Laser Knowledge

What You Need to Know About Sheet Metal Laser Cutting

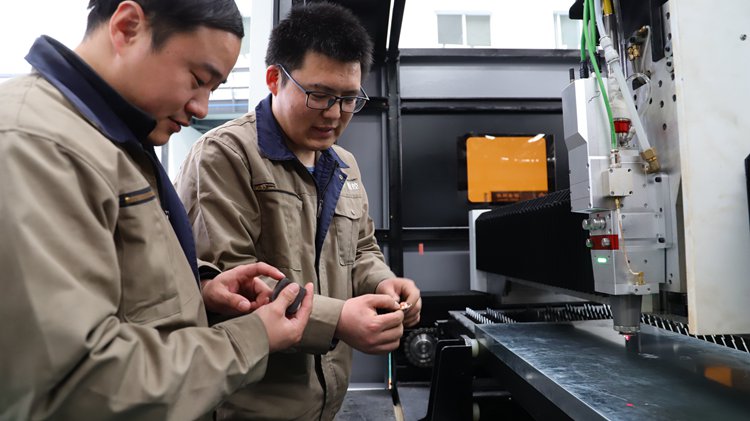

Sheet metal laser cutting offers numerous advantages, including high precision, speed, versatility, and the ability to cut intricate shapes and patterns. It is commonly used in industries such as automotive, aerospace, electronics, and architectural fabrication, where precise and efficient cutting of sheet metal is required.

Sheet Metal Laser Cutting Machines Process

- Material Loading: Sheet metal, typically in the form of flat sheets, is loaded onto the machine’s work surface.

- Programming: A computer-aided design (CAD) program is used to create a digital model of the desired cut. The operator specifies cutting parameters such as the path, depth, and speed.

- Laser Cutting: The machine uses a high-powered laser beam, often generated by a carbon dioxide (CO2) laser or fiber laser, to cut through the sheet metal. The laser beam melts or vaporizes the material along the programmed path.

- Precision and Accuracy: Sheet metal laser cutting machines offer high precision and accuracy, allowing for intricate and detailed cuts. This is crucial for applications where tight tolerances are required.

- Assist Gas: Assist gas, such as nitrogen or oxygen, is often used during the cutting process to blow away molten metal and debris, resulting in a cleaner cut.

- Automatic Focus: Some advanced machines have automatic focusing systems that adjust the focal length of the laser beam based on the thickness of the sheet metal. This ensures optimal cutting performance for different materials.

- Nesting Software: Nesting software is often employed to optimize the arrangement of cuts on the sheet, minimizing material waste and maximizing efficiency.

How Does A Metal Laser Cutting Machine Work?

The energy of the laser is concentrated into a high-density beam in the form of light. The laser beam is transmitted to the work surface, generating enough heat to melt the material, and the high-pressure gas coaxial with the beam directly removes the fused metal to achieve the purpose of metal cutting. This shows that laser metal cutting is essentially different from CNC machining.

A laser metal cutting machine uses the laser beam emitted from the laser generator to focus on the laser beam irradiation condition of high power density through the external circuit system. The laser heat is absorbed by the workpiece material and the workpiece temperature rises sharply. After reaching the boiling point, the material begins to vaporize and form holes, as the relative position of the beam and the workpiece moves, will eventually form a slit in the material.

The technological parameters (cutting speed, laser power, gas pressure, etc.) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure. During laser-cut metal, auxiliary gas suitable for the material to be cut is also added. When cutting steel, oxygen must be used as an auxiliary gas to produce an exothermic chemical reaction with the molten metal to oxidize the material, while helping to blow away the slag in the slit. For metal parts with high processing accuracy, nitrogen can be used as an auxiliary gas in the industry.

What Are Metal Laser Cutters Used For?

Laser metal cutting machines are widely used in industrial manufacturing of metal fabrication, school education, small businesses, home business, small shop and home shop for sheet metal fabrication, aviation, spaceflight, electronics, electrical appliances, kitchenware, auto parts, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, metal signs, metal logos, metal tags, metal profiles, metal letters, metal words, metal arts, metal crafts, metal gifts, metal tool fabrication, metal foils, adornment, advertising and other metalworking industries.

Most organic and inorganic materials can be cut by laser. In the metal fabrication industry, which occupies a heavy weight in industrial manufacturing, many metal materials, regardless of their hardness, can be cut without deformation (using the most advanced laser metal cutter to cut the thickness of industrial steel is close to 20mm). Of course, for high-reflectivity materials such as gold, silver, copper and aluminum alloys, they are also good heat transfer conductors, so laser cutting is difficult or even impossible to cut (some difficult materials can be cut using pulsed laser beams, due to the extremely high peak power of the pulse wave, the absorption coefficient of the material to the beam will increase sharply instantly).

Metal laser cutters are available for stainless steel, carbon steel, tool steel, galvanized steel, spring steel, alloy, iron, aluminum, copper, brass, silver, gold, titanium, nickel, manganese, cobalt, chromium, lead and other metals.

Hot sale fiber laser cutting machine

Metal Tube Fiber Laser Cutting Machine iGR-T

The tube laser cutting machine is a laser cutting machine specially designed for tube cutting. It can cut round tubes, square tubes, oval tubes, rectangular tubes and irregular tubes. It is equipped with a special cutting operating system, which is simple to operate, high precision and professional. Strong, suitable for professional profile cutting, widely used in sports equipment, petroleum pipelines, chemical equipment and other industries. It can cut carbon steel and stainless steel.

Flatbed Fiber Laser Cutting Machine iGR-F

Dual-use Fiber Laser Cutting Machine iGR-FT

Dual-worktable Fiber Laser Cutting Machine iGR-E

Protective Fiber Laser Cutting Machine iGR-P

Full-protection fiber laser cutting machine adopts a fully enclosed laser protective cover, is equipped with a special laser protective glass observation window, which is overall beautiful, safe and environmentally friendly; at the same time, it is equipped with a special exchange platform for fast exchange speed.

It is a high-end special equipment for laser cutting of sheet metal, and it is the first choice for modern manufacturing enterprises.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.