Laser Cleaning Machine

A laser cleaning machine is a highly advanced piece of equipment that uses laser technology to clean various surfaces.

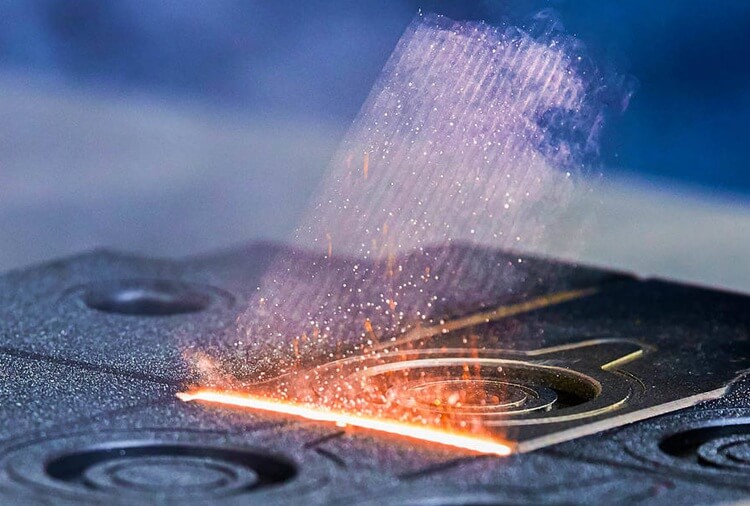

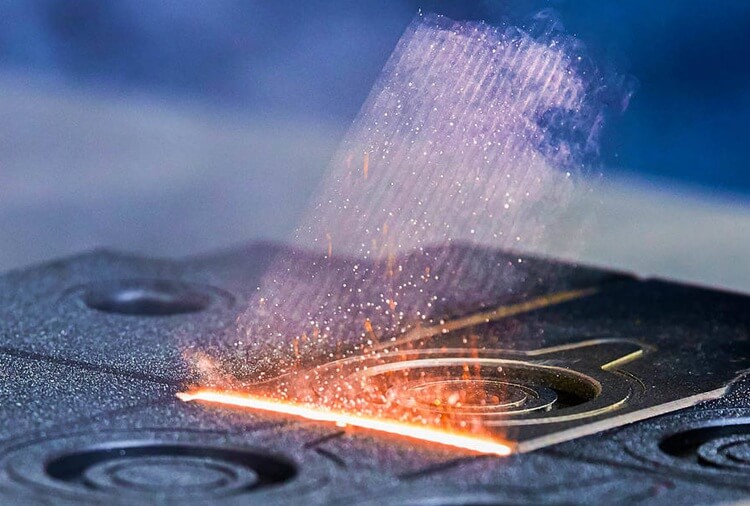

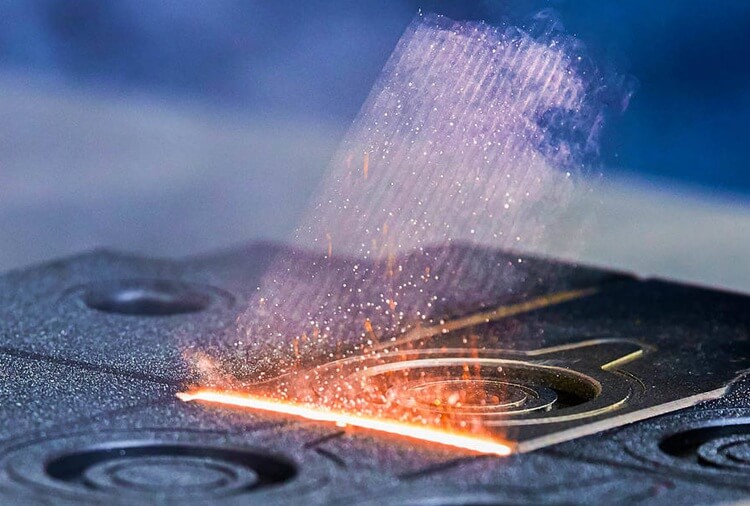

It works by emitting a high-intensity laser beam that is focused on the surface to be cleaned. The laser energy interacts with the contaminants on the surface, such as rust, paint, oil, dirt, and oxides. The heat generated by the laser causes the contaminants to vaporize, sublime, or disintegrate, leaving the surface clean and free of impurities.

Laser cleaning machines offer several advantages. Firstly, they are highly precise and can target specific areas without damaging the underlying substrate. This makes them suitable for cleaning delicate or sensitive materials. Secondly, they are environmentally friendly as they do not use any chemicals or solvents, reducing the risk of pollution. Thirdly, they are efficient and can clean large areas quickly, saving time and labor costs.

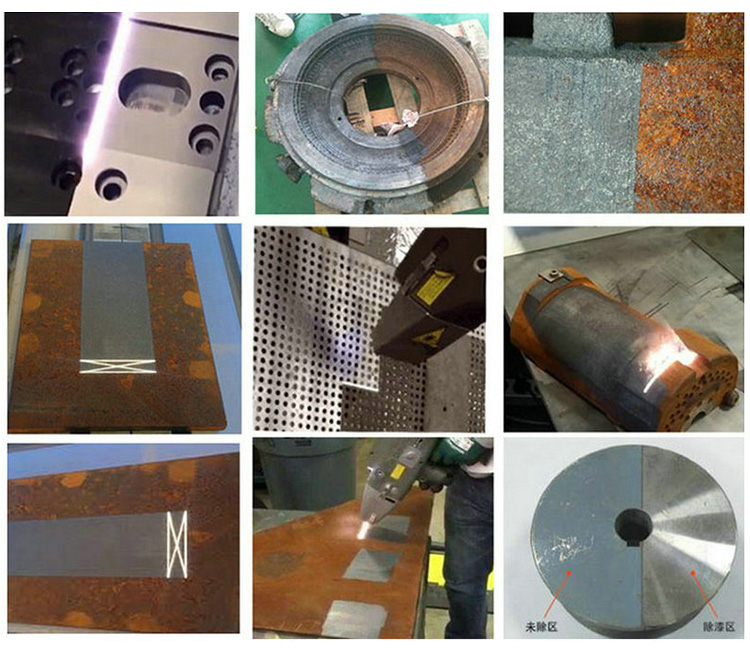

These machines are widely used in industries such as automotive, aerospace, shipbuilding, metal processing, and cultural heritage restoration. In the automotive industry, they can be used to clean engine parts, body panels, and wheels. In aerospace, they are used to remove coatings from aircraft components. In cultural heritage restoration, they can clean ancient artifacts and monuments without causing damage.

Laser cleaning machines have several remarkable features:

One of their key advantages is the ability to clean complex shapes and hard-to-reach areas. The focused laser beam can be precisely directed to clean areas that would be difficult or impossible to access with traditional cleaning methods. This makes them ideal for cleaning intricate parts and components.

They also offer a high degree of controllability. Operators can adjust the laser parameters such as power, pulse duration, and frequency to achieve the desired cleaning effect. This allows for customized cleaning for different materials and contamination levels.

Moreover, laser cleaning is a non-contact process. There is no physical abrasion or mechanical stress on the surface being cleaned, reducing the risk of damage to the substrate. This is particularly important for delicate materials or parts that require gentle cleaning.

In terms of safety, laser cleaning machines are equipped with safety features such as protective enclosures and interlocks to prevent accidental exposure to the laser beam. Operators are also required to wear appropriate safety gear such as laser safety glasses.

The technology behind laser cleaning machines continues to evolve. New advancements are being made in laser sources, optics, and control systems to improve performance and expand applications. For example, the development of fiber lasers has increased the power and efficiency of laser cleaning machines, making them even more effective for industrial applications.

What Is the Principle of a Laser Cleaning Machine?

The principle of a laser cleaning machine is based on the interaction between laser beams and the materials to be cleaned. Here are the main aspects:

1. Photothermal Effect

- When the laser beam irradiates the surface with contaminants, the high-energy laser is absorbed by the contaminants. This absorption causes a rapid increase in temperature.

- As the temperature rises, the contaminants such as rust, paint, or oxide layers reach their boiling point or sublimation temperature.

- At this point, the contaminants either vaporize directly into gas or undergo sublimation, transforming from a solid state to a gaseous state without passing through a liquid phase. This process effectively removes the contaminants from the surface.

2. Photoablation Effect

- In some cases, for certain types of contaminants or materials, the laser energy can cause a process called photoablation.

- Photoablation occurs when the laser beam has enough energy to break the chemical bonds of the contaminants, causing them to disintegrate and be removed from the surface.

3. Selective Cleaning

- Laser cleaning is highly selective. The laser can be precisely adjusted to target only the contaminants while minimizing damage to the underlying substrate.

- This is because different materials have different absorption characteristics for laser light. By choosing the appropriate laser parameters, it is possible to ensure that the laser energy is mainly absorbed by the contaminants rather than the substrate.

What Are the Benefits of Using a Laser Cleaning Machine?

1. High cleaning efficiency

- Laser cleaning is a highly efficient process. The laser beam can quickly remove contaminants from large areas or complex geometries in a short time. This saves a considerable amount of time compared to traditional cleaning methods.

- It can clean multiple surfaces simultaneously, further enhancing productivity.

2. Precision cleaning

- The laser beam can be precisely focused and controlled, allowing for targeted cleaning of specific areas. This is extremely useful for delicate or intricate parts where traditional cleaning methods may cause damage.

- It can clean areas that are difficult to access with other methods, ensuring thorough cleaning.

3. Non-contact cleaning

- This reduces the risk of damage to the substrate and preserves the integrity of the material.

- It is ideal for cleaning sensitive materials such as electronics, optics, and historical artifacts.

4. Environmentally friendly

- Laser cleaning does not require the use of chemicals or solvents, which reduces the environmental impact and eliminates the need for disposal of hazardous waste.

- It is a clean and green technology that meets the increasing demand for sustainable cleaning solutions.

5. Versatility

- They can remove different types of contaminants such as rust, paint, oil, dirt, and oxides.

6. Cost-effective in the long run

- The reduced labor costs, increased productivity, and minimal maintenance requirements can lead to significant savings over time.

7. Improved quality

- Laser cleaning provides a superior cleaning result, leaving the surface clean and free of contaminants. This can improve the quality of the finished product and enhance its performance and durability.

In summary,

laser cleaning machines are a revolutionary cleaning solution that offers precision, controllability, safety, and environmental friendliness. As technology continues to advance, their applications are likely to expand further in various industries.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.