Buyer Guide

Wood Floor Laser Cleaning Machine

Laser cleaning is a process that uses focused laser beams to remove contaminants, old finishes, and surface imperfections from wood floors. This non-contact method is both precise and efficient, making it an ideal choice for renovation projects.

Wood Floor Laser Cleaning Machine

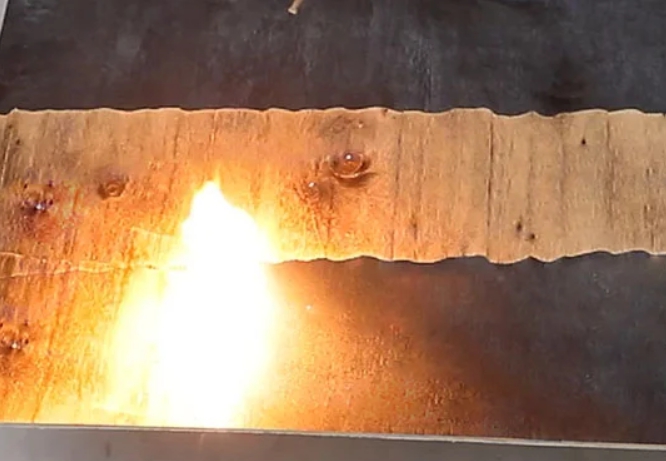

The laser cleaning process involves directing a laser beam onto the wood surface. The energy from the laser is absorbed by the contaminants, causing them to vaporize or detach from the surface. This leaves the underlying wood clean and ready for refinishing.

Pulse laser cleaning machines represent a significant advancement in surface cleaning and preparation technologies. Their precision, versatility, and environmental benefits make them a preferred choice in many industries.Pulse laser cleaning machines are advanced tools used for precision cleaning and surface preparation. They employ short bursts of high-intensity laser light to remove contaminants, oxides, paint, rust, and other unwanted materials from various surfaces without causing damage to the substrate.

A wood floor cleaning machine uses laser technology to remove dirt, grime, and stains from the surface of wood floors. Unlike traditional cleaning methods, which rely on chemicals and physical scrubbing, laser cleaning is a non-contact process that vaporizes contaminants without damaging the underlying material.The pulse laser system focuses a high-energy laser beam onto the surface to be cleaned. The laser pulses are typically in the nanosecond to microsecond range.

Key Features of wood foloor Laser Cleaning Machines

- Precision Cleaning: Targets specific areas with pinpoint accuracy, ensuring thorough cleaning without affecting adjacent surfaces.

- Non-Abrasive: Eliminates the risk of scratches and wear associated with mechanical cleaning methods.

- Chemical-Free: Uses no harsh chemicals, making it an environmentally friendly option.

- Efficiency: Delivers fast and effective cleaning, reducing downtime and labor costs.

Benefits of Using a Laser Cleaning Machine for Wood Floors

The adoption of laser cleaning technology for wood floors offers numerous advantages, making it an attractive option for homeowners and businesses alike.

Enhanced Cleaning Performance

Laser cleaning machines provide superior cleaning performance by effectively removing stubborn stains, dirt, and even mold from wood floors. The precision of the laser ensures that only the contaminants are targeted, leaving the wood surface intact and undamaged.

Preservation of Wood Integrity

Traditional cleaning methods can sometimes compromise the integrity of wood floors, leading to scratches and wear over time. Laser cleaning, being a non-contact process, preserves the natural beauty and strength of the wood, extending its lifespan.

Eco-Friendly Solution

With growing concerns about environmental impact, the use of chemical-free cleaning methods is becoming increasingly important. Laser cleaning machines offer an eco-friendly alternative, reducing the need for harsh chemicals and minimizing waste.

Cost-Effective Maintenance

While the initial investment in a laser cleaning machine may be higher than traditional equipment, the long-term savings in labor, cleaning supplies, and floor maintenance make it a cost-effective choice.

In conclusion, laser cleaning offers a transformative approach to wood floor renovation, combining precision, efficiency, and sustainability. By understanding its benefits and implementation, you can revitalize your wood floors and enhance the beauty of your space.

- Preserves Wood Quality: Gentle on wood, preventing damage.

- Efficient: Quickly removes stubborn stains and coatings.

- Versatile: Can be used on various wood finishes and types.

- Reduced Labor: Minimizes manual scrubbing and sanding.

Applications

- Restoration: Ideal for antique and high-value wood floors.

- Maintenance: Regular cleaning to maintain appearance and longevity.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.