Buyer Guide

Which Laser Type Is the Best for Personalize Leather Wallet?

Laser Engraving & Cutting Leather

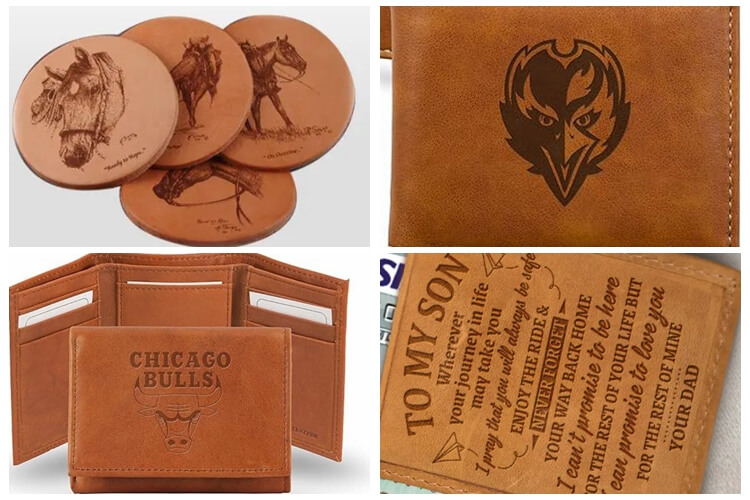

Creating personalized leather wallets using laser technology has become increasingly popular due to the precision and versatility of laser engraving and cutting machines. Selecting the right type of laser is critical to achieving the best results on leather products. In this article, we will explore the types of lasers available, their suitability for leather, and a detailed guide to laser engraving and cutting for personalizing leather wallets. We will also discuss tips for achieving the best results, considerations for safety, and the overall benefits of using laser technology in leather crafting.

1. Introduction to Laser Technology for Leather Engraving and Cutting

Laser technology has revolutionized many industries, including fashion, design, and manufacturing. For leatherworking, laser engraving and cutting allow artisans and manufacturers to create intricate designs with a level of precision that is difficult to achieve by hand. Personalizing leather wallets using lasers enables the addition of monograms, logos, intricate patterns, or any other custom designs, making each piece unique.

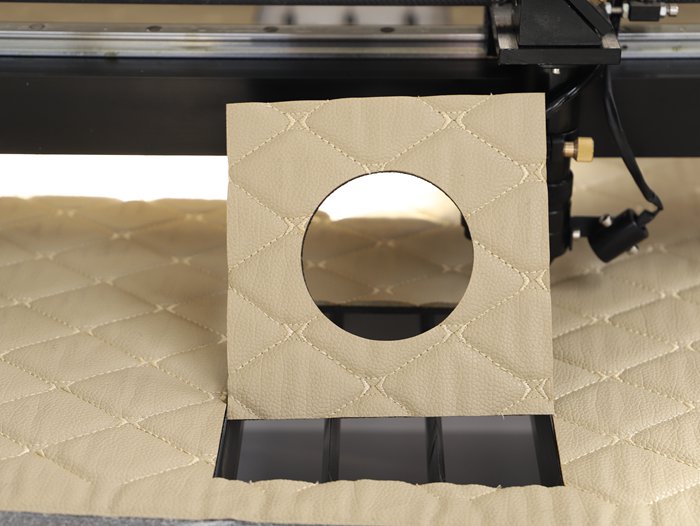

Laser engraving burns or vaporizes the surface of the leather to create a design, while laser cutting uses focused light to slice through the material entirely. The process is fast, highly accurate, and repeatable, which is ideal for both small-scale artisans and large-scale manufacturers.

2. Types of Lasers for Leather Engraving and Cutting

There are several types of lasers used for engraving and cutting leather, but the most common options are:

2.1 CO₂ Lasers

CO₂ lasers are the most commonly used lasers for engraving and cutting leather. They use a gas mixture (primarily carbon dioxide) as the lasing medium, and they operate in the infrared spectrum. These lasers are popular because they work exceptionally well with organic materials like leather, wood, and fabric.

- Suitability for Leather: CO₂ lasers can engrave and cut leather with high precision, creating smooth, clean edges. They are versatile enough to handle both thin and thick leather, making them ideal for personalizing wallets, belts, and other leather products.

- Engraving Depth: CO₂ lasers offer excellent control over engraving depth, allowing artisans to create shallow, intricate designs or deep engravings for a more pronounced effect.

- Power Range: CO₂ lasers come in various power levels, typically ranging from 30W to 150W. For engraving leather, a lower power setting (e.g., 40W-60W) is generally sufficient, while cutting thicker leather may require higher power.

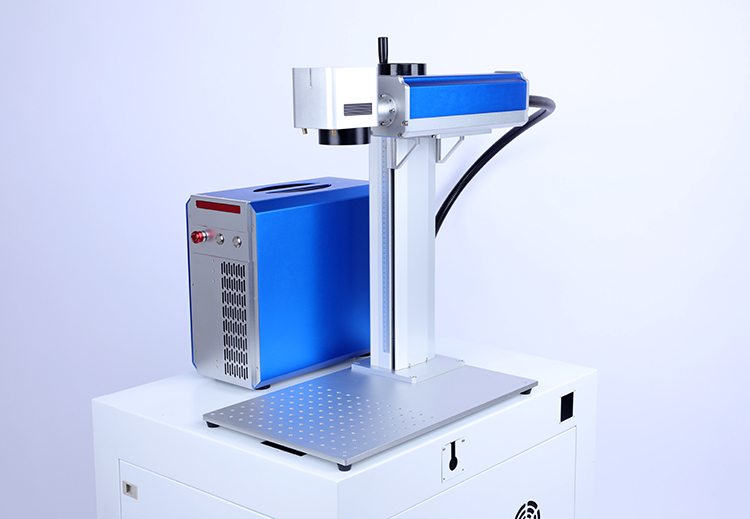

2.2 Fiber Lasers

Fiber lasers operate using a different mechanism than CO₂ lasers. They use an optical fiber doped with rare earth elements as the medium, and they emit light at a much shorter wavelength. Fiber lasers are commonly used for metal engraving but are less suitable for organic materials like leather.

- Suitability for Leather: While fiber lasers can engrave leather, they tend to scorch or burn the material more easily due to their shorter wavelength. This makes them less ideal for leather personalization unless the desired effect is a high-contrast, burnt appearance.

- Engraving Depth: Fiber lasers are not typically used for deep engraving on leather. Their primary use in leatherwork might be for surface marking or creating highly contrasting designs.

2.3 Diode Lasers

Diode lasers are a less common choice for leather engraving and cutting, as they generally have lower power levels compared to CO₂ and fiber lasers. These lasers are used in consumer-grade laser engravers and may be suitable for hobbyists or small-scale projects.

- Suitability for Leather: Diode lasers can work on thin leather but are less effective for thicker materials or projects requiring deep cuts or engravings. Their lower power means they may struggle with certain types of leather or produce inconsistent results.

- Engraving Depth: Due to their lower power, diode lasers are typically limited to light surface engravings on leather.

3. Why CO₂ Lasers Are the Best Choice for Personalizing Leather Wallets

Given the characteristics of the different laser types, CO₂ lasers are the best choice for personalizing leather wallets. They offer the perfect balance of power, precision, and versatility for working with leather.

- Precision: CO₂ lasers provide excellent control, allowing for highly detailed engravings on small surfaces like wallet panels.

- Versatility: They can engrave and cut a wide range of leather types, including vegetable-tanned and chrome-tanned leather.

- Customizable Settings: The ability to adjust power, speed, and resolution means CO₂ lasers can be fine-tuned to achieve different effects on leather, from light etching to deep engravings or even cutting intricate shapes.

4. Preparing Leather for Laser Engraving and Cutting

To achieve the best results when personalizing a leather wallet with a CO₂ laser, it is essential to prepare the material properly. The quality and type of leather, the condition of the surface, and even how the leather is positioned in the laser bed can all affect the outcome.

4.1 Choosing the Right Leather

Not all types of leather are suitable for laser engraving and cutting. The two most commonly used types for laser work are:

- Vegetable-Tanned Leather: This leather is tanned using natural plant extracts and is highly recommended for laser engraving and cutting. It responds well to the laser, creating a clean, dark engraving with minimal scorching or burning. It is often used in high-end products like wallets.

- Chrome-Tanned Leather: This type of leather is treated with chemicals during the tanning process, making it more resistant to heat. While it can be laser engraved, it may produce more fumes, and the result may not be as sharp as with vegetable-tanned leather.

4.2 Cleaning and Masking the Leather

Before engraving or cutting, it is essential to clean the leather surface to remove any dust or oils that could interfere with the laser. Some artisans use masking tape to cover the leather, which helps prevent burn marks or residue from forming on the surface.

4.3 Positioning and Securing the Leather

Ensuring the leather lies flat and is properly secured in the laser bed is crucial for accurate results. Any wrinkles or uneven surfaces can distort the engraving or cutting, leading to inconsistent designs.

5. Setting Up the Laser for Engraving and Cutting

Each CO₂ laser machine comes with software that allows you to adjust the settings for engraving and cutting. These settings are critical for achieving the desired effect on leather wallets.

5.1 Laser Power and Speed

- Engraving: For engraving leather, a lower power setting with a slower speed is typically used. This allows the laser to lightly burn the surface without cutting too deeply. The exact power and speed settings will depend on the type of leather and the depth of engraving desired.

- Cutting: For cutting leather, higher power settings and slower speeds are necessary, especially for thicker materials. A few passes with the laser may be needed for thicker cuts, but too many passes can cause the edges to burn or char excessively.

5.2 DPI (Dots Per Inch)

The DPI setting controls the resolution of the engraving. Higher DPI settings result in finer details, but they also take longer to engrave. For intricate designs on a small surface like a wallet, a DPI of 300-600 is typically recommended.

5.3 Focus and Beam Alignment

Properly focusing the laser beam is essential for sharp engravings and clean cuts. Most CO₂ laser machines come with a manual or automatic focusing system. Ensuring the beam is properly aligned with the leather surface will produce the best results.

6. Post-Engraving and Cutting Treatment

After engraving or cutting, some additional steps may be necessary to finish the leather wallet.

6.1 Cleaning Burn Residue

Laser engraving and cutting can leave behind a residue, especially if the leather is masked. Removing this residue with a damp cloth or leather cleaner is essential to achieve a professional finish.

6.2 Conditioning the Leather

Laser engraving and cutting can cause leather to dry out, so applying a leather conditioner or oil will help restore its natural softness and luster. This step is particularly important for vegetable-tanned leather, which can stiffen after exposure to the laser.

6.3 Edge Finishing

If the wallet has been laser cut, the edges may require some finishing to smooth out any roughness. This can be done by sanding the edges lightly or using a burnishing tool to create a polished edge.

7. Safety Considerations When Laser Engraving Leather

Laser engraving and cutting can produce fumes and smoke, especially when working with certain types of leather. It is essential to follow safety protocols to protect both the user and the environment.

7.1 Ventilation

Always use a laser machine in a well-ventilated area or with an integrated fume extraction system. Leather, especially chrome-tanned leather, can release harmful fumes when engraved or cut.

7.2 Protective Gear

Wearing safety goggles is recommended when operating a laser, especially if the machine does not have an enclosed chamber. Additionally, using a respirator or mask may be necessary if the fume extraction system is insufficient.

7.3 Fire Risk

Laser engraving and cutting involve heat, which can pose a fire risk. Always monitor the machine during operation and keep a fire extinguisher nearby.

8. Benefits of Using Laser Technology for Leather Wallet Personalization

There are several reasons why laser engraving and cutting have become the preferred method for personalizing leather wallets:

- Precision: Lasers can create incredibly detailed designs that are difficult or impossible to achieve by hand.

- Efficiency: The process is fast, allowing for quick turnaround times on custom orders.

- Consistency: Lasers can replicate the same design over and over, ensuring consistency in large production runs.

- Customization: With a laser, it is easy to add personal touches like.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.