The MDF laser cutting machine is a device that uses a laser beam to cut medium-density fiberboard (MDF) materials. MDF is a versatile engineered wood product made from wood fiber, wax, and resin and is a popular material in woodworking and crafts. Laser cutting offers precision and versatility when working with MDF, making it the preferred method for many applications. Laser cutting offers exceptional precision and accuracy, allowing for complex and detailed cuts and engravings on MDF.

This is because the MDF laser cutting machine uses high-precision control software. The laser head follows the designated cutting path under the guidance of the control software, thereby completing high-precision cutting. Unlike traditional cutting tools, laser cutting does not involve direct physical contact with the material, reducing the risk of damage, cracking, or chipping of the material. Additionally, laser cutting minimizes material waste as it optimizes the placement of cuts on MDF, thus reducing scrap.

A Wood MDF Laser Cutting Machine is a high-tech device that uses a focused laser beam to cut through wood and MDF with exceptional accuracy. The laser beam is generated by a powerful laser source and is directed onto the material through a series of mirrors and lenses. As the laser beam interacts with the material, it heats and melts it, creating a clean and precise cut.

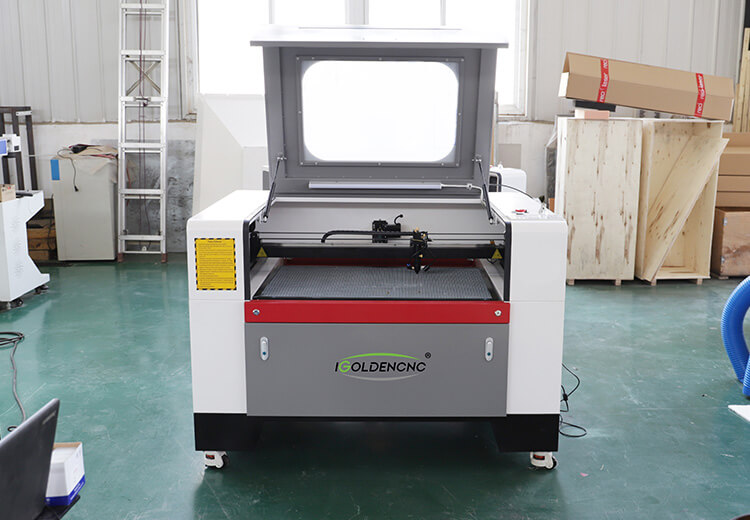

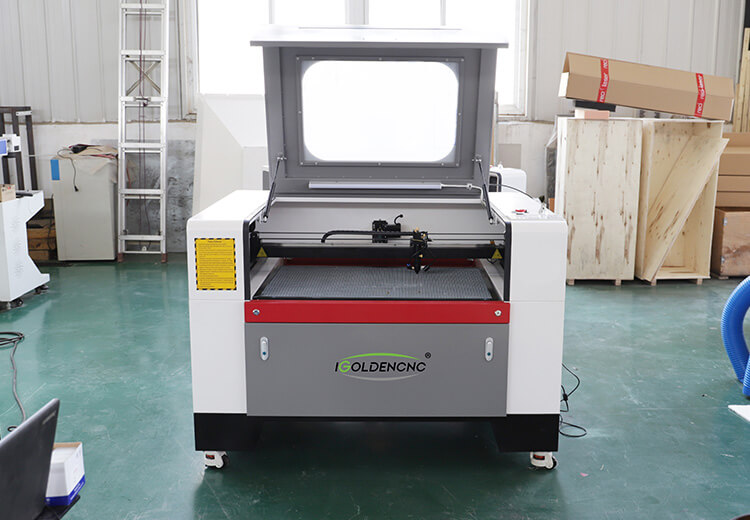

These machines come in a variety of sizes and configurations, making them suitable for different applications and workspaces. From small desktop models for hobbyists and small businesses to large industrial-grade machines for high-volume production, there is a Wood MDF Laser Cutting Machine to meet every need.

When the large format sheets of plexiglass, acrylics, wood, MDF and other materials needs to be laser cut, we would advise to invest in our large format laser cutters.

An extra-large work surface up to 1300 x 2500mm (1350 x 2000mm and 1500 x 3000mm options). This makes it possible to cut large objects at once.

An open bed design allows access to all sides of the table for easy loading and unloading of parts even while the machine is cutting.

The improved motion system features a rack and pinion design and powerful servo motors at each side of the laser table, ensuring the high speed and high precision of cutting.

The laser head can be automatic focus setting, making it quick and easy to change materials between different thicknesses.

With the options of high power CO2 laser and mixed laser cutting head, you can use the laser cutter for both non-metal and thin sheet metal (steel only, consider fiber lasers for other metals) cutting.

A traditional laser cutting machine is designed to work with non-metal materials only. These include wooden boards, synthetic fabrics, leather hides, foam sponges, or sheets of rubbery material like neoprene. We have created a hybrid version that can process all those things and metals less than or equal to 3mm thick, such as stainless steel, carbon steel, galvanized, and titanium plates, among others.

The co2 laser tube power is available in 150w,300w, and 600w; the laser power output is solid and stable with high accuracy processing and perfect cutting effect, requiring no after-sale service.

Wood laser cutting machines can cut various materials, including hard wood, soft wood, MDF board, plywood, and veneer. Some models can also cut acrylics, plastics, and certain metals.

This machine has a high-quality CO2 laser generator, suitable for cutting and engraving MDF. In addition, CO2 laser generators are available in various power ratings, with higher-power laser generators providing faster cutting speeds and the ability to cut thicker MDF.

The machine has high precision and accuracy and can create complex designs and delicate details on MDF.

The machine can be equipped with different bed sizes according to needs to adapt to different plate sizes.

The machine features user-friendly and versatile control software that allows easy import of design files, setting cutting parameters and adjusting settings.

The machine is compatible with industry-standard design software such as AutoCAD, CorelDRAW, or Adobe Illustrator, making it easy to import designs into the machine.

The machine is equipped with a red dot pointer that helps users accurately position the laser on the material before cutting or engraving.

This machine is not only capable of cutting MDF but also other materials such as acrylic, plywood, leather, cardboard, etc.

The machine is equipped with a cooling system that prevents the laser generator from overheating during prolonged use.

The machine can control cutting speed and power settings as needed to meet efficient cutting of different MDF thicknesses and designs.

The machine offers an automatic nesting feature that optimizes the cutting path to minimize waste.

Benefits

-

Precision and Accuracy

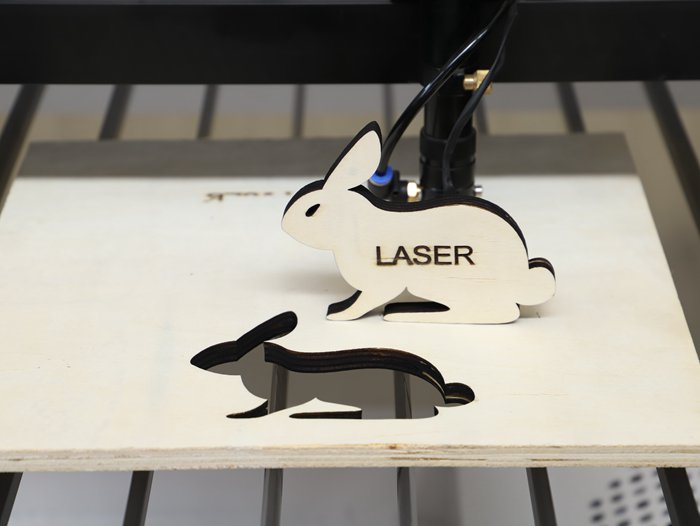

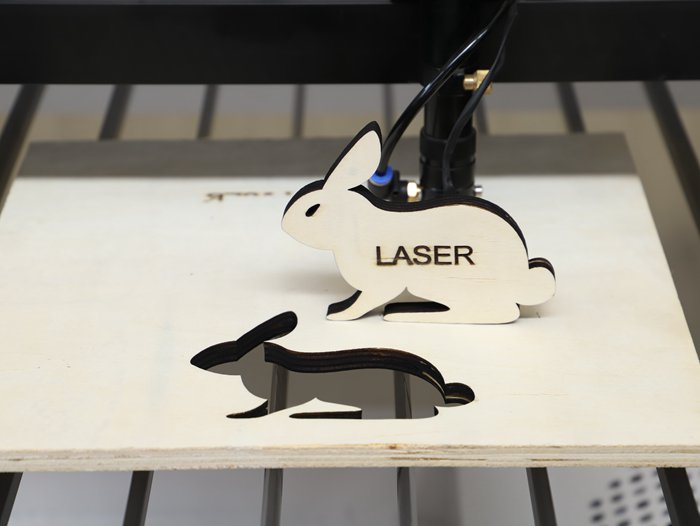

One of the main benefits of Wood MDF Laser Cutting Machines is their ability to achieve extremely precise and accurate cuts. The laser beam can cut through the material with a tolerance of just a few thousandths of an inch, ensuring that the finished product is exactly as designed.

-

Versatility

These machines can cut and engrave a wide variety of shapes and designs, making them suitable for a wide range of applications. From simple geometric shapes to complex patterns and logos, the possibilities are endless.

-

Speed and Efficiency

Wood MDF Laser Cutting Machines are very fast and efficient, allowing for high-volume production. The laser beam can cut through the material quickly, reducing production times and increasing productivity.

-

Clean and Precise Cuts

The laser cutting process creates clean and precise cuts without the need for sawdust or other debris. This not only makes the finished product look better but also reduces the need for post-processing and cleanup.

-

Easy to Use

Most Wood MDF Laser Cutting Machines are equipped with user-friendly control software that makes it easy to design and program cuts. Even those with limited technical knowledge can quickly learn to use these machines.

Applications of Laser Engraving Cutting Machine MDF

-

Furniture Making

Wood MDF Laser Cutting Machines are widely used in furniture making to create unique and custom designs. From decorative panels to intricate chair backs and table tops, these machines can add a touch of elegance and sophistication to any piece of furniture.

-

Interior Design

In interior design, these machines can be used to create wall art, signage, and decorative elements. The ability to cut and engrave complex patterns and designs makes it possible to create truly unique and personalized interiors.

-

Crafts and Hobby Projects

For hobbyists and crafters, Wood MDF Laser Cutting Machines offer a way to bring their creative ideas to life. From jewelry boxes to model airplanes, the possibilities are endless.

-

Packaging and Prototyping

These machines can also be used for packaging and prototyping. The ability to quickly and accurately cut and engrave custom shapes and designs makes it easy to create prototypes and packaging solutions that meet specific requirements.

Choosing the Right Laser Engraving Machine MDF

-

Power and Cutting Capacity

The power of the laser and the cutting capacity of the machine are important considerations. Determine the thickness and type of materials you will be cutting and choose a machine with sufficient power and cutting capacity to handle your needs.

-

Precision and Accuracy

Look for a machine with high precision and accuracy to ensure that your cuts and engravings are exactly as designed. Check the machine’s specifications and read reviews from other users to determine its precision and accuracy.

-

Versatility

Consider the versatility of the machine. Can it cut and engrave a variety of materials and shapes? Does it have features such as automatic focus and adjustable laser power?

-

Ease of Use

The machine should be easy to use and operate. Look for a machine with user-friendly control software and intuitive controls. Consider whether the machine comes with training and support to help you get started.

-

Price and Value

Finally, consider the price of the machine and its value for money. While it may be tempting to choose the cheapest option, a higher-quality machine may offer better performance and durability in the long run.

Future Trends in Wood MDF Laser Cutting Technology

-

Increased Automation

As technology advances, we can expect to see increased automation in Wood MDF Laser Cutting Machines. Features such as automatic material loading, unloading, and sorting will become more common, reducing the need for manual labor and increasing productivity.

-

Higher Power and Speed

Laser cutting technology is constantly evolving, and we can expect to see machines with higher power and faster cutting speeds in the future. This will enable even more complex designs to be cut and engraved in less time.

-

Improved Precision and Accuracy

Advances in laser optics and control systems will lead to improved precision and accuracy in Wood MDF Laser Cutting Machines. This will allow for even finer details and more intricate designs to be created.

-

Integration with Other Technologies

Wood MDF Laser Cutting Machines will likely be integrated with other technologies such as 3D printing and CNC machining to create even more complex and customized products.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.