cutting distance to ensure high precision workpiece cutting.

Tube CNC Plasma Cutting Machine is a highly advanced and versatile solution for precise tube cutting. With its advanced features, automation capabilities, and potential for customization, this machine offers numerous benefits to industries requiring accurate and efficient tube cutting operations.

What Are The Advantages of Plasma Cutting?

It is an efficient metal cutting method for sheet metal and metal tubes, which has made it to be widely used in many different industries.

You can get benefits from 10 best advantages with fast cuts, ease of use, lower cost, safe to use, multi-tasking, expanded versatility, wide range of material and thickness, eliminated plate warping, raised inside piercing speed, and diminished dross.

Compared with traditional manual & semi-automatic metal cutter, automatic computer-controlled metal cutting system is an integration of quality improvement and cost-efficiency. CNC metal cutters include computerized numerically controlled plasma, flame, water plasma and laser cutting machine. It performs automatic, full-time, high-quality, high-utilization and efficient cutting according to the CNC nesting software.

In industrial production, metal thermal cutting generally includes gas, plasma, and laser cutting. Compared with gas cut, plasma cut has a wider cutting range and higher efficiency. The fine plasma cut system is close to the quality of laser system, but the cost is much lower than that of laser.

It has shown great advantages in saving materials and improving labor productivity. This has promoted it from manual or semi-automatic to numerical control, and has become one of the main directions of the development of numerical control cutting technology.

1. It can cut thicker metals, such as stainless steel, aluminum and its alloys, copper and its alloys, cast iron and other metal materials. You can also use cutting torch to cut insulating materials and non-metallic materials with thickness of more than 150mm.

2. The speed is fast, and the production efficiency is high, especially when working with thin metals with high power, the production efficiency is improved more significantly.

3. The cutting quality is high, the slit is smooth and flat, the incision is narrow, and the heat-affected zone and deformation are smaller than other tools.

4. Low cost, due to the high speed, the use of cheap gas such as nitrogen requires less raw materials and labor than other methods to cut the same material.

Pingback: CNC Plasma Tube Cutting Machine