IGP-P

Portable CNC Plasma Cutting Machine

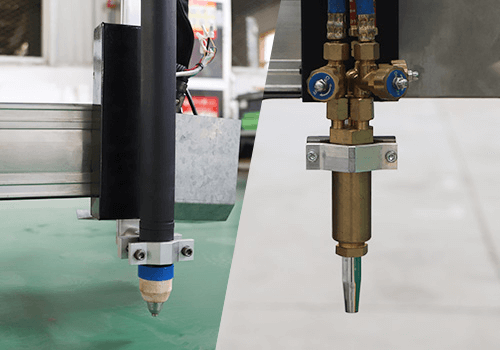

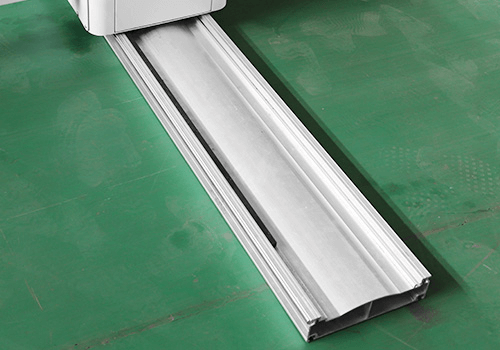

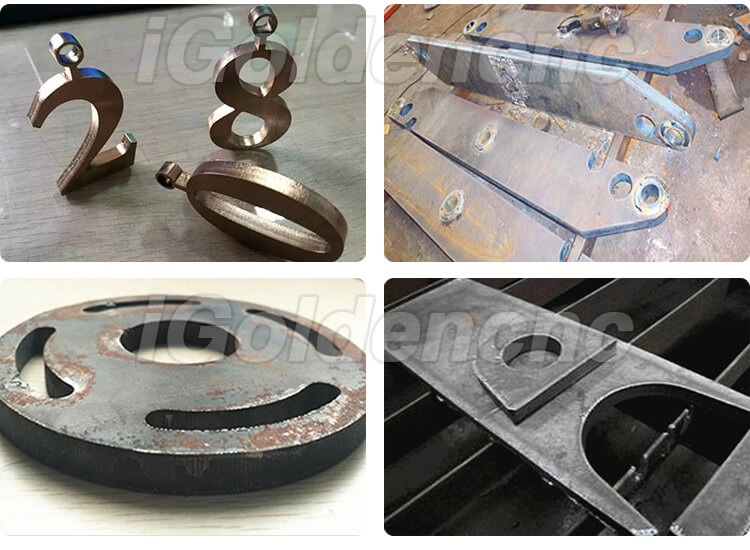

The portable CNC cutting machine is an ideal upgrade product to replace handheld flame-cutting equipment, handheld plasma cutting devices, profiling cutting machines and semi-automatic cutting carts. The use is as flexible and convenient as the cutting trolley, and it can be moved at will without occupying a fixed site. It is a CNC equipment specially used for sheet metal blanking.

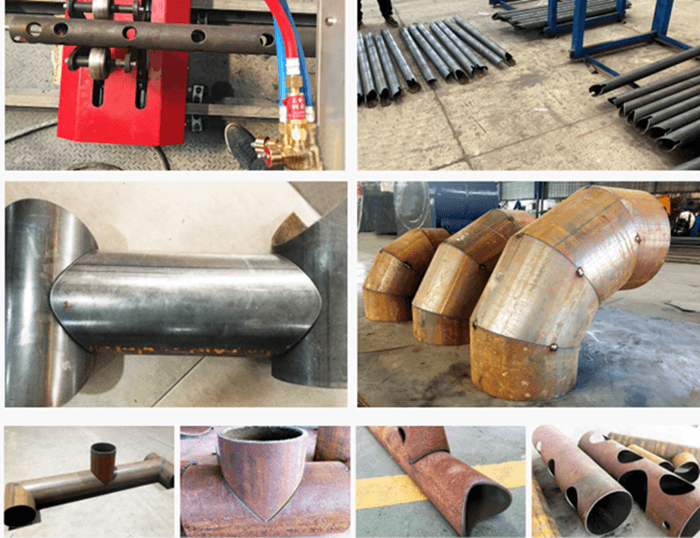

The iGP-P series portable CNC plasma cutter for sale, which is popular among professional users, is suitable for large sheet metal processors and users whose processing sites are not fixed.It can be directly placed on the plate to be cut to achieve cutting, so that the work efficiency is increased by more than 3-7 times, while saving the cost of cutting, reducing secondary processing, and improving production efficiency.

kpauls –

The CNC plasma tables for sale is good enough for me. The table size is 5×10, enough for me!

Fernandez –

I wanted to buy a cheap plasma cutter, but my friend advised me not to buy a cheap plasma cutter, because the cheap plasma cutter is easy to break.