Laser Knowledge

What is the difference between the co2 and fiber laser cutter?

Since there are many diverse physical properties of lasers, the processing of CO2 CNC laser cutting machine and fiber laser cutting machine is also different. That is, they all have their own advantages and disadvantages, as well as their own advantages and disadvantages, depending on the machining object.

The CO2 CNC laser cutting machine design is typically driven by laser power to illuminate. Light is transmitted to the laser head through a reflection of a plurality of mirrors, and is concentrated in focus mounted on the laser head. Therefore, the processing material is raised to the gas, which has a very high temperature, which is suddenly absorbed, thereby achieving the purpose of cutting.

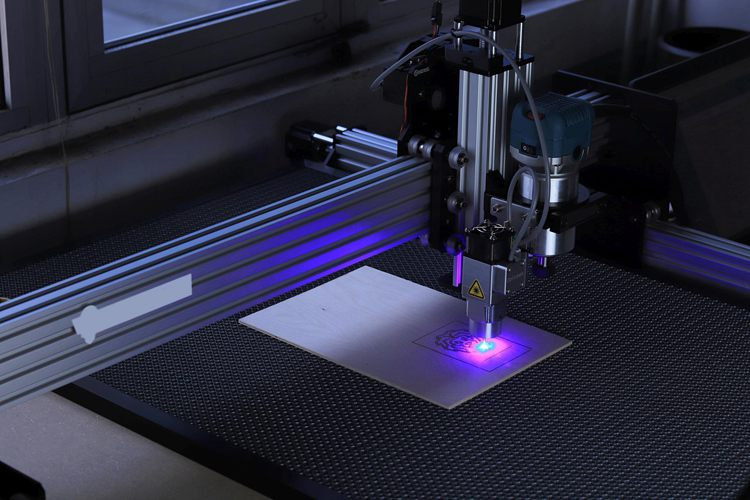

The fiber laser cutting machine is a laser cutter that uses the fiber laser generator as a light source. Fiber laser metal cutting machine are a new type of fiber laser that is newly developed in the world. It outputs high-energy-density laser beams and accumulates on the surface of the workpiece, allowing the area of the workpiece to be illuminated and instantaneously melted and evaporated by ultrafine focus. Automatic cutting is achieved by using a numerical control mechanical system to move the point illumination position, which is a high speed and high precision.

Applicable industry

There are two main conditions suitable for CO2 laser cutting machine products. On the one hand, this is a unique component that requires even cut, including non-metallic materials in 3mm, 3mm and 20 mm, for service industries, such as advertising and decoration, etc., as well as complex cutting profiles. A small amount of workpiece. And used to save costs and circulation of manufacturing molds.

The fiber laser tube cutting machine has higher processing accuracy, widely used in aerospace, electronic, electrical, precision parts, automotive, machinery production industry, craft gift, tool processing, decoration, advertising, metal processing, kitchen processing and other manufacturing and processing industries.

Comparison of Advantages of fiber laser sheet cutting machine and CO2 laser metal cutting equipment.

1. Control from the structure of the laser device

In CO2 laser cutting techniques, the carbon dioxide gas is a medium that produces a laser beam. However, the fiber laser pipe cutting machine is transmitted through a diode and fiber optic cable. The fiber laser system generates a laser beam by pumping multiple diodes. It then passes through a flexible fiber optic cable to the laser cutting head by a mirror, which has many advantages. First, it is the size of the cutting table. In gas laser technology, the mirror must be disposed within a certain distance. The range of fiber optic laser cutter is not limited. Even fiber lasers can also be mounted next to the plasma cutting head of the plasma cutting bed. Moreover, the system is more compact due to the optical fiber with the same power gas cutting system.

2. Control of conversion efficiency from the light light

The most important and significant advantages of fiber cutting techniques should be its energy efficiency. The fiber laser cutting system has a solid digital module and a single design of the fiber laser cutting system with a single design using the fiber laser complete solid-state digital module and the fiber laser cutting system. For each power unit of the carbon dioxide cutting system, the actual general utilization is about 8% to 10%. For fiber laser cutting systems, users can expect higher power efficiency, 25% to 30%. In other words, the fiber cutting system consumes approximately three to five times the energy than the carbon dioxide cutting system, resulting in an increase in energy efficiency more excellent than 86%.

3. Cut the effect

The best fiber laser cutter has a short wavelength characteristic that can increase the absorption of beams by cutting materials, and materials such as brass and copper, and non-conductive materials. A more concentrated beam produces a smaller focus and deeper focus, so the best fiber laser cutting machine can more efficiently cut thinner materials and medium thickness materials. When the thickness of the cutting material is as high as 6 mm, the cutting speed of the 1500w fiber laser cutting machine corresponds to the cutting speed of the 3 kW CO2 metal laser cutting machine. Since the operating cost of fiber cutting is lower than the cost of conventional carbon dioxide cutting systems, it is understood that the increase in the output and reduced commercial costs are reduced.

4. Control from maintenance costs

Metal fiber laser cutting machine is more environmentally friendly, and machine maintenance is convenient. For example, the CO2 laser system requires regular maintenance; the mirror needs to maintain and calibrate, and the resonator needs regular maintenance. However, fiber laser cutting solutions have hardly need to maintain. CO2 laser cutting system requires carbon dioxide as laser gas. Therefore, due to the purity of carbon dioxide gas, it should be regularly cleaned, and the cavity is contaminated. For a 1000W CO2 system, the project takes at least $ 20,000 a year. In addition, many carbon dioxide incisions require high-speed axial turbines to provide laser gases, while turbines require maintenance and refurbishment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.