Buyer Guide

Thin Plate Stainless Steel Fiber Laser Welding Machine

Once upon a time, operators all had a manual arc welding equipment. When welding, it is hard to weld a workpiece with beautiful appearance. Until the advent of laser welding machines, this situation was changed. With the development of automation in the electrical machinery, automotive and other industries, laser welding technology is being applied in more and more industries.

Stainless Steel Fiber Laser Welding Machine

Fiber laser welding machines provide high precision and accuracy in welding stainless steel materials. They offer a focused laser beam that can achieve fine weld seams, making them suitable for applications where precision is essential. Additionally, fiber lasers can operate at high speeds, resulting in faster welding processes.

Stainless steel fiber laser welding machines can weld various types and thicknesses of stainless steel materials. They are capable of welding thin sheets as well as thick plates, making them suitable for a wide range of industrial applications.

Thin plate stainless steel has a small thermal conductivity of about one-third that of ordinary low carbon steel. Therefore, during welding, once the thin plate stainless steel is locally heated or cooled, it will bear uneven stress and strain. The fiber laser welding machine solves this problem very well. It transmits a laser beam to the fiber and performs a method of welding after a series of treatments.

Laser welding uses high-energy laser pulses to locally heat the material in tiny areas. The energy of the laser radiation diffuses into the interior of the material by heat conduction, then melting the material to form a specific molten pool for welding. The spot of the fiber laser beam is very small, which focus up to 10 microns. Because it is a continuous wave laser, it meets the high power density required for batch and continuous welding.

Compared with the arc welding machine, fiber laser welding machine has the following merits:

1. Laser welding has a high energy density.When the high power laser beam is focused, the focal spot diameter is small. Therefore, the power density is very high and can up to 105~108W/cm2.

2. Small heat affected zone, little deformation of the workpiece. Laser welding heating and cooling speed is extremely high, its crystallization speed is several times higher than that of general fusion welding. There is no need for subsequent processing.

3. Continuous wave laser. Meet the requirements of high power density when batch and continuous welding.

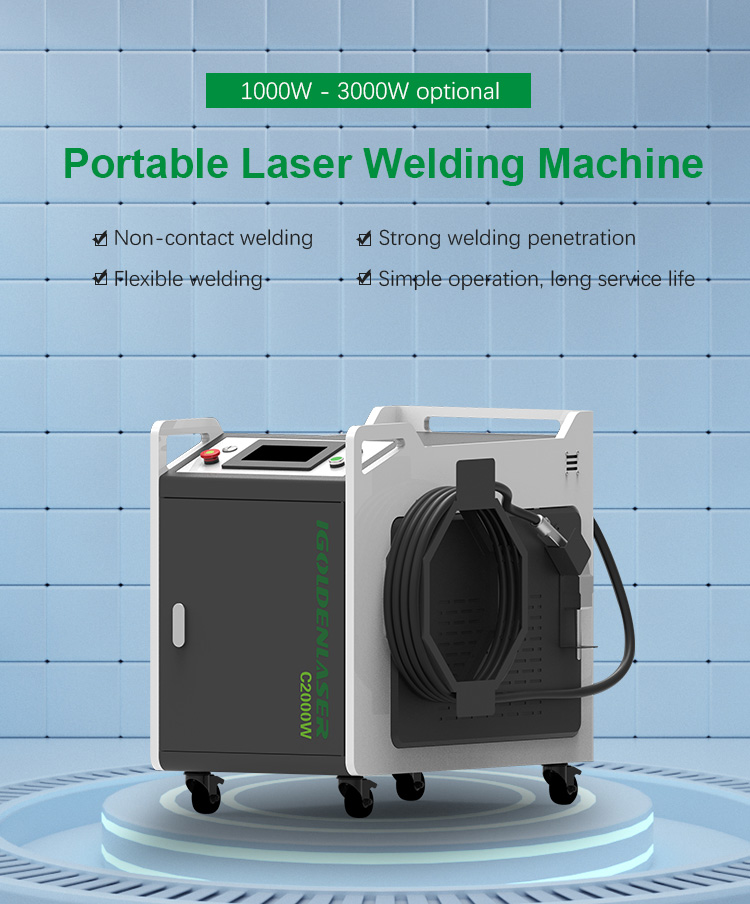

Fiber laser welding machine As our hot-selling product, iGWL is the fiber laser welding machine that is used to weld metal plates and metal tubes. The power is 1000w and 3000w. The performance in welding thin metal is good.More details, welcome to contact us.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.