Buyer Guide

Stainless Steel Pipe Laser Cutting Machine

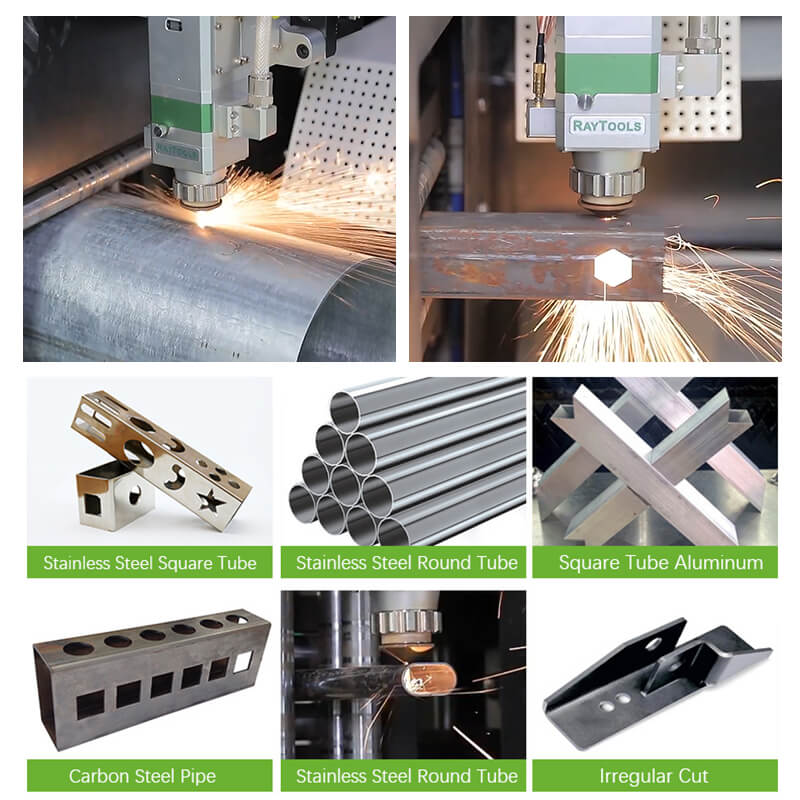

Tube Laser Cutting Machine For Stainless Steel

Stainless steel is a group of iron-based alloys that contain a minimum of approximately 11% chromium. Stainless steel pipe components are widely used in sanitary fittings, kitchenware, appliance brackets, surgical instruments, food manufacturing, and other industries. Thanks to high precision, high speed, and diversified functions, more and more manufacturers choose the automatic stainless steel circle cutting machine and tube laser cutting machine. As one of the leading stainless steel laser cutting machine manufacturers in China, IGolden laser provides the best quality CNC stainless steel pipe cutting machine/cutter at a competitive price. As one of the professional stainless steel laser cutting machine manufacturers, our company manufactures the machines, for example, small CNC steel laser cutter, whic can provide good stainless steel laser cutting services to meet the requirements of the production.

What are the advantages of stainless steel laser cutting machines compared with traditional saw blades?

CNC Tube Cutting Technology for Metal Pipes

With the rapid growth of metal pipe production and consumption in China, pipe laser cutting equipment is rapidly popularizing. The rapid growth in demand for CNC cutting talents and laser tube cutting technology also highlights the serious shortage of laser tube cutting equipment, CNC tube cutting technology talents and processes. As a result, the cutting efficiency is low, the cutting quality is poor, and the pipe is wasted seriously.

This article will analyze the main problems of CNC tube cutting technology, and provide targeted solutions.

1. Full-stroke automated laser cutting and blanking of large-length metal pipes

The process requirements of full-stroke automatic laser cutting and blanking of large-length metal pipes: a unique dual-drive pneumatic chuck rotating mechanism (active shaft W, driven shaft W1) is adopted in the mechanical structure, and the pneumatic chuck rotating mechanism of the left driving shaft W is fixed to clamp the pipes, which are clamped and cut through the X, Y, and W movements of the machine tool. The rotating mechanism of W1 pneumatic chuck on the right driven shaft can move along the axis of the workpiece with the worktable, which can achieve large full-stroke automated laser cutting and blanking of length metal pipes.

2. CNC tube cutting technology

CNC tube cutting is a large-scale, high-efficiency and high-quality pipe cutting production method, with CNC cutting system as its core. At present, the quality problems existing in the laser tube cutting process such as overburning of the cutting point and corners of the part, inclined cutting surface, and deformation or inability to close when cutting round parts directly lead to serious waste of the tube and low cutting production efficiency.

CNC tube cutting technology is the cutting control software of the index control system that provides advanced cutting technology and rich cutting experience, so that cutting operators can achieve high-quality and high-efficiency CNC cutting through the proficient use of the control system.

3. Professional CNC tube cutting and nesting technology

Due to the high cutting efficiency of CNC tube cutting technology, programming nesting is more complicated. If used improperly, it will cause pipe waste and low cutting efficiency. We use professional pipe cutting and nesting software to pre-program drawing, nesting, and blanking on the computer to generate NC cutting programs, and then perform full-stroke automated laser cutting and blanking of large-length metal pipes. Professional pipe nesting software is the basis and prerequisite for realizing large-volume, high-efficiency and high-quality cutting production of CNC pipe cutting machines.

4. CNC tube cutting process

When the pipe is cut (especially for the square pipe with small pipe diameter), the molten slag adheres to the inner wall of the pipe, and most of the heat generated by the cutting is absorbed by the workpiece. High cutting density will lead to the overheat of the pipe and the overburning of corners and square pipes, seriously affecting the quality of the incision.

In order to slove such problems, you can try:

(1) The laser cutting head with a height sensing follow-up system can ensure that the height of the cutting nozzle and the surface of the workpiece remains unchanged (the focus remains unchanged) during the cutting process, so that the cutting effect will not be affected by the change of the workpiece surface;

(2) The method of increasing the oxygen pressure (6-8Mpa);

(3) Improve sharp corner synthesis speed through software.

The above method can solve the problems of overburning and slagging in CNC pipe cutting.

The CNC laser cutting technology of metal pipes is in the process of rapid development and continuous improvement. With the continuous update and development of computer technology, mechanical structure, cutting technology and optimization algorithms, CNC pipe cutting technology will more prominently show its intelligence, speed as well as optimized cutting technology and skills, providing technical guarantee for the efficient and high-quality cutting of the laser tube cutting machine, as well as the saving of tubes and energy consumption.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.