Laser Knowledge

Where to Buy Laser Cutting Machine?

China has emerged as a global leader in the manufacturing and supply of laser cutting machines. These machines play a crucial role in various industries such as automotive, aerospace, electronics, and metal fabrication. The Chinese laser cutting machine industry is known for its advanced technology, diverse product range, and competitive pricing, making it a preferred choice for both domestic and international customers.

Laser Cutting Machine Manufacturer

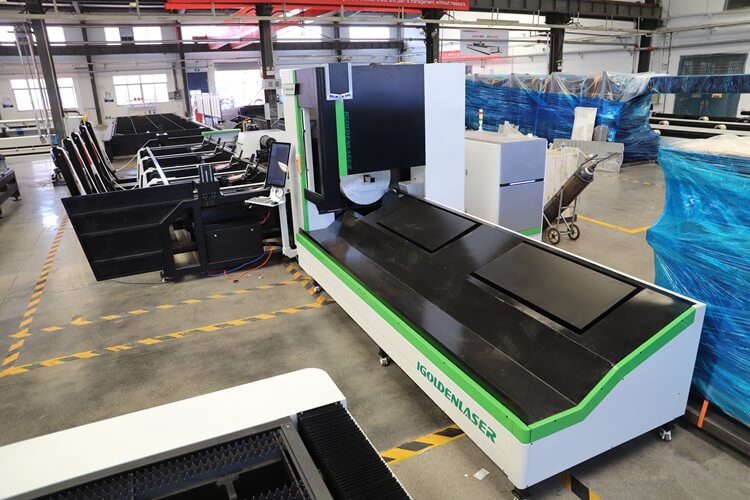

IGOLDENLASER is another leading Chinese manufacturer that specializes in high – tech laser equipment. It has a strong focus on innovation and quality, and its products are widely used in industries that demand high – precision cutting, such as electronics and precision machinery.

IGOLDENLASER offers a comprehensive range of laser cutting machines, including those designed for cutting flat sheets and three – dimensional (3D) laser cutting machines. Their flat – sheet laser cutters are known for their high cutting speed and accuracy. The 3D laser cutting machines are used in applications where complex geometries need to be cut, such as in the automotive and aerospace industries. The machines are capable of handling a variety of materials, including metals like steel, aluminum, and titanium, as well as non – metals such as plastics and composites.

IGOLDEN’s Laser invests heavily in research and development. They have developed advanced laser beam control systems, which ensure precise cutting paths and high – quality cut edges. Their machines also feature intelligent software that can optimize cutting parameters based on the material and design requirements. Additionally, they have been at the forefront of improving energy – efficiency in laser cutting machines, reducing operating costs for users.

Types of CNC Fiber Laser Cutting Machine

Fiber laser cutting machine, also known as metal laser cutter, fiber laser cutter, is a kind of CNC metal laser cutting machine, it is characterized of high running precision & cutting speed, advanced function, thus is ideal machine for different kinds of metal fabrications. The cnc fiber laser cutting machine is equipped with IPG fiber laser of different powers from 1000W to 60000W or even more, it can be used for different profiles, including sheet metal, round pipe, square/rectangular tube, beam profile of stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with different thicknesses.

CNC fiber laser cutting machines can be divided into different types in terms of the machine structure & funcitons, including:

1).Sheet Metal Laser Cutting Machine

This machine is mainly used for sheet metal or steel plate, it has a machine table which can be welded by steel plates or even casted, when working, the steel plate is placed onto the tabletop and then laser cutting will be carried out automatically under the control of controller system. 2 kinds of machine tables are available for the sheet metal laser cutting machine: single table type and exchange table type, they mainly differ in the quantity of tables and working efficiency. Actually, running will have to be suspended after cutting of one plate is finished as the plate will have to be changed manually.

Exchange table type machine, however, has quite another story: cutting can be continous with no stop as shift will be carried out automatically as when one plate is under cutting, another new plate will be ready on the other machine table, which, undoubtedly, will increase the working efficiency greatly and save much labor cost & times.

2).Tube Laser Cutting Machine

Tube laser cutting machine is dedicated for pipe profiles, including round pipe, square tube, rectangular tube, oval tube, angle steel, beam profile, etc. This machine has quite different machine strcuture which is mainly composed of mchine body, front & rear chuck, wheel support, waste collecting, loading system, unloading system, etc. When working, the pipe is lifted manually or automatically by loading system, then front & rear chucks will fix the pipe and machine will carry out cutting as the program set in the control system. Tube laser cutting machine is an advanced cnc cutting machine for its advantages of high automation, easy operation and high working efficiency.

3).Tube and Plate Laser Cutting Machine

Tube laser cutting machine is dedicated for pipe profiles, including round pipe, square tube, rectangular tube, oval tube, angle steel, beam profile, etc. This machine has quite different machine strcuture which is mainly composed of mchine body, front & rear chuck, wheel support, waste collecting, loading system, unloading system, etc. When working, the pipe is lifted manually or automatically by loading system, then front & rear chucks will fix the pipe and machine will carry out cutting as the program set in the control system. Tube laser cutting machine is an advanced cnc cutting machine for its advantages of high automation, easy operation and high working efficiency.

What Is A Fiber Laser Cutter Used For?

Applicable Industries:

The fiber laser cutter can be used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, Metal external processing, kitchenware processing and other manufacturing and processing industries.

Applicable Materials:

The fiber laser cutter can be used for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminized zinc plate, pickling sheet, copper, silver, gold, titanium and other metal plates and pipes.

What Is Fiber Laser Cutting Machine Price

CNC fiber laser cutter machines of different types & models are available, so it is hard to give the exact price, generally the price ranges from $12,000 to $120,000, depending on actual model & parts. There are some factors which affect the price of fiber laser cutter machine, such as driving system, control system, brand & power of laser power, spare parts, etc, Also, some other charge & fees will have to be taken into consideration, including shipping costs, tax and customs clearance, etc.

Cost – Effectiveness Economies of Scale

China’s large – scale manufacturing capabilities enable it to produce laser cutting machines at a lower cost. The country has a well – developed supply chain for laser – related components, which helps in reducing the production cost. Manufacturers can source parts such as laser generators, motors, and optical components at a more competitive price due to the large volume of production and local availability of suppliers.

Affordable Pricing

As a result of the cost – advantages in production, Chinese – manufactured laser cutting machines are generally more affordable than their counterparts from other countries. This makes them accessible to a wider range of customers, including small – and medium – sized enterprises (SMEs) and hobbyists. For example, a mid – range Chinese fiber laser cutting machine may cost around 30% – 50% less than a similar – quality machine from a Western brand.

Advantages Of Fiber Laser Cutting Machine

(1).High Cutting Accuracy:

Laser cutting machine positioning accuracy is 0.05mm, and repeated positioning accuracy is 0.03mm.

2).Narrow Cutting Slit:

The laser beam is focused into a very small light spot, so that the focal point reaches a high power density, the material is quickly heated to the degree of vaporization, and the hole is evaporated. With the relatively linear movement of the beam and the material, the hole is continuously formed with a narrow slit, and the width of the slit is generally 0.10-0.20mm.

(3).Smooth Cutting Surface:

The cutting surface has no burrs, and the roughness of the cutting surface is generally controlled within Ra6.5.

(4).Fast Cutting Speed:

The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than the linear cutting speed.

(5).Good Cutting Quality:

Non-contact cutting, the cutting edge is little affected by heat, basically no thermal deformation of the workpiece, completely avoid the collapse of the material formed during punching, the cutting seam generally does not require secondary processing.

(6).No Damage to Workpiece:

The laser cutting head will not contact the surface of the material, ensuring that the workpiece is not scratched.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.