Buyer Guide

Advantage Of Stainless Steel Laser Welding Machine

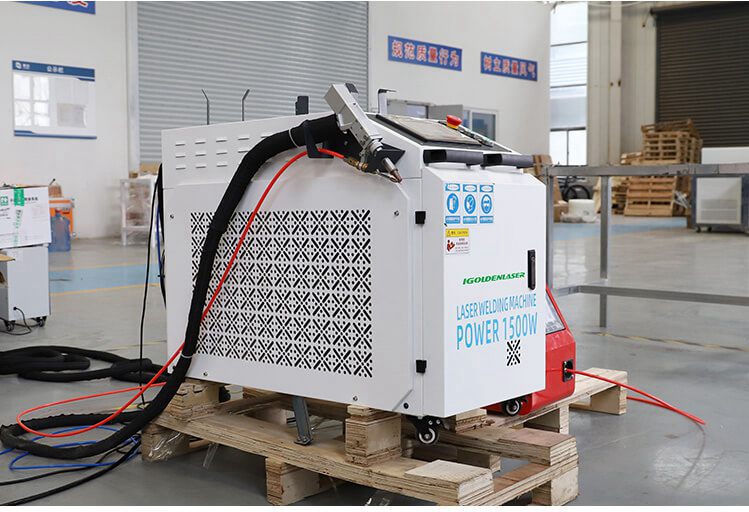

Stainless steel laser welding machine is a new welding method, which is widely used in precision processing industries such as automobile industry, metal processing industry, ship and aircraft manufacturing, Furniture and kitchenware processing, electronic products processing, metal parts maintenance, etc. It is mainly aimed at the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, overlap welding and seal welding. 1500w laser welder for titanium alloy, galvanized sheet, aluminum material and copper material can accurately weld

This process overturns the working mode of the traditional hand laser welder. It has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can be perfect for welding thin stainless steel plates, iron plates, galvanized plates and other metal materials. It replaces traditional argon arc welding of stainless steel plate, iron plate, aluminum plate and other metal materials welding.

Advantage of stainless steel laser welding machine :

(1) The amount of heat input can be minimized, the metallographic range of the heat affected zone is small, and the deformation due to heat conduction is also the lowest.

(2) The welding process parameters of 32mm plate thickness single pass welding have been qualified, which can reduce the time required for thick plate welding and even eliminate the use of filler metal.

(3) There is no need to use electrodes, no concerns about electrode contamination or damage. And because it is not a contact welding process, the wear and deformation of the machine can be minimized.

(4) The laser beam is easy to focus, align, and guided by the optical instrument. It can be placed at an appropriate distance from the workpiece and can be redirected between the implements or obstacles around the workpiece. Other welding methods are subject to the above space limitations. Can’t play.

(5) The workpiece can be placed in a closed space (with vacuum or internal gas environment under control).

(6) The laser beam can be focused on a small area to weld small and closely spaced parts.

(7) The range of weldable materials is large, and various heterogeneous materials can be joined to each other.

(8) It is easy to automate high-speed welding, and it can also be controlled by digital or computer.

(9) When welding thin materials or thin-diameter wires, it is not easy to remelt like arc welding.

(10) It is not affected by the magnetic field (easy for arc welding and electron beam welding) and can accurately align the weldment.

(11) Two metals that can be soldered with different physical properties (such as different resistances).

(12) No vacuum is required and X-ray protection is not required.

(13) If the hole is welded, the width of the weld bead can reach 10:1.(14) The switching device can transmit the laser beam to a plurality of workstations.

Why handheld laser welding machines are expensive

The hand-held laser welding machine is expensive because it is balanced with its own value. Handheld laser welding machine as a new technology equipment, the accessories used are naturally not bad, we mainly talk about its two main components:

Imported well-known brand-single-mode continuous fiber laser, the system is highly integrated, maintenance-free, and highly reliable. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, fine welding and other applications.

Handheld metal laser welding machine

The well-known brand double pendulum welding gun, the gun head can be delivered with a wire fixing frame (detachable) 10 meters long optical fiber cable to connect the cabinet and the welding gun, the welding range is expanded, and it breaks the traditional fixed workbench welding mode.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.