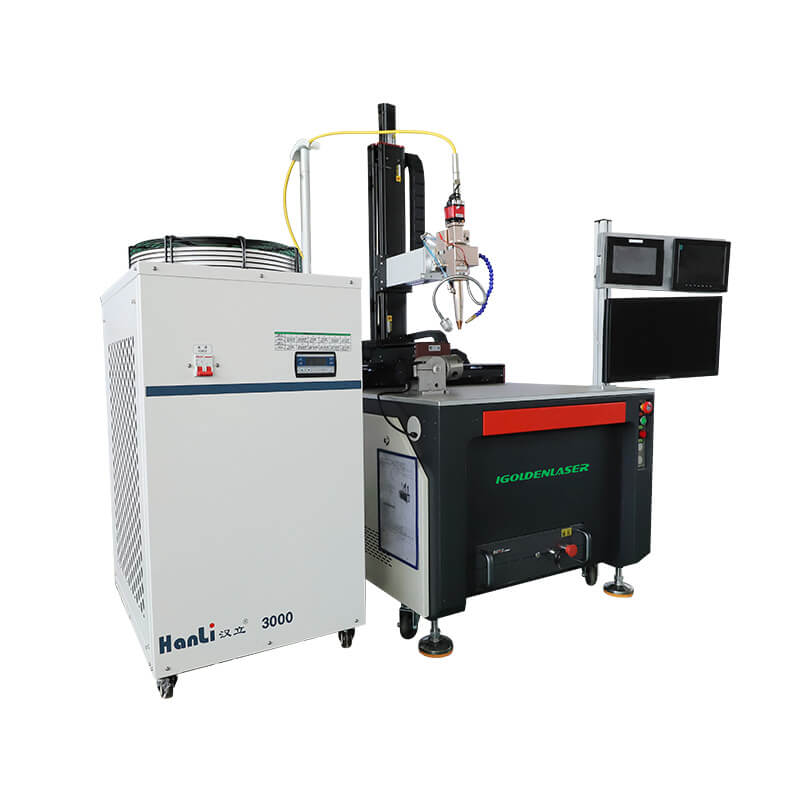

IGCL-AW(1000w-3000w)

Platform Automatic Welding Machine

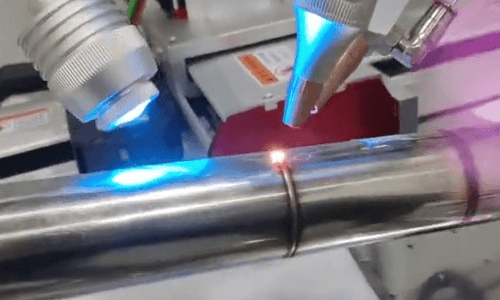

Automated platform laser welding machine, is an automatic welding solution. With fixture and automatic programming control, just put the product into the fixture can realize automatic welding, can achieve similar products in large quantities, fast, consistent welding requirements, very suitable for the same kind of mass automatic production of micro and small workpiece welding.

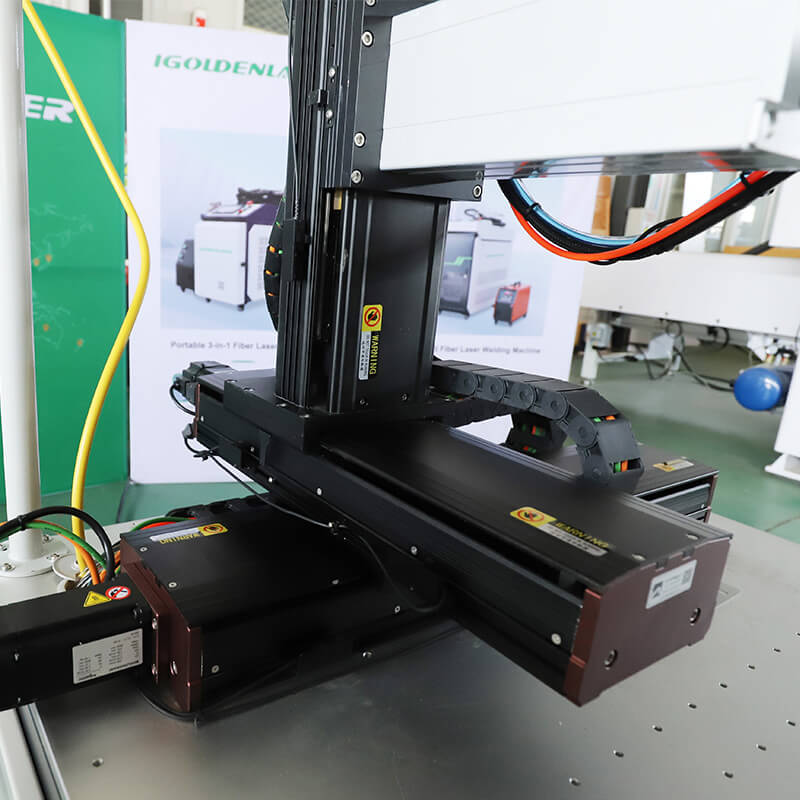

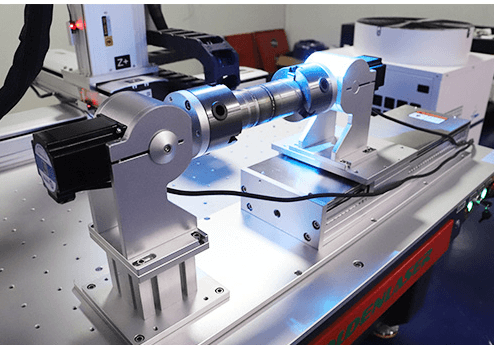

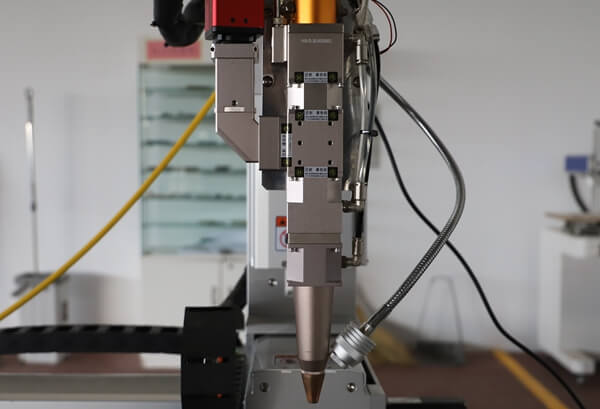

Multi-axis linkage work, can easily achieve a variety of angles, a variety of positions of welding, welding, seam welding. Precision welding plane, circumference, linear products and non-standard customized production lines, especially thin stainless steel plate, iron plate, aluminum plate and other metal materials, welding has the characteristics of fast welding speed, good surface effect, deep penetration, small heat affected area.

Automated Laser welding machine (Laser Power:1000W, 1500W, 2000W,3000w)

Reviews

There are no reviews yet.