Laser Knowledge

What’s the difference of fiber laser and CO2 laser?

Acting because the mainstream cutting solutions, fiber laser and CO2 laser both take up an excellent place within the modern laser industry. But if you dive into laser machines, you’ll find differences between these two technologies.

Which laser type that application?

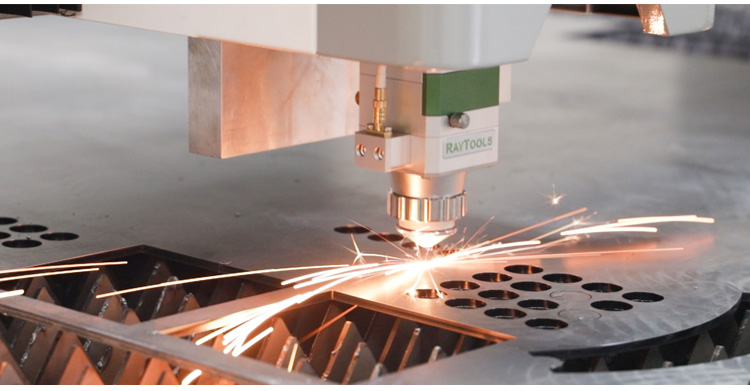

Fiber Laser

The focused high energy density laser beam is irradiated on the surface of the material, that the material to be melted or vaporized instantaneously, and then using corresponding gas to blow away the melted or vaporized material. Finally, the cutting is formed with the movement of the laser beam.

Compared to gas lasers or solid state lasers, essential advantages of fiber lasers include:

Excellent beam quality (light-concentrating beam from optical fiber)

Simple , compact, electrically and optically efficient (small footprint and low power consumption by fiber amplification)

Compatibly powerful and reliable (realized by high brightness, high power semiconductor lasers as pumping light)

Maintenance free (the entire optical fiber setups without lenses, mirrors)

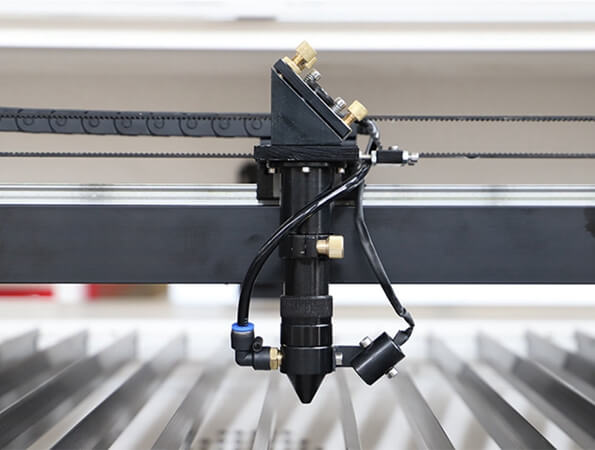

CO2 Laser

Quality – Quality is consistent throughout all thicknesses of fabric .

Flexibility – high, suitable for all material thicknesses.

Safety – CO2 laser light (10µm) is best absorbed by the machine frame, which lowers the danger of irreparable damage to the retina. Personnel shouldn’t look directly at the cutting process through the acrylic panel within the door because the bright plasma also presents a risk to sight over a period of your time . (Similar to watching the sun.)

Beam guidance – mirror optics.

Cutting with Oxygen (flame cutting) – there’s no difference in quality or speed shown between the 2 sorts of lasers.

Also, let’s show some features that make fiber laser machines outstanding.

1. Fiber laser is delivered through a laser optic cable rather than mirrors and channel employed by CO2 laser cutting machine, reducing power loss and increasing energy efficiency. So cost are often lowered directly.

2. The fiber laser wavelength is 1064nm, which is ten times shorter than that of the CO2 laser. The more focused beam are going to be produced to interact with different metals.

3. Fiber laser cutters can have exchange platforms that materials and finished cutting sheets can load or unload automatically to save time and labour.

4. As sheet metals are more popular in manufacturing industries, sheet metals processing has played an increasingly important part within the various metal business. Fiber laser machines can perfectly cater to the present need, while CO2 laser machines are more suitable for thick plates cutting.

5. Maintenance is additionally an important part for machines. and tiny maintenance and devices replacement are required for a fiber laser machine, saving worry and money. Contrarily, a CO2 laser machine needs regular and annual maintenance with components replacement, which may cost you quite ten thousand a year.

6. Fiber laser metal cutting machine performs with higher cutting precision and excellent leading edge , for the plenty of cutting table ensures the steadiness within the whole cutting process and therefore the gas will blow away the residue produced from cutting materials.

These introductions can’t decide your laser business, but if you would like to refresh your laser cutting business or upgrade your laser machines, we are willing to supply you with customized solutions. And for more details, you’ll also search for more posts under this blog.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.