Laser Knowledge

What Can Robotic Laser Welding be Applied To?

In the field of intelligent robots, the development of laser welding robots has a long history. Welding robot is a robot engaged in welding work. It is a versatile, programmable control manipulator, commonly used in the field of industrial automation, and is a key link in industrial intelligence.

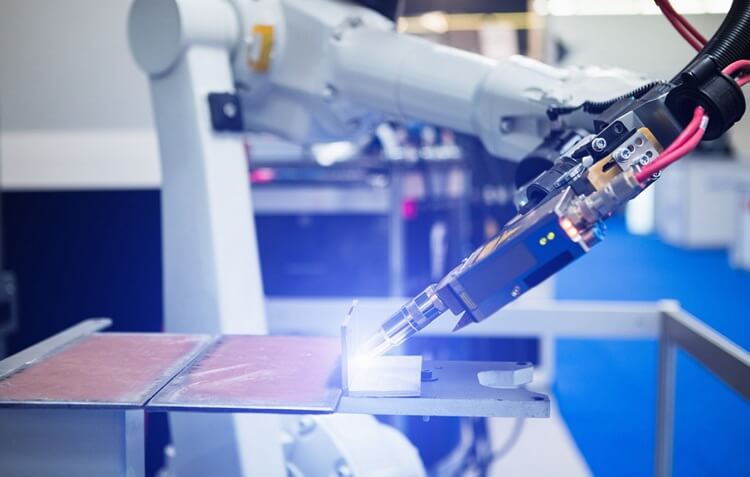

Robotic Laser Welding

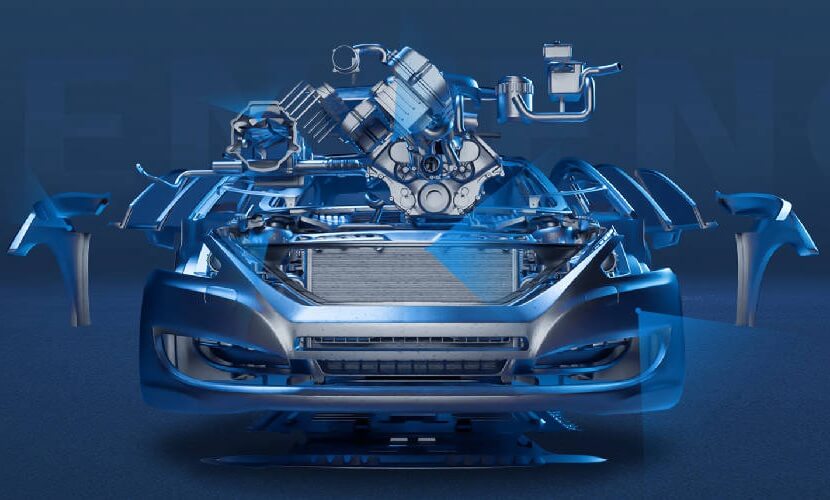

The robot laser welding machine is composed of a dedicated fiber laser head, a high-precision capacitance tracking system, a fiber laser and an industrial robot system. It is an advanced equipment for flexible welding of metal sheets of different thicknesses from multiple angles and multiple directions. It is widely used in metal processing, machinery manufacturing and auto parts manufacturing that have processing requirements for three-dimensional workpieces.

Laser welding uses a high-energy density laser beam as a heat source to locally heat the material in a small area to melt the material to form a specific molten pool, so as to achieve the welding effect. Laser welding is mainly used for welding thin-walled materials, precision parts, etc. It can realize spot welding, splicing welding, sealing welding, lap welding, etc.

The combination of laser welding and robots has the advantages of automation, intelligence, and high flexibility, and can be used for welding complex surface materials.

laser robotic welding systems

Robot laser welding machine is a type of industrial equipment that combines robotic technology with laser welding capabilities. Laser welding is a welding process that uses a laser beam to melt and join metals together. When integrated with a robotic system, it allows for precision and automation in the welding process.

Robot laser welding systems provide high precision and accuracy in the welding process. The focused laser beam allows for fine control over the welding parameters, resulting in clean and precise welds.

Automation with robots can improve workplace safety by reducing the need for human operators to be in close proximity to the welding process. This can be especially beneficial in hazardous environments.Robot laser welding machines can be equipped with sensors and vision systems for quality control purposes. These systems can monitor the welding process in real-time, ensuring that the welds meet the specified standards.

Optional laser power 1500W-3000W; support customization.

Robotic Laser Welding Applications

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.